Print failed 95% of the way into it's 60 hours 🙁

Hey guys, first post here, and wondering if anyone has any advice for me - I'm printing this hanya mask I sculpted in Prusament PLA, it's rather large. I've done a bunch of test prints that we're smaller with no real issues, got the prusa logo and benchy out looking great. However you can see that the top half of the mask failed (95% of the way into the 60 hour print!)

The mask got pushed off of the print bed so I suspect that I had a first layer adhesion issue, I did have some issues with it while trying to print it before this one; I aborted those prints after the first few layers to attempt some fixes before finally going ahead and giving it a go, here's why I tried:

- Cleaned sheet with warm water and dish soap

- Cleaned sheet with ISO alochol

- Swapped to 7x7 grid for calibration

- slowing the first few layers to 75%

- Increased bed temperature (only for first few layers) to 65

I'm printing at 0.15mm, 60 degree bed 215 degree nozzle

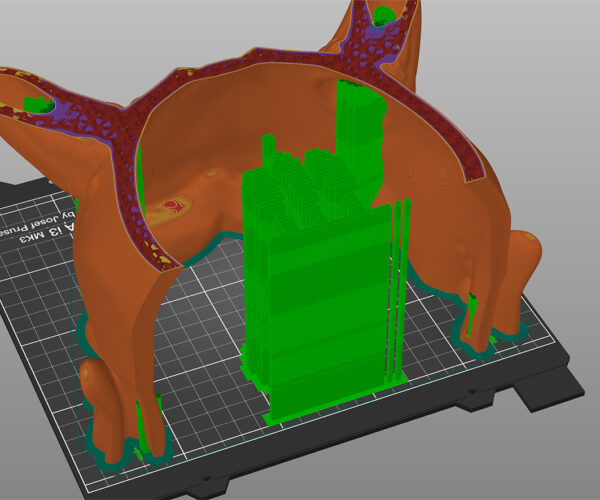

I've added some shots from prusaslicer of the set up I was using in terms of Brim and supports.

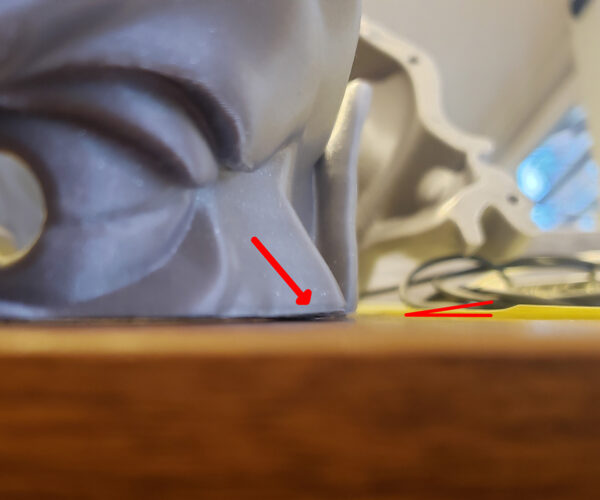

One thing I noticed is that late in the print, it started to get much louder as it was printing, I suspect (because of the lifted area at the base I've highlighted with the red arrow) that because parts of the print had peeled up and away from the bed, those parts were higher and the nozzle was actually digging into the print by the time It was close to done and this eventually just pushed it loose (it was vibrating a ton at this point). In the future I would probably decide to slow the print speed down a bunch in order to reduce the stress on the print.

Barring that though, it does seem like I have a first layer adhesion problem that only seems to show up on these bigger prints - I would really like to fix it at the source of the issue and would love to hear any suggestions. Extra adhesive? wider brim? more supports (so more surface area) using a raft?

Thanks guys!

A picture of the bottom of the print might help us diagnose.

Cheerio,

RE: Print failed 95% of the way into it's 60 hours 🙁

Hey! that's what the two photos are of the eyes, the left eye has it's base pretty solidly flat to the table, but you can see with the right eye; I've highlighted how it appears that the print lifts off the table (this happens in a few spots actuall) I can provide more pictures if theres something more specific to see?

Show us the whole bottom layer, the layer that lifted.

