PLA doesn't stick

I could add this to the older thread, but my problem is a bit different. I have an already-built unit and when it arrived I printed out the PRUSA logo and it printed perfectly. Since then i have not been able to make a *single* print (probably 20 failures by now). I even tried the prusa logo again and it failed. Always the same: it starts laying down the base and after just a minute or two the nozzle dragging a glob of PLA around with it, with just a mess trailing behind.

I've tried: carefully cleaning the plate with alcohol [not 99% pure stuff, just ordinary] I've tried cleaning with acetone. I've washed it in dishwashing detergent. None of that makes any difference. I don't think there's a problem with Mk3 - it came assembled and printed its first print perfectly and the printer hasn't be moved since then.

Is there some information [pictures? Perhaps a test-file to try printing] that might help illuminate what's going wrong? Thanks

/Bernie\

Re: PLA doesn't stick

you can allways print up a 50/50/.2 test square. maybe you need to adjust the Z. the first layer calibration can work, but just having a 50/50/.2 square speeds things up

I have a Prusa,therefore I research.

Re: PLA doesn't stick

If the filament "rolls up" and sticks to the nozzle, the cause can be dirty bed or too high z level.

Since you have washed the bed with detergent and water (which is the best), just keep adjusting the Z level.

Even if you have purchased the printer ready-made, the Z-level must be calibrated. It's enough that you lift the printer to another location, so you may need to calibrate it.

This video will help you get started.

https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f61/the-most-important-links-original-prusa-i3-mk3-t13545.html

Bear MK3 with Bondtech extruder

Re: PLA doesn't stick

I was having issue since the room my printer in was cold. I increased the bed temp to 80 vs 60 and started using the brim function more often.

Chad

Re: PLA doesn't stick

I was having a little bit of this issue last night with one of my prints when printing solid infill really fast. I had to increase the nozzle temp and slow it down slightly. I think the PLA was cooling too quick due to how fast it was going. Fixed it by bumping up the temp by 3-4 degrees. Looks super smooth and perfect now! What filament are you using?

