RE: PLA not sticking???

When I first got my printer I was having trouble with PLA sticking. It was totally due to improper leveling. I still use hair spray for delicate prints but if what I am doing is draft work on wider objects, I don't use anything. Now I have problems with prints sticking too hard on the smooth PEI sheet - but only PETG. For that, I decreased the bed temp to 60 degrees for the first layer. The big boys at the pool hall said to keep the bed temp under the glassing temp of the PETG to stop it from grabbing the sheet. Their recommendation was anything below 80 C. Since PETG doesn't actually need a heated bed, I figured I would drop it farther at 5 degree intervals. I stopped at 60 because it was coming out well but still hanging on good enough - not making itself one with the sheet.

RE: PLA not sticking???

I've never heard of PETg 'not requiring a heated bed', as every filament and printer manufacturer I'm familiar with recommends something between 60C to 90C or so and I've had great luck printing with PETg and following the recommended (usually default) temperatures.

Now PLA can be done without a heated bed. If you look at the recommended bed temperatures for PLA, they will often go down to 25C or so, which is about the temperature of a warm room. Still, PLA always prints quite well at the Prusa default bed temperature of 60C.

I think the best practice with PETg is to always use a release agent, either glue stick or a product such as Layerneer, or hairspray. It appears that the formulae for Layerneer and some hair sprays are almost identical.

PETg usually holds very well to the PEI build plate, but it does not have the propensity to stick too well such as ABS does.

RE:

I've never heard of PETg 'not requiring a heated bed', as every filament and printer manufacturer I'm familiar with recommends something between 60C to 90C or so and I've had great luck printing with PETg and following the recommended (usually default) temperatures.

Now you have: https://all3dp.com/2/petg-print-bed-temperature-all-you-need-to-know/

Now you have [Link]

That page is an astonishing combination of out of date and completely wrong, Ignore it.

Cheerio,

RE: PLA not sticking???

Well... it might be but it also has truth. PETg doesn't need high bed temps. I have dozens of examples that I've printed. If you've tried printing it at lower temps and failed, tell us about it. I have tried and it works.

RE: PLA not sticking???

Now you have [Link]

That page is an astonishing combination of out of date and completely wrong, Ignore it.

Cheerio,

LOL, the first thing that caught my eye was the blue tape.

I think I'll continue to be guided by the default temperatures and those recommended by the filament manufacturers.

However (comma) if printing PETg with a room temperature build plate works for you, please continue to do so.

RE: PLA not sticking???

I will continue to print at 60C as I said. I agree that no heat is extreme but it was stated to explain that PETg does not need its glassing temp (80C) to stick. In fact, it should be well below that. There are many references to this on the web but I hesitate to link them since they are probably all out of date and therefore full of misinformation.

RE: PLA not sticking???

This is still an emerging craft, and different people have different ways of doing things which work for them. I say if your way works for what you do, please keep doing it and share it with others.

However it annoys me when some people insist that their way of doing something is the only way that everyone else should be doing it!

There's a lot of misinformation out there on the interwebs. There's also a lot of information that is or was true in some contexts, but may be inaccurate or invalid in other contexts. The example I think of here is the hint to freeze a Prusa build plate to make old PEI sheets easier to remove. It may have been true and valid at one time, but I can testify that it does not work with the recent Prusa smooth PEI build plates.

You can get away with a lot with smaller prints but larger ones are likely to warp badly if printed on a cold plate.

Cheerio,

RE: PLA not sticking???

You can get away with a lot with smaller prints but larger ones are likely to warp badly if printed on a cold plate.

Cheerio,

My latest issue with a warping print was on a heated plate (glass) heated to about 95C for an ABS print.

I recently also had one that cracked when it was cooling to room temperature from 95C or so.

RE: PLA not sticking???

I can see that with ABS. I hate that stuff but needs must sometimes. My discussion about bed temps was only about PETg (and off topic a bit, too!). I regularly do large(ish) prints with PETg and there are MANY problems at the recommended temps with a smooth PEI plate. I am doing one now for a 75mm motor can and sleeve that covers 2/3rds of the bed. It wouldn't come off if the temps were the recommended ones.

RE:

Somebody actually LIKED that cracked almost-one-day print! 😉

RE: PLA not sticking???

Somebody actually LIKED that cracked almost-one-day print! 😉

Me... not because of the cracked print but because of your comment - nothing like a picture to prove the point.

RE: PLA not sticking???

Never had to use blue tape.

RE: PLA not sticking???

me neither, but it does work.

Never had to use blue tape.

--------------------

Chuck H

3D Printer Review Blog

RE: PLA not sticking???

I used yellow tape with my old A8 before I installed a glass bed - worked ok. Does that count?

me neither, but it does work.

Never had to use blue tape.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: PLA not sticking???

LOL, the only time I remember seeing blue tape being used was a few years ago at our local makerspace.

One of the instructors was having a fit getting a print to stick on one of the 'toy' 3d printers (Da Vinci, IIRC) in the lab and he let out a blue streak of not so family-friendly language, grabbed the blue tape, laid down several strips on the un-heated print bed, and it worked.

RE: PLA not sticking???

PLA adhesion problems were making me crazy for weeks. I found the following YouTube video from Fred B. that finally solved all my adhesion problems...

RE: PLA not sticking???

The best advise provided on this thread was by the people who said "clean your board with soap and water." I had the exact same problems as those posted above. Great prints for the first bit then filament would no longer stick properly. I tried Isopropyl Alcohol (91%), changed nozzles, played around with heat and z axis. I finally said, hey, there's a quick easy idea. Why not just wash the board in warm to hot soapy water and let air dry. I did nothing else to it other than wash it. I did not wipe it dry or apply Isopropyl Alcohol afterwards, just let it air dry (standing vertical). Not saying it will fix your problems, but it definitely resolved mine.

