PETG textured hell

So I have my mk3s a little while now. PLA printing on the smooth sheet has been like a dream. Ran the calibrations , and it just works, regardless of whether it is a full bed print or small things, and with multiple filament brands. 100% ok everytime. Perfect.

Trying to print prusament petg on the textured sheet has been hell. It will not stick.

This is what I have done:

Calibrated for the different z height with the textured sheet

Cleaned with 95% ipa on a cold bed, and then not touched the bed before warming and running the print.

Calibrated the first layer multiple times, it sometimes does not stick, tried going higher and lower to see if it was an incorrect height , no difference, tried +\- 30 in increments of 3

I was very careful to build everything level and straight, the skew compensation says it is perfect

Always ran with 7x7 mesh bed levelling.

Tried another brand of petg

Tried different z heights via live adjustment, both closer and further from the bed.

The slicer options are the prusament petg defaults. Every time, there are first layer sticking issues, the filament just does not stick consistently. With curling at the edges, or lines just not extruding, or partly sticking on one side, and then not on the other. It is not consistently the same side with issues.

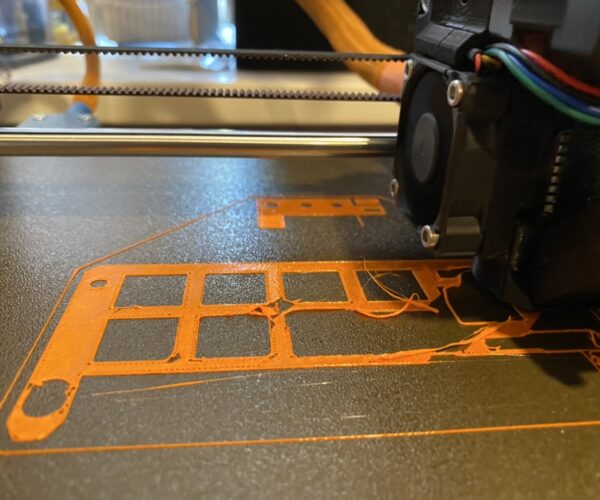

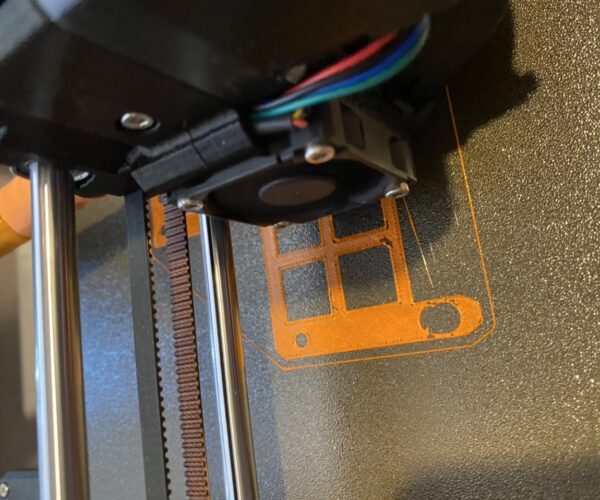

There are no blobs of petg on the nozzle when it happens, here are some photos of a print of some of the mmu2s parts.

I don’t thing it is a bed level issue, as I have had not problem with full bed prints with the smooth sheet and pla.

Does anyone have any suggestions? (Aside from using petg and the smooth sheet, which I don’t want to do as it is messy and if you get it wrong will stick like superglue) At this point I don’t know whether to return the sheet, or move to using buildtak, which works well with petg on my non prusa printers. Here are some photos of my latest fail, just as i stopped it part way though layer 2.

Best Answer by JoanTabb:

Have you tried giving the build plate a damned good scrub, with washing up liquid and hot water, then rinse well with hot water and dry immediately with a paper towel. ?

Regards Joan

RE: PETG textured hell

Have you tried giving the build plate a damned good scrub, with washing up liquid and hot water, then rinse well with hot water and dry immediately with a paper towel. ?

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PETG textured hell

I haven’t tried water as Prusa said not to due to rust, then again there is not much too lose, as it is useless at the moment anyways. Thanks I’ll give it a try.

