Over-extrusion - seems to come and go

I'm having an issue with this periodic globing which is occurring with the PLA (below) and PETG. With this PLA (GEEETECH), I'm seeing a glob forming every 2cm or so. I started this print at 210 but increased it to 215 to if a reduce viscosity would help. I also reduced the extrusion multiplier to 0.9 mid print, but it didn't seem to help.

I am mostly taking the generic PLA defaults otherwise without retraction. The only non-default I use in the mk3s+ settings is I slow the first layer down a bit to 10mm/s. No real issues with the first layer adhesion.

This is a fairly new nozzle. In my build, I had to replace the heat block. I've since reinspected it and I don't see any issues with the hotend.

I welcome any thoughts at what to pursue next. Am I still printing too hot/cold? Should I continue to reduce the extrusion multiplier and if so, how low is normal?

Bruce

RE: Over-extrusion - seems to come and go

is there filament on top of the Heatblock?

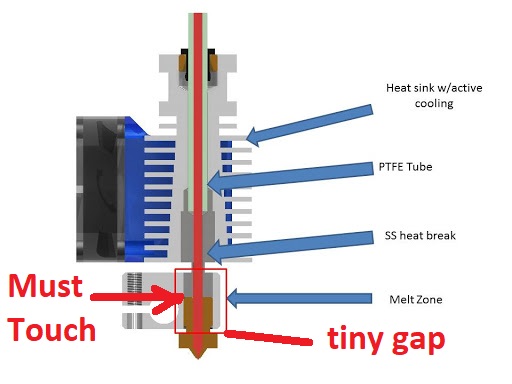

sometimes this happens when the nozzle is changed and the heatbreak is not tight against the nozzle

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Over-extrusion - seems to come and go

Thank you, I'll will inspect these parts. I do remember the nozzle did snug up when tightening, but it's possible some filament was blocking. So, I'll remove the nozzle and warm the nozzle to ABS temps, wipe it clean and re-seat it.

Bruce

RE: Over-extrusion - seems to come and go

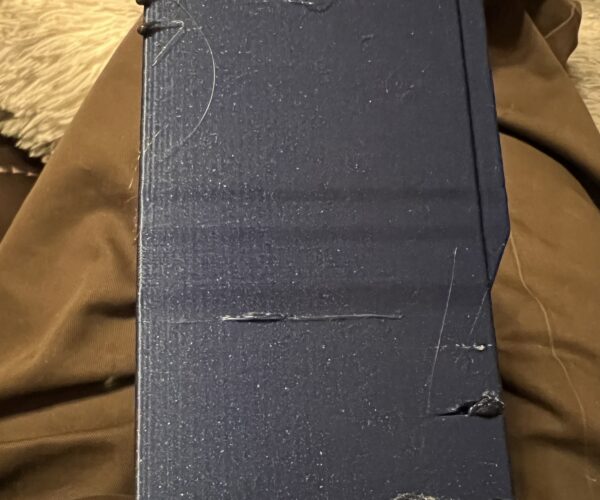

Ah! In taking off the fan and shroud, I could not detect a gap between the heater block and nozzle but I also noticed that the globbing I'm seeing may not be coming from the nozzle at all:

So molten filament is coming from above the heater block it appears.

I'm not sure exactly what this indicates. I'd appreciate any assistance. Was the nozzle installed incorrectly? The PTFE tube incorrect?

Thank you! Merry Christmas!

RE:

See the pic that @joantabb posted. The nozzle needs to seat tight against the heatbreak, which is screwed into the heat sink and the heat block. When it’s properly torqued, there should be a small gap between the base of the hex on the nozzle and the heater block, as in the pic. The heat block has to be at print temp to fully tighten the nozzle.

RE: Over-extrusion - seems to come and go

Thank you! I was wondering if there were any other potential causes that I could investigate while I'm removing things.

Good news, I removed the nozzle, heated up the hot end, then replaced the nozzle, nice and tight. No more globbing!

Let me pass along some details in case this helps someone...

The nozzle LOOKED snug to me, and when I previously tightened on the nozzle it tighten snug. So, it surprised me when the suggestion came that the nozzle wasn't tight against the heater block. The only thing can guess is that there was some hardened plastic blocking things that made it FEEL like it tightened snug, even though I'd heated the heater block when I replaced the nozzle.

Turns out, I don't think that I heated the heater block enough. I'd used PLA and PETG filament, but when I replaced the nozzle, I heated it for PLA, which would have left any PETG unmelted.

What I did to ensure snug tightening of the nozzle the second time is that I threaded on the nozzle a few threads, then heated the hot end to ABS temps (hotter than for PLA or PETG). Once it got to temperature, I threaded on the nozzle the rest of the way. Over the next few minutes, I checked the tightness of the nozzle a couple of times. As the hotend stayed hot, I could tighten the nozzle a little bit each time (1/20th) of a turn or so.

Following that procedure, the globbing appears to be gone.

I welcome anyone's comment on my procedure for tightening the nozzle to ensure I get a flush, tight seal.

Thank you @joantabb and @randym9 for the points in the right direction!

Bruce