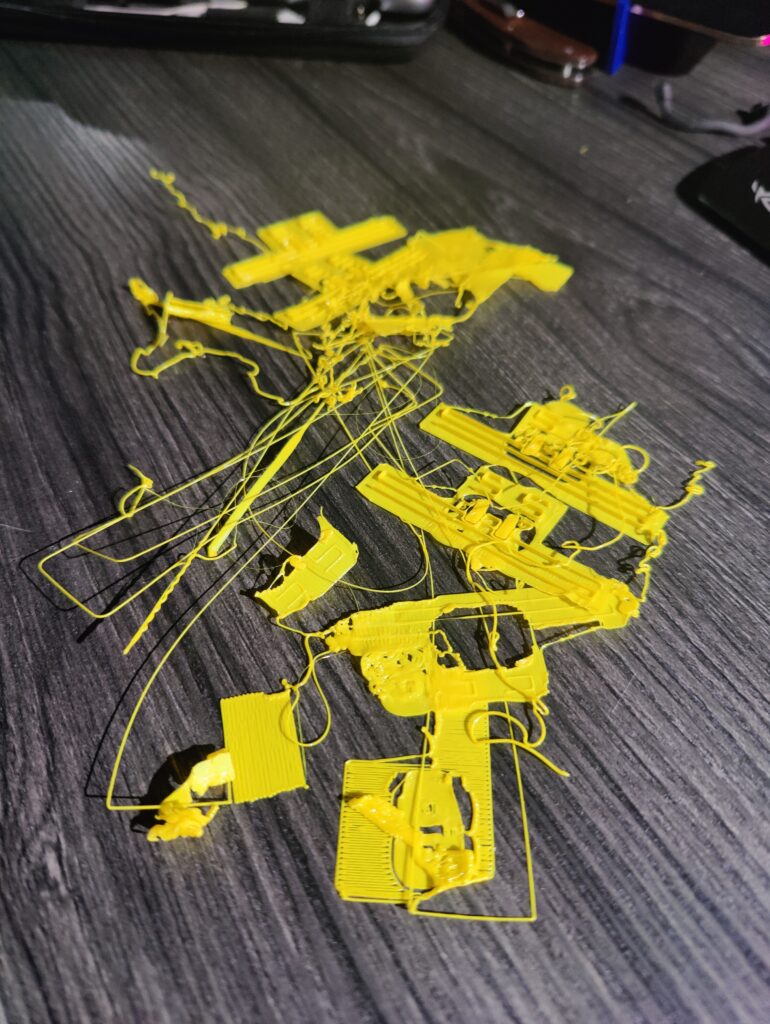

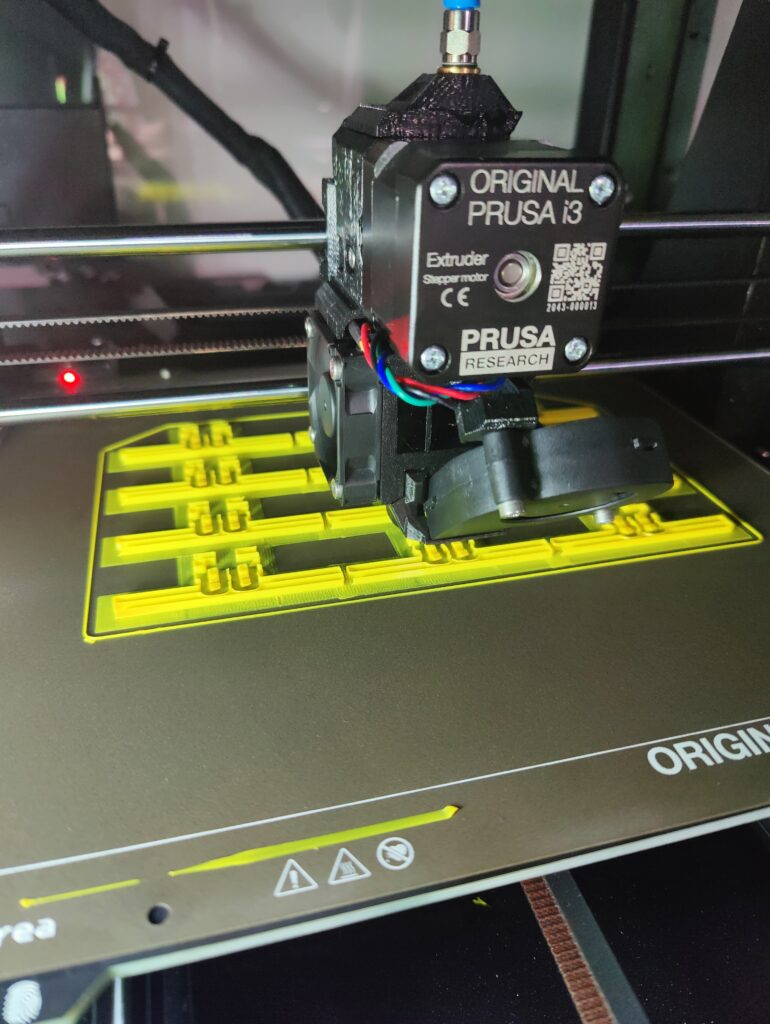

Before soap and hot water

After soap and hot water

RE: PLA not sticking???

Soap and water is amazing. It works.

--------------------

Chuck H

3D Printer Review Blog