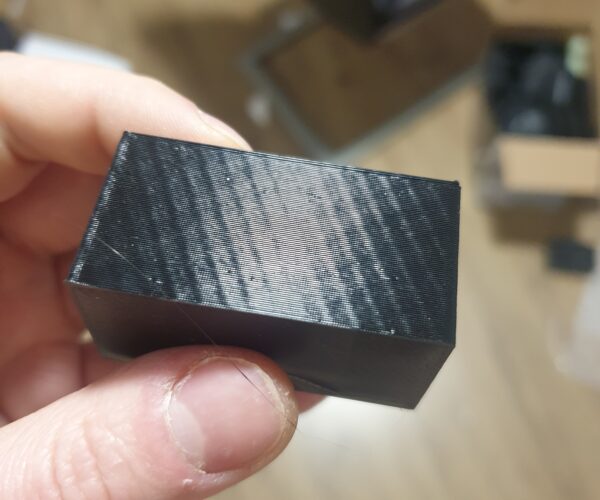

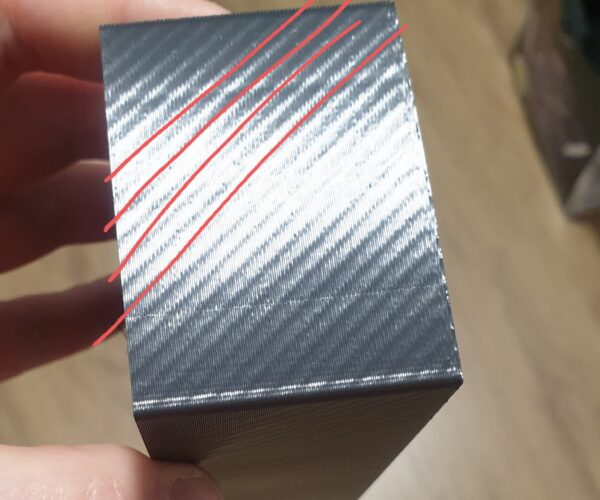

Poor quality sides throughout the model, ripples.

Hello, everyone.

I assembled my second Kit Prusa i3 MK3 +. But I noticed that the quality of the lateral surfaces on it is much worse. I didn't notice a big difference in the XY axes. All printing parameters are identical to the first printer. The belt tension is optimal in all tests, only the Selftest on the X-axis shows a value of 230, in practice it is about 265. When I pull the belt tighter, Selftest shows 210-215.

Nozzle 0,6 installed according to the instructions.

Compared to my old Prusa I noticed that the table and head move on the XY axes with little more force. The movement is uniform without jerking. Without the belt, the movements were smooth. Probably not a problem here.

Thank you for your help and your time

If this is a new build then I would rate that print as good enough for the first month.

Every user builds their printer slightly differently and pre-built models are shaken up in transit so during the first few weeks of use the printer will run-in and settle its parts together; then you will have to go over the basic maintenance checks, lubricate and recalibrate. Even if you got everything dialled in perfectly today, it would all need re-doing.

Better to settle, temporarily, for a basic working printer and get some useful printing done. When you do your one month service you can take extra care knowing the new settings on your now stable printer are likely to last for several months.

The belt tension figure is a measure of the resistance felt by the stepper when moving the axis. On a correctly set up machine this does equate, roughly, to belt tension.

But other things can affect mechanical resistance, especially on a new machine.

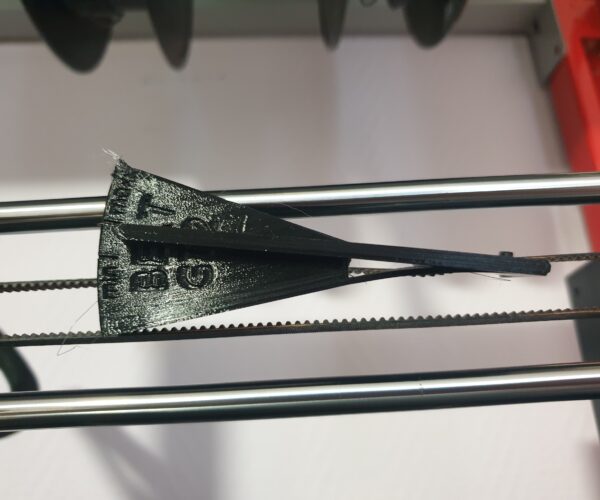

Make your next print this:

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

It MUST be printed in Prusament PETG or the spring tension will be wrong.

Let us know how you get on.

Cheerio,

RE: Poor quality sides throughout the model, ripples.

Thank you very much for the recommendations. Yes I printed that part right away, I just forgot to add a photo. This tool shows the belt tension is normal, but the printer itself during the Selftest shows a value of 230. The old printer at the same time in the same situation shows 260. I understand, I will try to print more often. I was afraid that the bearings are not working properly, but everything seems to be fine. And the resistance on the X and Y axis is the same, heavier than in the old one. So your recommendation sounds very appropriate. Thank you.

Thank you very much for the recommendations. Yes I printed that part right away, I just forgot to add a photo. This tool shows the belt tension is normal, but the printer itself during the Selftest shows a value of 230. The old printer at the same time in the same situation shows 260. I understand, I will try to print more often. I was afraid that the bearings are not working properly, but everything seems to be fine. And the resistance on the X and Y axis is the same, heavier than in the old one. So your recommendation sounds very appropriate. Thank you.

RE: Poor quality sides throughout the model, ripples.

I still think that the problem is different. I ran more tests, the problem occurs equally on both the x and y axis. I wrote to support, they wrote that I should do "Extruder linearity correction calibration". The test showed a change for the worse but no solution. I understand that the problem is most likely in the E axis. But what caused it, maybe it's a defective motor...

RE: Poor quality sides throughout the model, ripples.

Nice catch.