RE: PLA not sticking to PEI Sheet

And don't just wing it with Z. Print a 2" or so calibration circle and adjust Z while it is printing. There are a lot of pictures around that show what it should look like. Lower Z until the strands just merge. The circle should lift as a smooth object when you are done. And the smooth and PC sheets are a different thickness, so each has it's own Z.

RE: PLA not sticking to PEI Sheet

I wonder if I could impose on one of the "veterans" to list the consensus cleaning procedure and the means to identify the various sheets (I for one am confused, are there 2 or 3 sheets?

RE: PLA not sticking to PEI Sheet

There are two sheets, both PEI.

The "Smooth", which is a steel plate with PEI stickers. Stickers are replaceable if you are a masochist.

The "Textured" also known as PC is a textured PEI surface that is sprayed on and baked (?). It is not repairable, but seems to last forever.

"Smooth" and "Textured" are how these are identified to Firmware 3.80 and up.

Consensus - we don't do consensus here. We each have our own opinions about everything.

Significant deviations from the Prusa line include use of water, lubricating bearings, and maybe the Prusa hot end recess that makes jams more likely.

My biases that I freely share are that:

A hot water scrub with unscented dish detergent is the first step in solving adhesion problems. Second is setting Live Z correctly.

Bearings are NOT correctly lubricated from the factory and you need to pack your own.

Hot end recess (done for the MMU) causes more problems than it fixes. If I had many jams, I would replace the hot end with a stock E3D V6 hot end without the recess.

RE: PLA not sticking to PEI Sheet

Also depending on the brand of PLA, it can leave a deposit, possibly sugary which IPA will not touch, only hot soapy water will dissolve and remove this.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: PLA not sticking to PEI Sheet

@robert-rmm200

Thanks for that. Super clear now.

RE: PLA not sticking to PEI Sheet

I learned a lot about Z axis calibration through this video.

I had no clue how much I could change this number, but going all the way down to -0.670 did the trick for me. I have now completed my first ever print after trying everything (glue, alcohol, increase bed temp, slow down the print). I am unbelievably happy now!

RE: PLA not sticking to PEI Sheet

@bobstro

Hello bobstro could you please message me the "other brand" Textured sheet? Thank you so much

RE: PLA not sticking to PEI Sheet

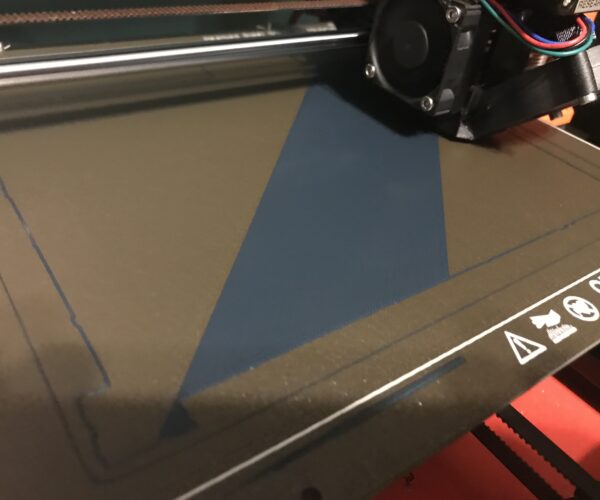

I have been trying to print a comfort grip for my switch. This thing is long enough where it needs to be placed across the diagonal to fit on the bed and has very little contact area. The length created some pretty high cooling induced stress related issues. What finally worked was printing at 230C on the hotend and 70C for the bed, then reducing the hotend temp to 215C for the remaining layers and leaving the bed temp the same. That and reducing my first layer printing speed to 20%

RE: PLA not sticking to PEI Sheet

Thank you Joan, after an awful odyssey finally my PLA prints work perfectly after a thorough cleaning with dish washing soap.

RE: PLA not sticking to PEI Sheet

@joantabb

thank you so much, i did it and now my printer works perfectly! 🙂

RE: PLA not sticking to PEI Sheet

I have been trying to print a comfort grip for my switch. This thing is long enough where it needs to be placed across the diagonal to fit on the bed and has very little contact area. The length created some pretty high cooling induced stress related issues. What finally worked was printing at 230C on the hotend and 70C for the bed, then reducing the hotend temp to 215C for the remaining layers and leaving the bed temp the same. That and reducing my first layer printing speed to 20%

Second this. I had tried everything i could find, here and elsewhere - z adjustment, hot water/unscented detergent, simple green, scotch brite pads, 99% ipa, gloves, acetone etc etc...

the one and only thing that worked for me finally was increasing the bed temp to 70C.

I have printed 4 consecutive nearly full bed prints with no wash in between and haven't had one adhesion issue withe the bed setting at 70C.

These prints were using Prusament gentleman's grey - nozzle at 215 and first layer at 70C. Rest of the layers at 60C.

Previously the first layer would always fail to adhere at some point, creating a giant mess..working great now at 70C.

RE: PLA not sticking to PEI Sheet

To add to my previous post -

It looks as though the temp reading on the printer may be a bit off. Here you can see the temperature of the bed measured with a infrared thermometer (which seems very accurate on other things i have tested) is reading 8.5C cooler than the printer indicates.

This may be a calibration issue that I need to fix and will try to do so after this print is done.

Hope this helps someone going through the same frustrations. 🙂

RE: PLA not sticking to PEI Sheet

This might seem like a silly question (I apologise if so) but for those cleaning with isopropyl, do you wait until its dry before wiping off? If so, do you have to 'buff' it to get the residue of the isopropyl off?

