PLA Severe stringing and blobbing on nozzle

Hi Folks.

Got a MK3S a month ago and after some simple calibration issues and some users errors (I’m totally new to 3DP) I’ve been getting consistently great prints, until the last few days.

I printed with some Taulman PCTPE nylon a few days ago with moderate results. Went back to prusment PLA and for the first time started getting stringy/hairy prints, but they were still as good as before.

Did a few pieces tonight and suddenly on my latest print the stringing has gone from very small to severe, where the first layer won’t even get down and if I can get down some of it eventually it will catch to the nozzle and end in a giant blob. I’m confused as to how it was printing quite well before this and then has just started stringing like crazy, all settings the same as beforehand. I Don’t thing its a bed adhesion issue, more so the stringiness and pulling everything with it.

Any advice much appreciated!

RE: PLA Severe stringing and blobbing on nozzle

Do a z-layer calibration.

Clean bed with dish soap.

Calibrate the first layer.

RE: PLA Severe stringing and blobbing on nozzle

Thanks Peter

Did try those but they don't seem to solve the issue of the PLA coming out so stringy

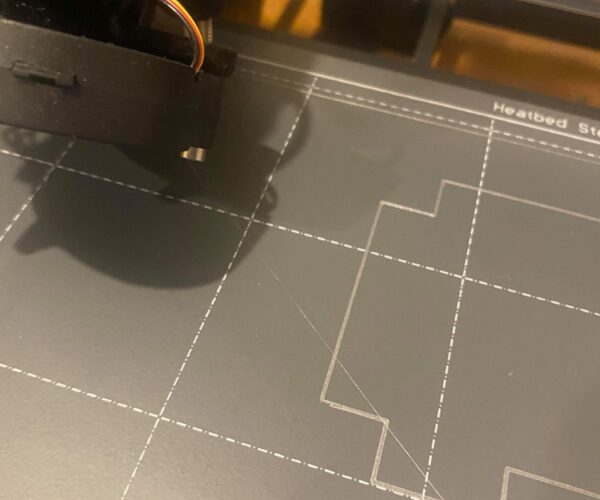

Here is a photo of a canceled first layer, you can see how much it strings all the way back to the nozzle.

Could it be a clogged extruder/nozzle?

Thanks

RE: PLA Severe stringing and blobbing on nozzle

Your possible to low.

Here's a movie on how to do a first calibration:

Most important for printing is:

Clean bed,

first layer,

both need to be 100% perfect, otherwise you can get problems.

RE: PLA Severe stringing and blobbing on nozzle

Thanks again peter

At a real loss here. I've done everything with the bed. Calibrated many times, 7x7 bed leveling, always washed with soap and water (and isoprop sometimes).

I've also now done two cold pulls to make sure its not a nozzle clog. Also upped the nozzle temp to 285C and fed in PLA make sure none of the old nylon was clogged. Tested different prints with different retraction settings.

I'm still wondering about the extruder and Hot End. The stringiness just won't go away, and it's stringing at the nozzle, not coming off print. If I pull a little blob off the nozzle it will end with a meter long string.

Also both rolls are prusament, and I've dryed them for 6 hours before attempting the fixes. Totally confused, it's been printing flawlessly for weeks, until now.

RE: PLA Severe stringing and blobbing on nozzle

[...] I've also now done two cold pulls to make sure its not a nozzle clog. Also upped the nozzle temp to 285C and fed in PLA make sure none of the old nylon was clogged. Tested different prints with different retraction settings.

Which filament are you doing the cold pulls with? Alway use the higher temp filament for best results.

Is it possible your nozzle has been damaged? Can you easily replace it to test?

PLA filament is not as prone to absorbing moisture as other types, but it can happen under the right environmental conditions. Have you tried another spool or dried your existing spool?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PLA Severe stringing and blobbing on nozzle

[...] I've also now done two cold pulls to make sure its not a nozzle clog. Also upped the nozzle temp to 285C and fed in PLA make sure none of the old nylon was clogged. Tested different prints with different retraction settings.

Which filament are you doing the cold pulls with? Alway use the higher temp filament for best results.

Is it possible your nozzle has been damaged? Can you easily replace it to test?

PLA filament is not as prone to absorbing moisture as other types, but it can happen under the right environmental conditions. Have you tried another spool or dried your existing spool?

I did the cold pulls with prusament PLA. I did think the nylon was much better being higher temp, but I'm scared of the nylon now because all these problems started after I used nylon for the first time!

I did try to take the nozzle off before, heated it to 285C, but it's so damn hard to get off with and adjustable wrench and pliers, and I didn't want to force too much pressure on the heatblock trying to get it off, so I'm going to get a socket 7mm socket tommorow for my drill and unscrew it more effectively. I used too much force and pushed the PINDA probe out, which I then had to fully re-calibrate.

