Need some help to fine tune for small parts

I was reasonably happy with my first print although I knew I still had work to do. My problem now is that very small areas of base layer tend to curl up a bit which makes them easy to dislodge. I also have an issue that (to me) seems like a little a bit of over extrusion which affects small sections of top layer. I'm wondering if the over extrusion problem is adding to the lack of adhesion problem because the scaggy endpoints get caught and dragged so if it's a small piece with iffy adhesion then it just lets go? I should add, I'm using the smooth PEI plate which has been washed with soapy water and is cleaned with IPA before every print using a microfibre cloth.

Hope you can help 🙂

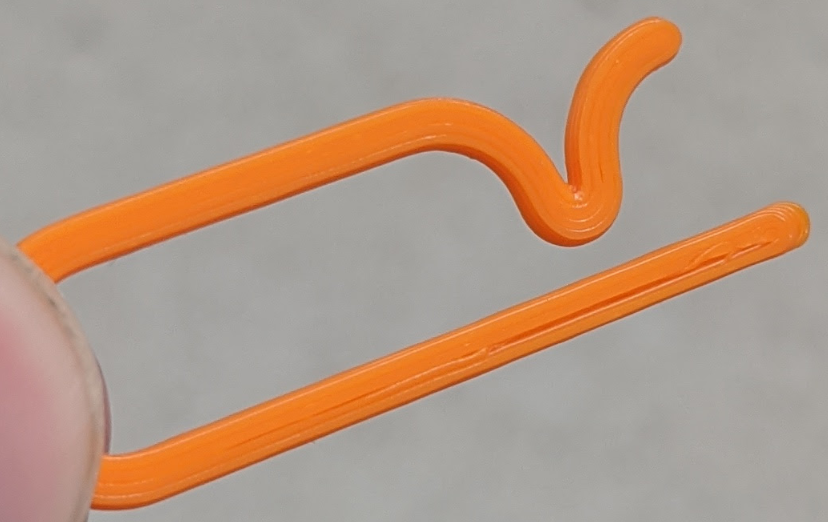

Pics to explain. This is the base one of those small pieces I mentioned that loses adhesion. Printed at 0.2mm QUALITY and Z of -1.00mm

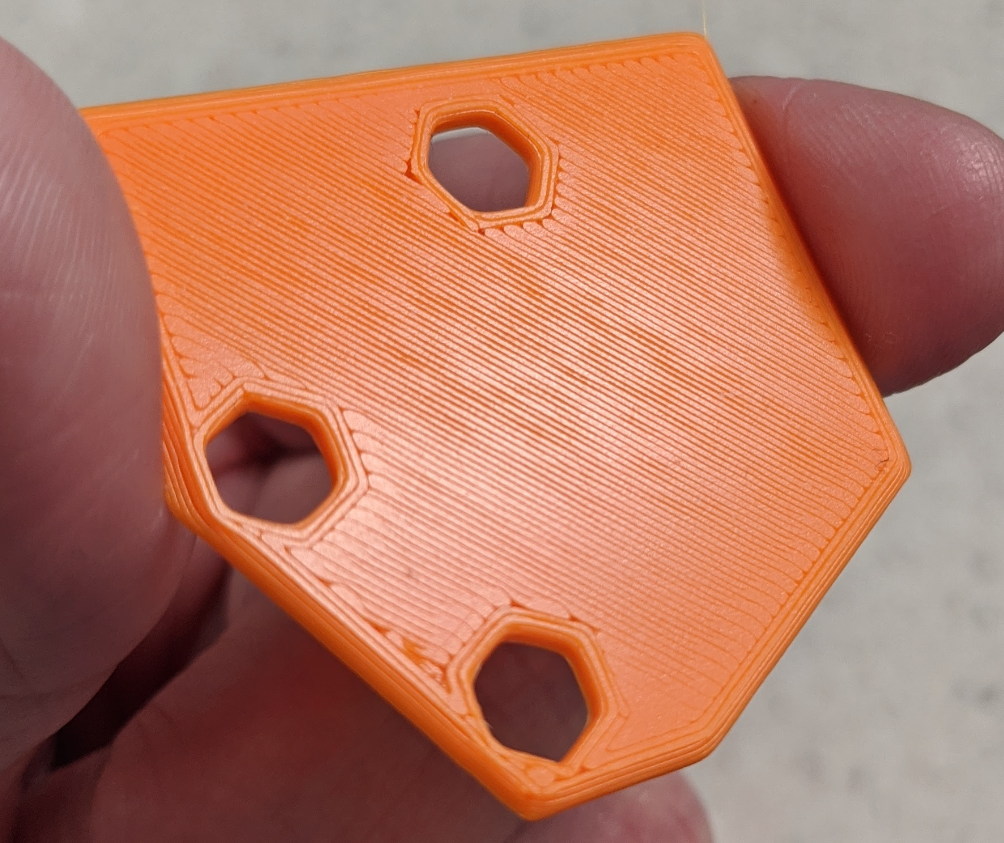

These larger parts were part of the same print job. This is the base.

