PLA wont stick to the PEI plater

Hello everyone,

I borought a Prusa MK3S from a friend in order to troubleshoot firts layer adhesion(he bought it around 3 months ago). I am quite certain, that the distance from the nozzel to the bed is not the problem, because the problem occurs regardless of the Z-Offset.

I noticed that even if the filament sticks to the surface it is increadibly easy to remove, even with the bed at 60°C(Nozzle 215°C), I dont know if this is normal with the PEI surface. I can only compare it to the Ultrabase of my Anicubic Mega S, on which I cant really remove print until the bed is cooled down to ~30°C.

I already tried cleaning the smooth metal sheet with ~70%Propanol and washed it in hot water with dish soap, without any success. I used the PLA that came with the printer and Prusament Jet Black PLA which prints fine on my MEGA S, so im confident that the filament is also not the problem.

I am happy to provide any additional info if needed.

Thanks in advance for any help.

Best Answer by Gurīn:

First of all, thanks to everyone for your help.

After @Diem's suggestions, I cleaned the sheet as if it was a dirty plate, again with little to no success. I probably dont have the right dish soap in house(we have no Dawn in Germany and I didnt look for an exact equivalent).

My last resort was Aceton, and it really worked wonders, adhesion is excellent now.

Image

Post an image of your first layer calibration and I will try to help.

--------------------

Chuck H

3D Printer Review Blog

Pictures of the first layer, top and bottom, would help us diagnose.

Cheerio,

First layer pictures

Thanks for the quick response,

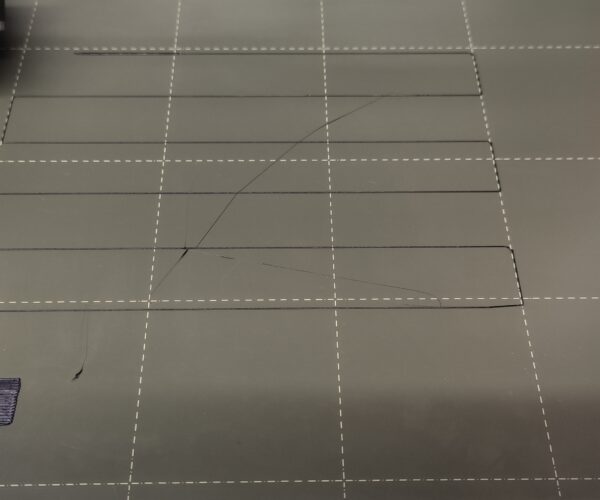

here are some photos of the first layer calibration test with live Z-adjustment. I gradually decreased the Z-offset during the last part of the test from -1.8mm to -1.6mm, I think the sweetspot is around -1.75mm(which I find pretty high).

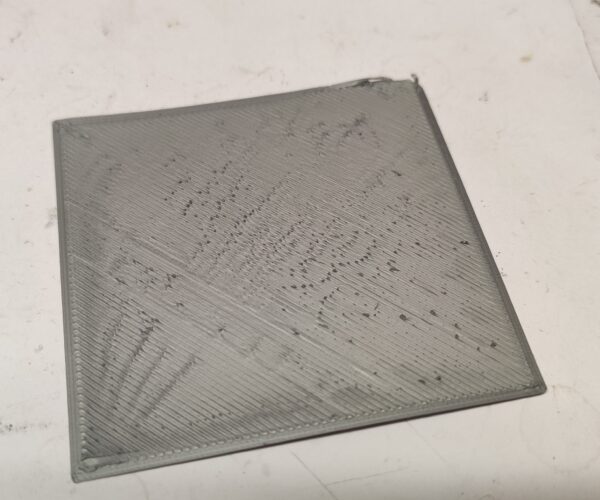

I also printed 5 squares with a single layer height(0,2mm) to compare different parts of the bed. The nozzle seems to be way to close to the bed, but this is the only way I got it to stick. I uploaded the best(backside,frontside) and the worst square(backside,frontside).

First, your print-bed is still visibly smeared, this is bound to affect adhesion.

Clean the sheet with dishwashing detergent (Dawn/Fairy) and plenty of HOT water, rinse well and dry with a fresh paper towel. Handle by the edges only.

Your first layer calibration seems to have bracketed the ideal setting.

At the end of the calibration you are aiming to print a single layer *sheet*. It should be possible to peel it off in one and fold it without the threads seperating. If it breaks into lines it is too high, not squished enough. If it is a single sheet but with wavy lines or drag marks on it you are too low.

For most people it pays to use 7x7 mesh bed levelling.

Many beginners have problems with the built-in first layer calibration routine. There are alternatives, see this page by a regular poster here: http://projects.ttlexceeded.com/3dprinting_mk3_live_z_calibration.html

and look at this thread: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

Cheerio,

RE: first layer

going off your 75 x 75 square layer I cant seem to see where you're changing the live Z height as you go ?

Personally I can tell as I alter it in stages making notes on the Z heights. then you can really dial it in once you get in a certain range.

More effectve detergent

A more effective detergent than dishwashing detergent for hand washing (N.B. not actually soap as that will leas a residue), is the stuff sold as 'rinse aid' for automatic dishwashers. Look on the back of the bottle - you're looking for something with at least 5% non-ionic surfactant.

Again use it quite warm (at least 40°C) and rinse well. After cleaning, water shouldn't 'stick' to the PEI (i.e. there should be a high contact angle). One advantage of the rinse aids it that they rinse off a lot more easily (well there's a surprise isn't it!); but they're also better degreasants.

I think I fixed it

First of all, thanks to everyone for your help.

After @Diem's suggestions, I cleaned the sheet as if it was a dirty plate, again with little to no success. I probably dont have the right dish soap in house(we have no Dawn in Germany and I didnt look for an exact equivalent).

My last resort was Aceton, and it really worked wonders, adhesion is excellent now.

Acetone

Just use it sparingly. Acetone can destroy a sheet if you use it too often or if you soak a sheet. If you use Bondtac, do not use acetone on it at all.

Happy printing.

First of all, thanks to everyone for your help.

After @Diem's suggestions, I cleaned the sheet as if it was a dirty plate, again with little to no success. I probably dont have the right dish soap in house(we have no Dawn in Germany and I didnt look for an exact equivalent).

My last resort was Aceton, and it really worked wonders, adhesion is excellent now.

--------------------

Chuck H

3D Printer Review Blog

I probably dont have the right dish soap

We suggest Dawn/Fairy because they are available to many, cheap and known to work but there are many others.

Many cheap own-brand detergents are suitable: you are looking for a medium strength, plain dishwashing liquid with no additives. Detergents and surfactants are all you need, many 'premium additives' reduce the effect so luxury brands are to be avoided.

Acetone must only be used as a last resort; it will work well but it reduces the life of the sheet.

Cheerio,

Fairy

When I lived in Germany, I bought Fairy Dish Soap. I just check online and reportedly it is still sold there.

--------------------

Chuck H

3D Printer Review Blog

same in the UK

When I lived in Germany, I bought Fairy Dish Soap. I just check online and reportedly it is still sold there.

use fairy in the uk also, never fails and keeps your hands nice and soft win win 🙂