Part thickness innacuracy.

Hi and thank you for the help.

Every parts I print, which are mostly flat parts, have an error of 0.3mm thickness.

If I print something 4mm thick, it will result in a 4.3 mm thick part.

10mm will be 10.3mm etc.

Not sure where the shift comes from. Thank you

Is this a bridged layer?

Is the flat surface bridged (supported) by any chance? The current version of PrusaSlicer includes a bridging layer that increases part thickness by roughly that amount. If so, the good news is that the current alpha release has a new approach.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

no bridge

It is not. I have even draw a perfectly square and flat piece, nothing but a 50mmx50mm square, with a thickness of 4mm. And the printer made it 4.3mm. The width also show inaccuracy or around 0.25mm (50.25mm)

More information needed

What resolution did you print it in? What is the modeled part height? What is the first layer height set to in your sliced GCODE?

The printer will not print half layers, the # of layers is a simple arithmetic sum of the bottom layer height, and the resolution layer height multiplied until the sum of the two exceeds your planned height. If you want to get .3 precision, use .3 layer height. If you want .1 precision, use .1 layer height.

layer height

Thank you for your help Dan.

Strangely I am printing at 0.07 mm layers, the total thickness is 4mm. I don't see why I would get 0.30mm errors

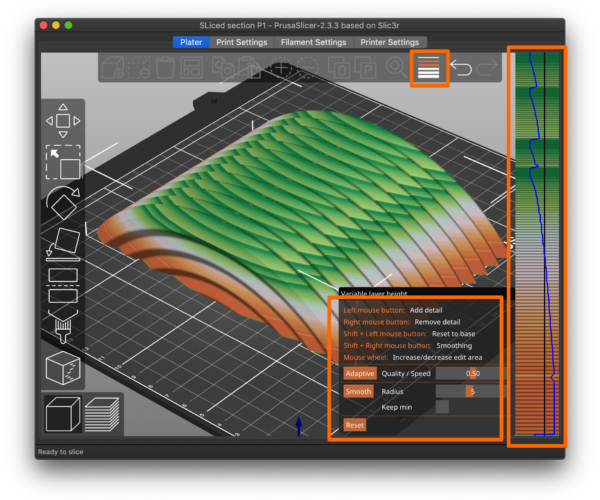

Variable layer heights may help

[...] Strangely I am printing at 0.07 mm layers, the total thickness is 4mm. I don't see why I would get 0.30mm errors

If you select the part in Plater view and use the Variable layer height button at the top, you can get a more exact match on layer heights. You can adjust level of refinement with the slider. I use this on vertical parts frequently to use a higher layer height to speed up printing, with the top-most layers adjusted to thinner heights for accuracy. Here's a summary of the procedure:

- Select the part and click on the variable layer height button (horizontal "hamburger" bar button) at top.

- Adjust the sliders in the variable layer heights setting box and click Adaptive to see the results.

- You can view and tweak the layer heights in the vertical bar at right (left & right mouse button).

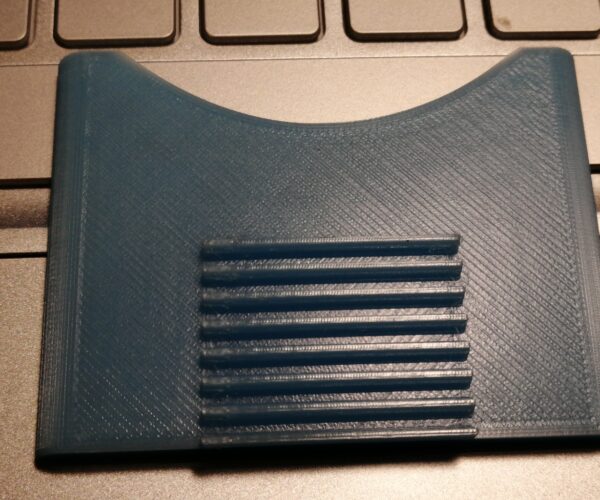

As to why you're getting such a large variance, hard to say. Save your current 3MF project file, zip it up, and attach it to a reply here so we can see your part & settings and give better recommendations. A pic of the underside of your print would also be helpful to possibly identify 1st layer issues.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

parts for evaluation

Thank you for your help, as much as I scratch my head, I don't see any way to attach anything but images and medias in an answer here ...

zip

You need to zip your .3mf in order to attach it to a post.

Mk3S+,SL1S

Part for verification

Here is attached my 3mf and a picture of the part

No Part... no .3mf file

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Must zip file, then attach it

Thank you for your help, as much as I scratch my head, I don't see any way to attach anything but images and medias in an answer here ...

You need to save the 3MF project file and zip it, then attach using the Choose file button below the edit box.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Look down below...

Up above the text entry box is add media. Down below the text media file is Attach file. But you will not be able to attach your post-slice then save prusa slicer file (.3mf) unless you first right click on that file in your computers file explorer, and send it to a compressed folder. This is what people often refer to as "zipping it". The add file button will let you add zipped (compressed) files. If you would use add media to attach your pictures, and attach file to attach your zipped file, we can start getting past how to use the browser interface.

Can you zip up the Prusa Slicer project file

Open your slicer project file (hopefully you saved it after you sliced the thing you are trying to print). To make sure it contains the settings you used to generate Gcode file for printing, hit slice now. Then when it is ready and the stats window is complete, use File menu/Save Project - and save those settings into a .3mf file. Zip that up and load it so we can see it here. The OBJ is not helpful in diagnosing whether there are any settings out of whack as part of the .obj --> .stl --> .3mf --> .gcode process

You seem to have supports turned on but autogenerate turned off and there are no supports painted on or enforced

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Deviation in slicing or actual prints?

It is not. I have even draw a perfectly square and flat piece, nothing but a 50mmx50mm square, with a thickness of 4mm. And the printer made it 4.3mm. The width also show inaccuracy or around 0.25mm (50.25mm)

I just sliced a 50x50x4mm square using your settings. It shows it slicing at 3.98mm using your defaults. With adaptive layer heights applied, it shows 3.99mm. Are you seeing the 4.3mm result in the slicer preview after slicing, or only after printing?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

slicer versus reality

The slicer will give me thicknesses like 3.95-3.98.

Still the end result is 4.15-4.30

slicer versus reality

The slicer will give me thicknesses like 3.95-3.98.

Still the end result is 4.15-4.30