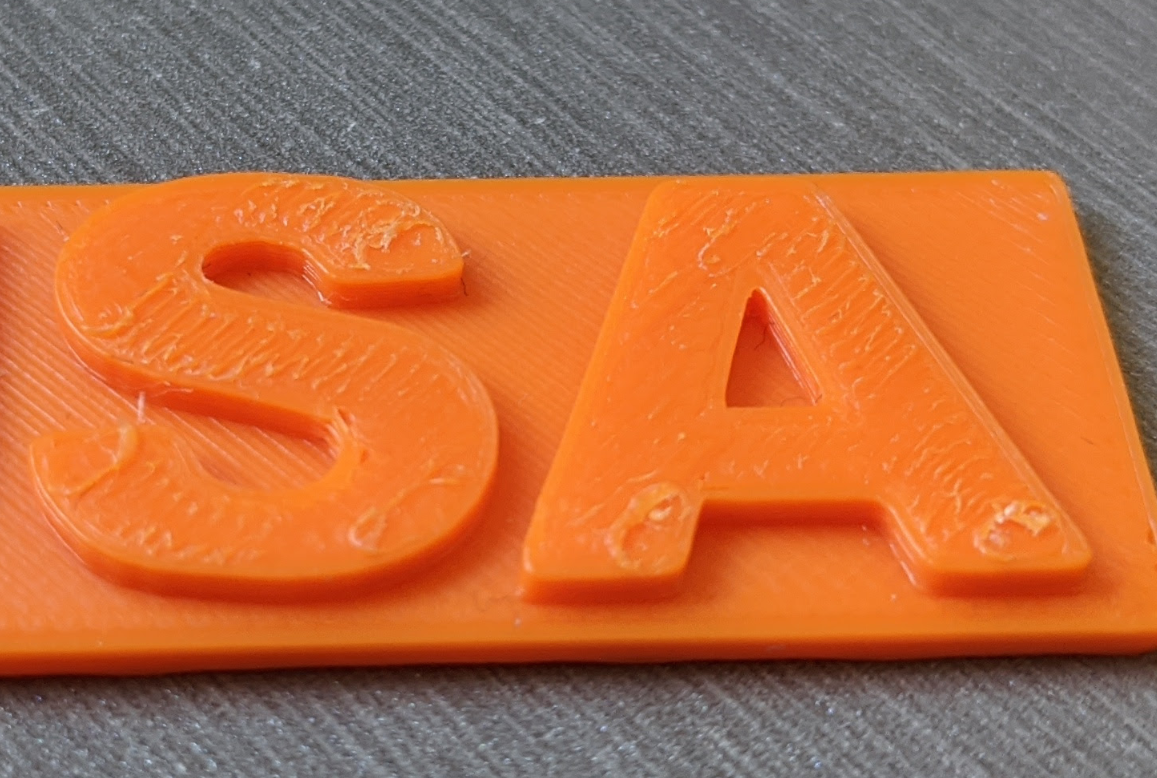

And this is the (unfinished) top of the same part

And finally, here is the issue with the top layer. 0.2mm I think, and Z is at -0.950mm for this one. In this pic you can see on the base plate that the larger surface is fine, but the smaller areas are inconsistent and pretty messy.

Cheers,

Andrew

Best Answer by Peter M:

There should be 0 holes in the first layer, in your first pictures there are holes.

Most important for 3d printing is:

1. Clean bed, this so parts do not get loose from bed, the parts will stick the best.

2. First layer should be 100%, is also because of better sticking to the bed, and smooth under lower layer, and if to high you will have to much filament higher up in the print.

Search for a good first layer print test model, with a few squares spread over the build plate. Adjust, test, check if all is OK over the whole bed.

In settings of printer use 7x7 calibration.

make a good first layer picture si we can see if it is OK.

In general I work like this:

A new sheet will stick less then a used one.