Cheerio,

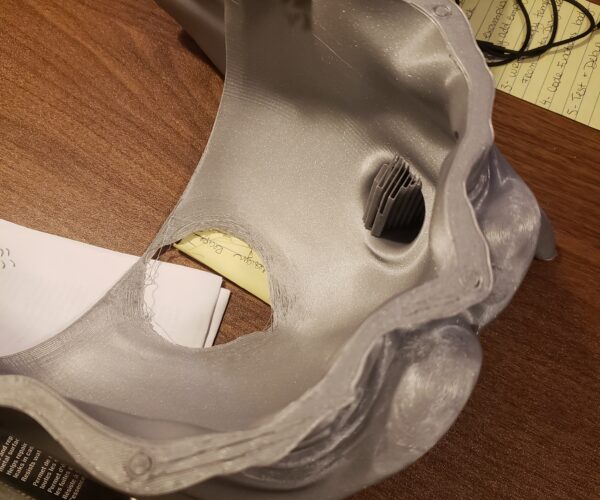

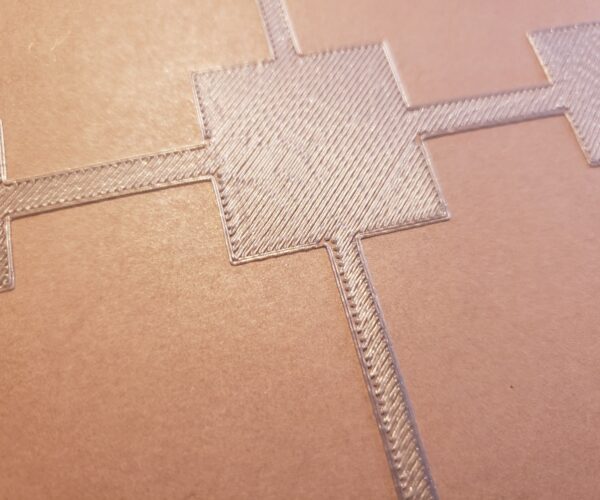

No wonder a brim helped

What have you done to get that?

RE:

That's a rather odd first layer.

Please do a first layer Z calibration print and show us the result.

Cheerio,

RE: Print failed 95% of the way into it's 60 hours 🙁

From looking at the bottom of your print I'd say your first layer calibration is putting you nozzle too high. The following pic shows what you are aiming for. See how the lines of fill snug up to the perimeters?

Mk3S+,SL1S

Whilst I agree with you @sylviatrilling I suspect there's something else as well. It may just be a filthy print-sheet but if he cleaned the sheet as stated those missing strands are, er, odd.

Cheerio,

RE: Print failed 95% of the way into it's 60 hours 🙁

Sometimes no matter how good your z-offset is or how clean your bed the laws of physics will not be ignored. As your layers build and cool it causes the model to contract and pull at the bed. If the pull is stronger than your adhesion the print will lift. A very thin layer of glue stick can sometimes make the difference. Angus at Maker's Muse had a pretty good tutorial on this.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Print failed 95% of the way into it's 60 hours 🙁

Hey guys thanks for the assists; I've added the requested images plus a few more tests. Here's the bottom of a new benchy, some closeups of my 3x3 calibration test print as well as the back of the Prusa logo (you can see a fair bit of distortion here where it looks very inconsistent.

Hoping you guys can elucidate anything from the look of stuff here!

RE: Print failed 95% of the way into it's 60 hours 🙁

Your first layer calibration is still putting your nozzle too high. This is the one setting that is essential to get right. Everything else depends on it.

Mk3S+,SL1S

RE: Print failed 95% of the way into it's 60 hours 🙁

Im curious as to how youre determining that? Not that I think it's wrong, but because I would like to be able to tell once I have it right! - Right now my live adjust Z is at -1.825 so I only have 0.175 more? (my understanding is you dont adjust below -2.00

Your first-layer Z is too high, you need more squish. I am surprised your mask stayed on the print bed for as long as it did.

Cheerio,

RE: Print failed 95% of the way into it's 60 hours 🙁

hmmmm ,what am I looking for to know its enough?

RE: Print failed 95% of the way into it's 60 hours 🙁

If you can lift your calibration print off the bed and easily separate the strands it's too high.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Print failed 95% of the way into it's 60 hours 🙁

I will attempt a lower adjust Z. If you set it to -2 and it's still not low enough what is the move?

When you say the calibration print, are we talking about the 3x3 bed levelling one? or the Z calibration print that comes along with the SD card?

