PINDA is out of align and Z calibration issue

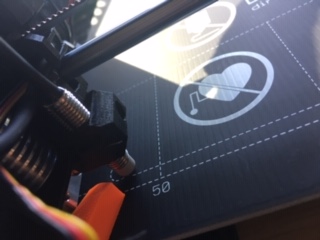

So basically just finished building the I3 MK3 kit and it went pretty well, I turned it on and it passed all of the Selftest things. Once I got past the self test it started to calibrate the Z axis which is where I ran into my first problem. Now i'm assuming that when the z axis checks out all good in the self test it means that its level and everything is fine, but when it does do a z calibration the left side of the x axis never hits the top of the printer so I don't know why this is happening. After that happens I remove the steel sheet from the bed as asked and then it starts to do the next calibration which fails as the paper gets caught on the nozzle. So I did some research and found that this most likely due to the PINDA and sure enough my PINDA was way out of wack. I've attached a photo of it after I auto home. So basically what i'm asking for is help on how to fix the PINDA and an explanation of why the Z axis is doing what it's doing.

Re: PINDA is out of align and Z calibration issue

so if you do the Z height calibration, both sides don't hit the top?

I have a Prusa,therefore I research.

Re: PINDA is out of align and Z calibration issue

I'm going to assume that when you say "during Z-calibration" you mean the step where it asks you to keep paper under the nozzle - NOT the LIVE-Z which happens later.

Also, your picture suggests you think the PINDA is supposed to be directly centered over the calibration circle. It isn't. The printer initially does not know where exactly the calibration point lies. It searches for each of the four points by circling from a safe z-height and gradually lower the x carriage. Once, it has a rough estimate of the position it does finer and finer searches until it locates the calibration point's xy. If the PINDA is physically to high relative to the nozzle, the nozzle gets pushed into the bed before the PINDA gets close enough to detect the targets. You only have only a tad over 1 mm leeway in PINDA height that works. Yours seems to be too high if the printer is behaving as your describe.

----------

OK. Let's get your PINDA physically into correct height.

TURN OFF your printer.

Place a piece of paper on the heat bed to protect it and your nozzle.

Gently lower x-carriage manually by turning both z-screws. Lower until the nozzle just touches the piece of paper. It should touch but not compress the paper.

Loosen PINDA securing bolt.

Use one of your zip ties as a height gauge for the PINDA. You'll notice that the first 1.5 or so is thinner than the rest of the zip tie. The thickness of the thinner portion is the height you will set your PINDA above the paper.

Once PINDA is at correct height, re-tighten PINDA securing bolt.

Your PINDA should now be a bit higher than the nozzle tip, but low enough that the printer finds the calibration points without pushing the nozzle too far down.

Manually raise the x-carriage to about 1/2 way up by turning both Z-screws.

Turn on printer and run calibration wizard.

The printer should move axes to find the axes end stops. It should hit physical hard stops with motions to top, left and forward.

It should no longer drag your paper sheet around while searching for the bed calibration points.

Re: PINDA is out of align and Z calibration issue

before you do the step, above, use the LCD control knob to drive the Z axis all of the way to the top.

BOTH X axis ends should bump into the Z axis top brackets to level the X carriage.

you engage the Z axis motors by turning the printer on, waiting for the screen to settle on the normal information screen, then

pressing and holding the knob down until

Z: xxx

appears on the LCD

then turn the knob untill the X axis ends both bump the Z axis end supports at the top

if one X axis end gets there first, and the Z motors stop driving, you have probably reaches Z - 210mm. in this case, turn the printer off, wait 5 seconds or longer, turn the printer back on, and continue driving the Z axis upwards until both X axis ends have rattled against the Z axis top supports...

then continue with the adjustments in the previous post

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: PINDA is out of align and Z calibration issue

Thanks for all the support, managed to fix all issues thanks to all your help!

RE: PINDA is out of align and Z calibration issue

Thank you so much!

This tips saved my day. 😀 👍

Prusa MK3S is working fine now.