Re: PLA doesn't stick

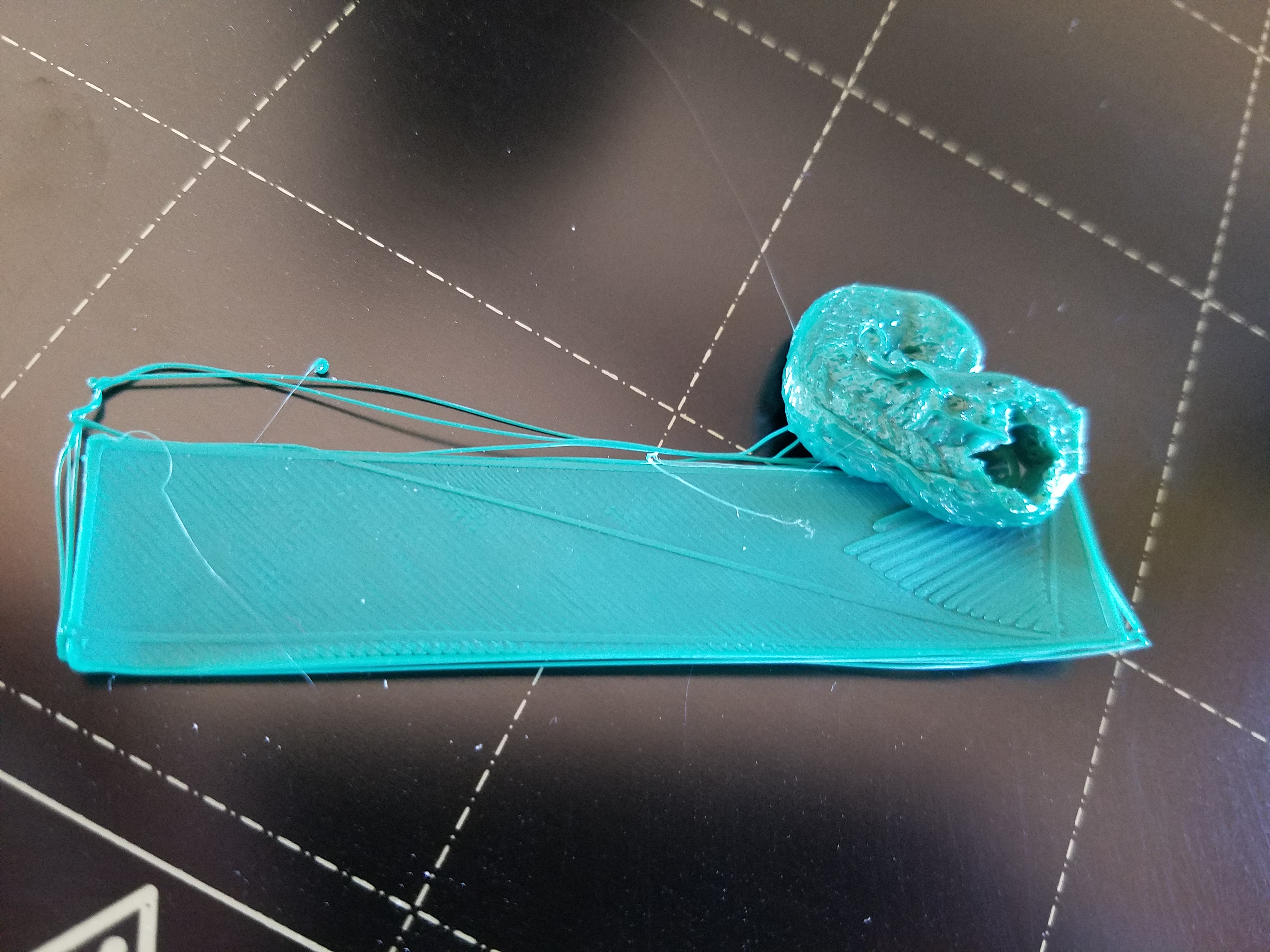

Thanks for all the advice. I did a "Z calibration" and tried reprinting the PRUSA logo and I was delighted when it *stuck*. It had done a fair bit of the bottom layer and so I went away with it happily printing. When I came back, this is what I found:

I heated the nozzle and got the partial print off cleanly and this is how far it got:

Does that give any hint as to what went wrong? Why would it gum up after getting that far? At least the base stuck to the plate this time...

/Bernie\

Re: PLA doesn't stick

Hi there, i can jump on the same train it seems.

Got my printer a week ago, and nearly since day 1 everything is warping like hell, even the XYZ Testcube doesnt stick to the bed and comes lose at some point - Realy frustrating.

The funny thing is that my first layer calibration seems to be on point, i printed 5 0.2 layers around the bed, they all had a nice flat finish and where sticking to the bed like hell, it took me 10 minutes to get all PLA Chips from the bed. I cleaned everything with soap & water and Alcohol , so there is no grease on the bed. (BTW: is it normal that the Steelsheet is this sensitive to scratches and bumps?)

Then i started a "normal" print, and as soon as the fan starts blowing at the second layer the first layer seems to just pop of and warpes like crazy - I can remove every part on the platform with no force at all.

Re: PLA doesn't stick

so the first layer is good? maybe you can lower the Z abit more.

or try the glue.

I have a Prusa,therefore I research.

Re: PLA doesn't stick

First layer seems good for me, if i go lower the nozzle starts to grind the filament creating an uneven surface, which i think should be avoided. Like i said, i have the feeling that the part Cooling Fan seems to "Shock" the First Layer - I never had such behaviour with PLA on all my other printers before, thought PLA is bulletproof against warping...

or try the glue.

Well, the thing is: I payed 800 Bucks for a printer that all i want from is producing semi nice pla prints. Not gonna start to punch glue on the bed for every new print like i got a ANET A6...

Re: PLA doesn't stick

maybe turn the fan down or off. see what happens. you on standard prusa pla settings?

I know what you mean about the glue. but it might be a good band aid until you figure it out.

I just spent 2 weeks setting up a MMU so I understand setup frustrations.

I have a Prusa,therefore I research.

Re: PLA doesn't stick

Jip is used Slic3r @ 0.15LH with generic pla settings - also i hate slic3r, but i wanted to redruce the risk of wrong profiles in S3D.

I will start to increase bed temperature by 5°C - Also its a waste of energy, because afaik PLA should stick to the bed just fine with default settings 😕 Turning the fan down results in ugly PWM Coilwhining - Noticed it when printing PETG and i dont want to hear that "beeeeeeeeeeeep" all the time 🙄

Re: PLA doesn't stick

is it making a booger when going to layer 2? just trying to throw out ideas. im awake anyhow 😀

I would test theories but my printer is busy with tool change number 3160. aka day 3.

I have a Prusa,therefore I research.

Re: PLA doesn't stick

Bernard, you may read my previous post but slipped in the main, a clean bed.

I think the most common cause of your problems is a dirty bed. As number 2 comes the wrong Z level.

Wash the bed with detergent and water, wipe with some paper and the bed is ready for PLA. Detergents and water are far better than both acetone and alcohol.

If the problems persist, they have a too high Z level. Upload an image where you can clearly see what the first layer looks like and we can provide more tips.

If the string in the first layer is round then your Z level is too high. The string should be slightly flattened and approx. 0.20 mm thick.