RE: PETG textured hell

https://help.prusa3d.com/en/article/i3-printers-regular-maintenance_2072#rods-and-bearings

if you read enough knowledge base articles you will get conflicting information.

the end of the above article, and if you follow the link at the end of that article to the build plate preparation article, you will see them recommend washing the build plate... just don't stick it in the dishwasher and leave it there in the damp!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PETG textured hell

@joantabb

Hi this is exactly what i have found, I print alot in petg using a smooth plate.

oh boy get it wrong and it sticks

I have done just the same as you have, thought it was me going crazy, all i seem to get is it rolling up into a ball.

my next move was to wash it, normally i do was them before i use them

Graham Fox

RE: PETG textured hell

Same problem here. I can get things to stick, but baaaaarrreeeelllly. I'll try scrubbing it tonight, but does that mean giving it a good scrub before every print? Or just when you first get it?

RE: PETG textured hell

Same problem here. I can get things to stick, but baaaaarrreeeelllly. I'll try scrubbing it tonight, but does that mean giving it a good scrub before every print? Or just when you first get it?

Wash it starting out and whenever adhesion starts to fail. Do nothing else.

The more carefully you avoid contamination, the longer wash intervals can be.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: PETG textured hell - Problem now sorted

Thanks for your help Joan, I gave it good scrub for 5 minutes each side with hot water and dish soap, and now the first layers are going down a treat. All sorted now, I wonder what was on it that IPA wouldn't shift but dishsoap and water would?

RE: PETG textured hell

@mcmadhatter

IPA dissolves some greases, but if you don't use enough paper towels and enough IPA, what you actually do is thin the grease out and spread it more evenly across the build plate, rather than actually removing it. IPA doesn't dissolve other forms of contamination very well

the dish soap is actually designed to remove grease and water soluble contaminants and it binds them into solution with suffactants, rinsing removes the remaining traces of soap and the suspended contaminants

Magic, Eh!

And as long as you dry the water off, there is no lasting damage to the steel plate

Some forum members get all uptight about washing the painted steel plate and drying it, but they happily leave their Painted steel cars out in all weathers all year round , Hey ho... if you want to learn from others experience, there are opportunities every day Lol!

if you look at the maintenance knowledge base article, the last paragraph talks about washing the PEI

https://help.prusa3d.com/en/article/i3-printers-regular-maintenance_2072#rods-and-bearings

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PETG textured hell

@joantabb

Thanks Joan! Washed the guy last night and it's sticking a lot better! Not quite as good as smooth PEI, but I really like the finish from the textured plate. Thanks for the tip!

RE: PETG textured hell

If you print with PLA onto the textured sheet, it can leave residue (sugars) which IPA will not touch, and will prevent PETG from adhering to the textured plate.

The only way to dissolve the residue is with hot water, the dish soap will also shift any grease that has got down deep into the texture.

As stated, rinse it and dry it as best as you can then dry it further on the printer by setting the bed heat to 110 Deg C and allow to sit at temperature for at least 10 minutes, turn over for a further 5 minutes and you will have a very clean and dry build plate with no possibility of rust forming as there is no water left, any residual water that may have got in deep into the texture will have boiled off.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: PETG textured hell

@joantabb

Thank you so much for this suggestion. I was pulling my hair out trying to print Prusament PETG on a textured sheet with my second MK3S printer. Nothing worked until I prepared hot soapy dishwater and gave the textured sheet a good scrub with a clean dishcloth. Dried it off, put it back on the print bed, and now the PETG prints like a champ on the textured sheet!

They should really put this maintenance tip in the next version of the Print manual.

Thank you!!!

RE: PETG textured hell

Cleaning is important, you could try a few prints cleaning with alcohol, then use dish soap again.

Switching filament pla to petg or abs, clean bed with dish soap.

Also first layer calibration is important, then sticking is optimized, and prints do not get loose and stick to your nozzle.

Small prints with only a little part on bed always clean with dish soap and use glue stick and big brim, for big flat parts the same.