RE: PINDA خارج مشكلة محاذاة و Z المعايرة

@joantabb

can you tel me about Z: xxx

what it means

move z axis until 000

or what

can you c tell me with picture

RE: PINDA is out of align and Z calibration issue

@joantabb

I can't thank you enough for your detailed solution. Both Z top endpoints must be hit hard for the calibration to succeed. I would say this is a firmware issue which causes a lot of headache.

Thanks again!

RE: PINDA is out of align and Z calibration issue

Hi there. so Ive completed the assembly of the mk3s+ yesterday, and I've been trying to go through the calibration process about 15 times so far.

doing belt tension changes, pinda height adjustments, Pinda sensor test, manual max Z travel on X, and paper to nozzle test... over and over.. many videos, many Blogs.. all great suggestions.. but I still come to XYZ calibration failed, bed calibration point not found..

this is the 3rd machine I've put together and it's the first plus machine... also the first one with issues.. now that the belt tension screw has been removed on the X... it's a bit more entertaining to adjust IF its an issue...

while I write this I'm doing a calibration again... (oops... it failed again.. )

I'll keep trying to solve, but.. I'm more likely to return the unit to the shop that I bought it from

RE: PINDA is out of align and Z calibration issue

updated firmware... all (dec 18 2020) and it worked awesome..

Thank you Voxel in vancouver bc

RE: PINDA is out of align and Z calibration issue

This happened to me on the first Z calibration just yesterday. @joantabb 's solution is what solved it for me. Drive the z up using the manual drive in the menu. My machine thought Z +210 was about halfway up. Good luck!

RE: PINDA is out of align and Z calibration issue

@kelico I'm having issues, too.

When I first assembled, x was 243 and y was 254. It flew through calibration wizard without an issue. Measured skew was 0.02 (L 11.15mm, R 11.07mm) I had good adhesion and first level print calibration did fine. Then I moved past basic prints to a bigger (taller) one and it was not good. Very inconsistent layers. I suspected my X-axis was to blame based on the way the layer were sitting. So I adjusted the belt.

Then everything fell apart. I swear. The belt tension has been all over the place, but what's weird is that I cannot get it to pass the XYZ calibration setup. I've tested the PINDA, made sure all belts and screws are tightened. I ran through calibration over and over. If I do a belt test, it is fine. Auto home is fine. The nozzle doesn't drag the paper and will move to all four points. I used the ZIP tie to properly measure the distance from the plate and the PINDA, which triggers when I place a metal spatula beneath it.

Then I saw folks recommend the software update, so I did. Now I am reading a skew of 0.5 !?!?! I don't know how it went from 0.02 to 0.5. I only adjusted the belt tension. A butterfly sneezed and now the whole thing fails when I run the wizard. I even did a factory reset, re-installed the new software and tried @joantabb method for moving the Z. I have done nothing structurally to change this to affect the skew. When I go in to measure everything, it squares/lines up so I don't see a way to manually adjust anything there.

I have run through calibration over and over.. I have watched many videos, lurked here on the forum.. all great suggestions that i have looked into and crossed off the list. But I still come to XYZ calibration failed please consult the manual or bed calibration point not found error message when I begin the wizard (they alternate). Again, I can't see where the problem is. Everything measures up with level, the bed calibration passed just fine the first time through. The tensioner is different on the plus, but I went back and followed the instructions, and made sure I was doing it correctly. Now it is at 183. I won't know if this is good/bad or not because I cannot get it to move past the bed calibration. I know it didn't print well at 243.

This is the 2nd machine I've put together and it's the first plus machine... also the first one with issues.. my other Prusa never gave me these problems. I think I have tried just about everything, and I am getting really frustrated and disheartened. What am I missing?

Update: I checked again just now and now the skew is showing at 0.03. I have no idea what happened there. But it looks good now. Wizard is still failing after the self test when it moves to bed calibration. All axis look good, move freely and All SEEMS fine. I am stumped.