RE: PLA not sticking to PEI Sheet

This might seem like a silly question (I apologise if so) but for those cleaning with isopropyl, do you wait until its dry before wiping off? If so, do you have to 'buff' it to get the residue of the isopropyl off?

I swish it around wet. Ideally, you want it to loosen grease and crud so it can be wiped away. I wipe from the center of the print area outwards.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PLA not sticking to PEI Sheet

This might seem like a silly question (I apologise if so) but for those cleaning with isopropyl, do you wait until its dry before wiping off? If so, do you have to 'buff' it to get the residue of the isopropyl off?

There should be no residue with isopropyl alcohol. Any residue is either dirt or the remnants of glue stick or whatever. I mainly use isopropyl alcohol and if there is a visible residue I'll grab another clean paper towel and rinse-repeat.

Every so often I will use denatured alcohol in lieu of isopropyl, as it does seem to cut glue stick residue (and Layerneer residue) a bit better. Every so many so oftens I'll go over the smooth steel sheet (only) with acetone.

Sometimes, however, I'll re-use a coating of the Layerneer. I use this mostly for PLA prints that have tricky first layer supports. I'll take a paper towel with isopropyl and lightly rub the section coated with Layerneer, but not enough to remove it. I'll also clean off the prime strip area, which I do not use Layerneer on.

RE: PLA not sticking to PEI Sheet

Nice tips, just got a mini and I'm using 99% IPA and I'm not getting stuff sticking it was fine at first. After reading this I wished with soapy water and bam, it all sticks fine. I couldn't even do a Benchy the lettering would not stick. after the soapy waters it work.

Why does the IPA not do it and soapy hot water does ?

----------------------------------------------------------------------------------------------------------------------------

Prusa Mini+ (Ordered Dec 19,2020 - Arrived Feb 21,2021) stated clicking Mar 2nd / MP Select Mini V2

RE: PLA not sticking to PEI Sheet

[...] Why does the IPA not do it and soapy hot water does ?

Here's a quick summary:

The riddle of adhesion

You’ve probably seen some of these guidelines before and may have wondered exactly why these simple-sounding steps work. Here’s an unscientific breakdown.

-

Isopropyl alcohol 3 and acetone 4 work as solvents 1 , breaking apart grease molecules. These solvents do not completely dissolve grease but do break it down far enough that it can be removed from surfaces easily.

-

The more concentrated the solvent, the more effective it will be at a given volume. Those little 70% isopropyl wipes do work… on a shiny new PEI sheet. They’re just not effective in dealing with larger amounts of accumulated grease. This is why 91%+ alcohol is recommended.

-

Acetone is even more effective, breaking up oxidation on the PEI surface, but can make the PEI surface brittle and prone to cracking if over-used.

-

The amount of grease that any solvent will effectively break down is directly proportional to the volume of solvent to grease. The more you apply, the more grease it can effectively break down. The more concentrated the solvent, the more grease a given quantity can break down.

-

Alcohol, acetone, and any other solution you apply directly to the bed is just going to move those broken-down grease and grime molecules around. Some will be picked up by wiping with a clean towel, but some will remain on the PEI sheet.

-

A dunk under the sink with Dawn dish soap is the most effective method of cleaning. Dish soap is a surfactant 2 , not a solvent. It works in a fundamentally different way, bonding both grease and water molecules to wash away contaminants. The reason this is so effective is not because Dawn is “stronger”, but because there’s simply a much greater volume of Dawn and water and the grease is washed away from the PEI sheet.

-

Windex, a wipe of finger grease, talcum powder or specialized release agents can be used to reduce adhesion when using hot, sticky materials that grip the PEI surface too firmly such as PETG. It is still a good idea to clean the PEI before a print to get an even surface, even if you will be applying a release agent for pritning with sticky materials.

-

If you are printing high-temperature materials (e.g. PETG at 260C on a 90C bed), test to make sure it will release once cool without damaging the PEI surface. You may want to use glue stick or other release agents for these materials. Test on a sacrificial PEI surface if possible.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PLA not sticking to PEI Sheet

I personally had a lot of issues with both of my sheets powdered and smooth until I washed them off with dish liquid and hot water, even using alcohol didn't help until I used the dish liquid and hot water, since then iso alcohol (I have found 99% IPA) has been enough to clean the sheets between prints with some deeper washes here and there to be sure everything was good.

This is my personal experience so don't take it as gospel.

RE: PLA not sticking to PEI Sheet

I've personally found little if any difference between a sheet properly and thoroughly cleaned with alcohol and one that's cleaned in the kitchen sink. I almost always use alcohol, mainly because I don't have a sink conveniently located near the printers.

I'm of the opinion that it matters much less whether you use organic or water based solvents than whether you do a thorough job, as in removing the crud and particularly oils, rather than just diluting them or pushing them around.

Personally, I find it annoying that the knee-jerk response to 'my filament won't stick' is to 'clean the plate and clean it my way' instead of considering other factors, particularly that pesky Z calibration.

RE: PLA not sticking to PEI Sheet

@jsw

Ah sorry, I wasn't going for the "do it my way" response, just stating that I've had issues on fresh print beds until washing with soap and hot water. Z calibration can be pesky to get just right as well for sure usually if I'm getting issues on new types of filament I try messing with the calibration either up or down a notch or two and that usually resolves my issue when I know it was working before.