Bear MK3 with Bondtech extruder

Re: PLA doesn't stick

For those of us that didn't build a kit,, how do you "lower the Z? All I did was the "calibrate Z" which seemed to go OK. And what's this about glue -- I don't recall seeing that in the manual.

Re: PLA doesn't stick

Sorry, but I was a bit unclear.

By lowering the Z-level, I also mean to calibrate the Z-level.

The Z-level must be lowered so that the filament is ejected slightly on the bed and thus attaches to the bed.

If it is just laid as a round string on the surface, the filament does not cling to the bed and then the problem arises.

EDIT

And what's this about glue -- I don't recall seeing that in the manual

Glue is not needed for PLA, use it for ABS.

Bear MK3 with Bondtech extruder

Re: PLA doesn't stick

What brand filament are you using? Oh, and try using a 3M 7445 pad on the bed with some 99% alcohol. My PLA sticks super good after using that, others can chime in about it.

Re: PLA doesn't stick

Fingerprints and globs go hand in hand. Especially when I hear "first print went very well and now things are failing".

Fingerprints on the bed are the obvious place to look, but don't forget the simple fact you also handle the spool of filament and might be depositing your personage there, too. A bit of oil on the filament will cause all sort of issues as it extrudes.

PLA and normally occurring skin oils are not compatible in the print stage. And any adhesion issue is almost always the result of an insufficiently clean bed. A quick test is to apply a layer of glue with the glue stick supplied with the printer. Or buy a Elmer's school glue or washable gluestick and use it. If after applying a thin layer of glue, your PLA prints stick better, you KNOW your bed is filthy dirty and needs cleaning.

The second most common problem is improper Layer 1 calibration. Too thick a layer ... the best way to determine if you get this right is measuring a printed piece, 1 layer thick. It should be 0.200mm or 0.0079in thick. Also, if a printed layer 1 extrusion 0.008 thick comes apart as threads, you need to increase flow a bit to ensure filling gaps.

In my experience, a thin layer of PLA should come off the bed as if you are removing a good masking tape. A rigid piece of PLA needs to be pried off (or sheet bent to release it).

Re: PLA doesn't stick

Hi Bernie (and any others who share this problem, which is perhaps everybody who owns an i3 MK3...?)

If you've followed all of the proper calibration routines but are still having problems getting your parts to stick to the build plate, try scratching up the PEI surface with fine sandpaper (like 1500 grit) or an abrasive kitchen pad in order to give the parts more surface area to dig into. Clean away the embedded "ghost footprint" material from each previous print job (and also any greasy fingerprints) before starting a new one. Repeated acetone cleaning will eventually smooth over the microscopic surface roughness over time, so repeat the abrasive process monthly (or after 20-30 print jobs) in order to guarantee 100% surface adhesion success rate.

I currently have ten Prusa i3 MK3 machines running in production 24/7 and have established this technique through trial and error. When I started out with my first machine (which ironically I had named "Grumpy") I had all of the same problems that this thread is discussing, and tried lots of different solutions. Acetone seemed to help more than alcohol, but the real key moment when my success rate went from 5% to 95% was when I tried scratching the surface. I suspect that with a properly scratched surface it would be irrelevant what cleaning agent is used, and as such, perhaps other agents (IPA or soapy water) would require less frequent repetition of the scratching process.

Good Luck, and happy printing!

Lee Krasnow

IG/FB/Etsy/Thingiverse: @pacificpuzzleworks

Re: PLA doesn't stick

Do NOT ruin the PEI sheet by sanding; silly advice that will ruin the sheet. Further, if you ever intend to print PET or ABS ... well, make a video of your attempts to remove the part - I'll pay to watch it. It will be hilarious.

PLA sticks to the PEI sheet as well as good masking tape; better when warm. I have to chip PLA parts off my PEI sheet.

People sanding their beds just haven't figured out how to clean the bed correctly -- or in some extreme cases MAYBE got a bad bed. A few who have done the sanding, when they figured out cleaning is needed, tried again on a CLEAN unsanded bed (their flip side was left more or less unscathed) found PLA to securely adhere to the PEI and prints came out fine.

Re: PLA doesn't stick

Same problem here.

But with the powder coated sheet.

Althought the imprint / texture of the powder coated sheet was very visable, I lowered the Z more.

But this only helped a bit. Then I asked Prusa and they advised to increase the bed temperature from 55 to 60 degrees.

This seemed to help but today I only had to do a 2 hour print and one part came off the bed again 👿

Check attachments.

I clean the bed before every print with alcohol, but will try aceton before the next print.

Maybe it's better to buy the standard PEI sheet for PLA??

Any other advice is appreciated.

By the way, I am using Prusa Control to get from STL to GCODE