RE: Print failed 95% of the way into it's 60 hours 🙁

If you need more than -2.00 live Z to get a good first layer, your pinda is too low.

reset live Z to 0.00, raise the Pinda one thread (pinda thread is 1mm pitch)

re tighten Pinda,

reset live Z

.regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Print failed 95% of the way into it's 60 hours 🙁

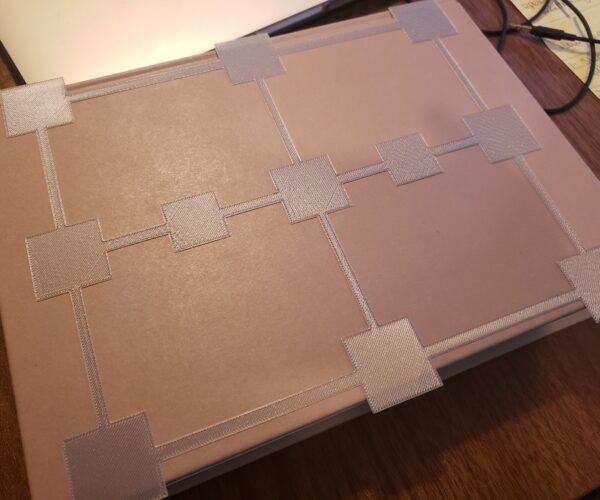

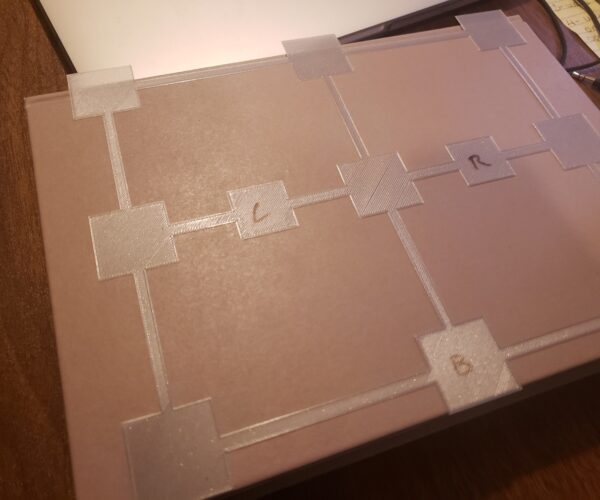

Hey guys! sorry for the picture dump, I'm hoping more info is helpful. I've decreased to -2 on the live adjust Z and the results seem much better.

The prusa logo's back, then and now

The benchy's bottom, then and now

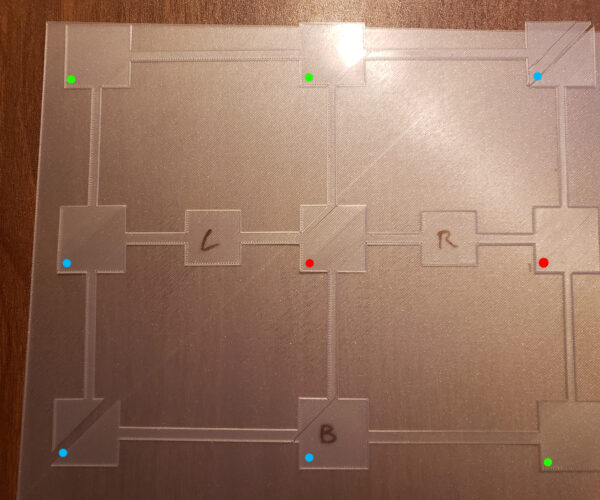

I also printed out a full sheet, there is definitely variance in the adhesion across the bed (generally the rightmost bottom corner up to the righmost center side seem easiest to pull apart.

RE:

Here is a little visualization I made from the test. I've overlayed the 3x3 calibration piece over the full bed test. The green dots are squares that I can't pull apart, using reasonable force. The blue squares did sort of 'snap' apart when that same force was used. The Red dots don't hold together well at all and almost fan apart if you sort of 'thumb' through them

In certain places you can see the table top surface through the full bed test more easily, where it appears that the results aren't as good. They seem to cluster in areas that roughly match up the areas of the 3x3 test that tended towards failure

Maybe this is going a little too deep and the results I have now are more than enough to ensure a solid print (within reasong!)Still, I'm unsure - maybe someone can glint something from this that isnt immediately obvious to me

Thank you all for your help so far