P.I.N.D.A Adjustment and first-layer calibration

I finished the assembly of my Mk3s Yesterday and since I wasn't able to get 1 good result with the first layer calibration. (I tried at least 24+ times.

Here's some info about my machine:

- XYZ calibration result: Perpendicular

- Skew: 0.05

- Belt-x: 2.65

- Belt-y: 2.76

- All sensors: O.K

- Z-adjustment: I tried almost every values ranging from [-1.465 to -0.985] mm

- Material Used: PLA Galaxy Silver - Prusament

- Sheet: Textured powder coated steel sheet

The main issue is adhesion. Whether I increase or decrease the z-adjustment, my first layer always gets messy when moving from the x movement to the Y movement and vice-versa. Sometimes the whole line sticks to the nozzle.

I have the textured powder coated steel sheet which have been cleaning with IPA 99.9% between every tests (and yes I waited for the sheet to be cold before cleaning).

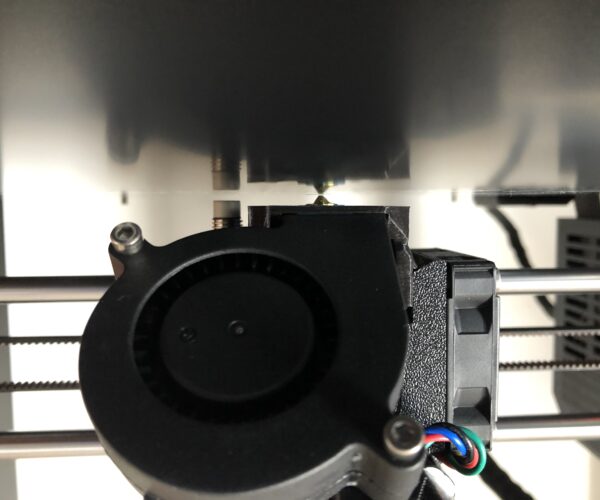

I tried to re-adjust the P.I.N.D.A which I'm still unsure if it's correct or not, base off my previous results. Here's a picture:

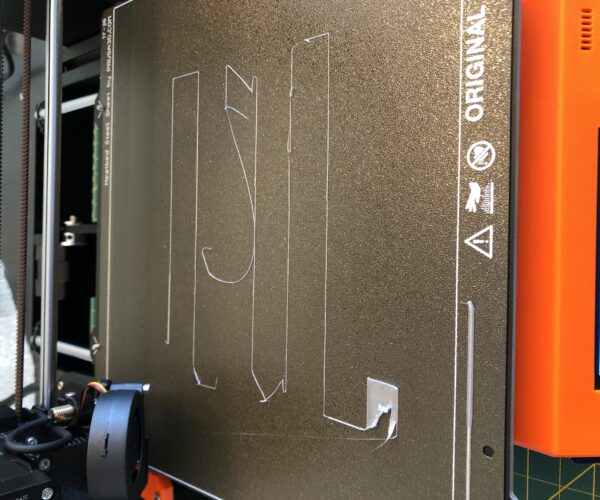

Below one of my most average result.

I don't know what else I can do.

RE: P.I.N.D.A Adjustment and first-layer calibration

I wash my textured build plate with Dish Soap and water, not IPA,

and I use the 'Life adjust 'Z' My Way', process for live Z

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: P.I.N.D.A Adjustment and first-layer calibration

New steel sheets hold filament not as good as old ones, so clean with dish soap a few times.

Your picture it looks like you need to go lower, a little. You could also heat the bed a little more, and filament a little hotter with first layer.

A new sheet will stick less then a used one.

PLA sticks more difficult on a powder coated sheet. Is still possible settings need to be more preciese.

This how I work on a pei sheet(there are always exceptions):

Most important to 3d printing is:

1. 3d print will never be like start and i have the print, there will always be problems!!!!!!

2. A clean sheet, use dish soap, then you can print on it. A few prints you can use alcohol, then again dish soap,

big flat models and models with small footprint on sheet- use glue stick(and not every glue stick is the same,

use one that makes a thin layer), and big flat models and small footprint, use a big brim attach to model so footprint is bigger.

Petg sticks to much on the pei sheet, use window cleaner, this leaves a layer on the bed, so it does not stick to much.

3. To get it stick very good, a 100% first layer is very important, see youtube for movie on this.

Every new print watch the first layer, and look if it is 100%, this will also prevent a big ball of filament on your nozzle wenn model let loose during printing.

Extra: (normally not needed).

First layer, print hotter.

First layer slower.

Bed more heat.

Most problems are first layer to get this 100%.

Bad filament is possible, or filament with water inside.

Move extruder to the top and extrude filament, it should go straight down(if not, nozzle possible blocked),

it should be thick enough(if not, nozzle possible blocked), (do a cold pull),

if Bubbling during extrusion then it has to much water inside.

Check after the first layer is ready, then you see if it sticking enough, and not releasing and sticking to the nozzle.

Use 7x7 calibration for first layer, see settings in the printer.