As for the filament, both rolls I'm using have been fully dried. Strangely the royal blue roll was getting slightly better prints, but now it's giving similar performance to the galaxy silver one, constant strings and nozzle blobs on first layer.

Apart from a clog, what hardware problems would give this kind of behaviour? I wish I had another nozzle to test.

RE: PLA Severe stringing and blobbing on nozzle

I did the cold pulls with prusament PLA. I did think the nylon was much better being higher temp, but I'm scared of the nylon now because all these problems started after I used nylon for the first time!

Understandable, but ideally, you want to use a cleaning filament temperature sufficient to melt anything you may have printed with so built-up crud in the nozzle and hotend will melt and be embedded in the cleaning filament. Nylon is good for the higher melting temp, and it is a springy material that will pop out of the hotend without snapping.

Even better (IMO) are the specialized cleaning filaments that can be used over a wide range of filament. You can insert it at 285C to melt and grab any accumulations (and broken cleaning needles) in your hotend, trap everything as it cools, then pop out at a low (70-110C) temperature without snapping, pulling the crud with it. Cleaning filament typically advertises "foaming action" similar to detergents that will help pull accumulations away from the hotend walls, and will also melt at PLA temps if any does get left behind, avoiding a clog that a higher-temp filament might form if it does snap off. I'm a fan of eSun. I really loved the rigid.ink stuff since it would literally bubble up on extrusion, but sadly it's out of production.

I did try to take the nozzle off before, heated it to 285C, but it's so damn hard to get off with and adjustable wrench and pliers, and I didn't want to force too much pressure on the heatblock trying to get it off, so I'm going to get a socket 7mm socket tommorow for my drill and unscrew it more effectively. I used too much force and pushed the PINDA probe out, which I then had to fully re-calibrate.

Go slowly and use the E3D V6 nozzle replacement procedure. I use a 16mm open wrench/spanner & 7mm screwdriver socket. A hot nozzle can bounce into some very odd and uncomfortable places. Slow and steady!

As for the filament, both rolls I'm using have been fully dried. Strangely the royal blue roll was getting slightly better prints, but now it's giving similar performance to the galaxy silver one, constant strings and nozzle blobs on first layer.

If nothing else, you've eliminated that as a cause.

Apart from a clog, what hardware problems would give this kind of behaviour? I wish I had another nozzle to test.

A bunch of stuff. 😀"Stringing" is one of those problems that can have many definitions and many causes. Much like you, I was getting great results until I started experimenting with nozzles and filaments. More importantly, time passed any my nozzle was wearing and filaments degrading. I was convinced my printer was dying, and I was contemplating large-scale maintenance and repair. Fortunately, I identified the root causes (bad nozzle & excessive extrusion multiplier settings, along with filament moisture) early on. I've compiled a bunch of notes here that might be useful.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PLA Severe stringing and blobbing on nozzle

Thanks bobstro!

Im going to work through it slowly and thoroughly to try and solve it.

Finaly got the nozzle off, but in my foolish efforts tightened it too much instead of loosening so I hope that hasn't broken the heatblock!

I've noticed theres quite a bit of melted filament between the Heatblock and fins, is this normal? The attached photo is pretty crappy but you might be able to make out the dark blob around top of heatblock.

Now cleaned everything, seems ok but going to see if its done anything. Is there any best practice to see if your thermistor and heatblock are working properly? I really need a laser thermometer.

RE: PLA Severe stringing and blobbing on nozzle

[...] Finaly got the nozzle off, but in my foolish efforts tightened it too much instead of loosening so I hope that hasn't broken the heatblock!

You can easily strip the aluminum heater block at 285C, so do watch out for that. It's an opportunity though. I went ahead and upgraded to a nickel-plated copper block when I repaired it.

I've noticed theres quite a bit of melted filament between the Heatblock and fins, is this normal? The attached photo is pretty crappy but you might be able to make out the dark blob around top of heatblock.

That is an indicator that your nozzle was not well seated up against the heartbreak inside the heater block. If they aren't tightened well (leaving that < 1mm gap between nozzle hex and the block), you'll get leakage out the top like that. You'll want to disassemble it and clean everything up. I ran a heartbreak through the heated block a few times to clear the threads. Annoying, but 10 minutes work.

Now cleaned everything, seems ok but going to see if its done anything. Is there any best practice to see if your thermistor and heatblock are working properly? I really need a laser thermometer.

The E3d V6 hotend assembly guide has a good summary, including using a meter to test the cartridges. If you see wild temperatures, that's a definite indicator of a problem. Don't forget to do a PID tune afterward to calibrate the heating sequence.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…