PLA sticks more difficult on a powder coated sheet. Is still possible settings need to be more preciese.

This how I work on a pei sheet(there are always exceptions):

Most important to 3d printing is:

1. 3d print will never be like start and i have the print, there will always be problems!!!!!!

2. A clean sheet, use dish soap, then you can print on it. A few prints you can use alcohol, then again dish soap,

big flat models and models with small footprint on sheet- use glue stick(and not every glue stick is the same,

use one that makes a thin layer), and big flat models and small footprint, use a big brim attach to model so footprint is bigger.

Petg sticks to much on the pei sheet, use window cleaner, this leaves a layer on the bed, so it does not stick to much.

3. To get it stick very good, a 100% first layer is very important, see youtube for movie on this.

Every new print watch the first layer, and look if it is 100%, this will also prevent a big ball of filament on your nozzle wen model let loose during printing.

Extra: (normally not needed).

First layer, print hotter.

First layer slower.

Bed more heat.

Most problems are first layer to get this 100%, and bed not clean.

Bad filament is possible, or filament with water inside.

Move extruder to the top and extrude filament, it should go straight down(if not, nozzle possible blocked),

it should be thick enough(if not, nozzle possible blocked, or partial blocked), (do a cold pull),

if Bubbling during extrusion then it has to much water inside.

Check after the first layer is ready, then you see if it sticking enough, and not releasing and sticking to the nozzle.

If you see white spots like a bubble on the bed, then filament is releasing from bed.

Also no gabs between lines should be visible.

Use 7x7 calibration for first layer, see settings in the printer.

Search for " 3D printer first layer problem Calibration process" on youtube, movie on first layer calibration, with a good zoom in.

RE: Need some help to fine tune for small parts

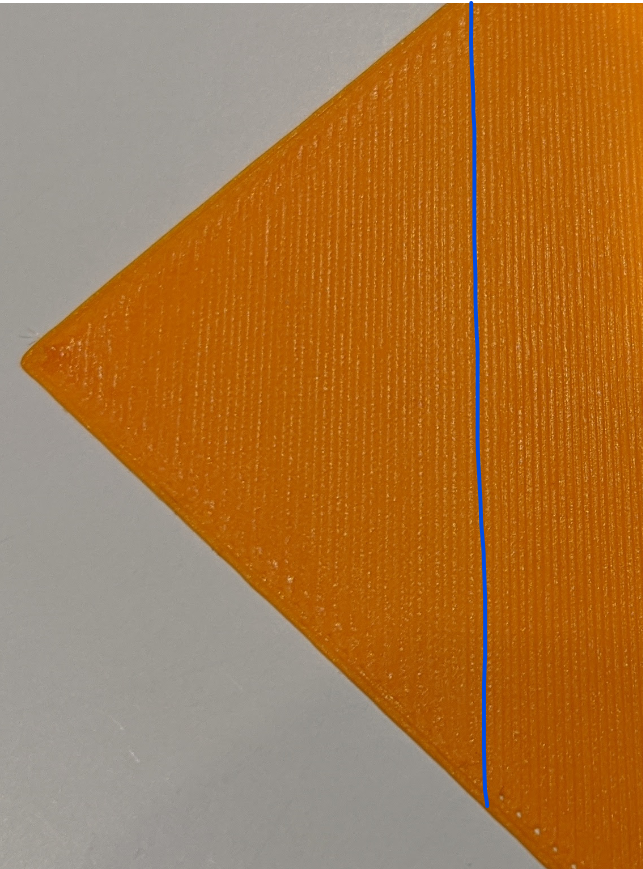

More info. I did a better first layer test but still had issue when I tried to print. The first pic shows the settings I decided on during the test that I would use in the print job. To the left of the blue line, which is PLA 215/60 @ -1.025 Please click the pics, they'v been squished and makes base layer look worse than it is. (Failed print pics to follow)

The circled item was printed first and looks perfect but things just got worse from there. What gives?

RE: Need some help to fine tune for small parts

There should be 0 holes in the first layer, in your first pictures there are holes.

Most important for 3d printing is:

1. Clean bed, this so parts do not get loose from bed, the parts will stick the best.

2. First layer should be 100%, is also because of better sticking to the bed, and smooth under lower layer, and if to high you will have to much filament higher up in the print.

Search for a good first layer print test model, with a few squares spread over the build plate. Adjust, test, check if all is OK over the whole bed.

In settings of printer use 7x7 calibration.

make a good first layer picture si we can see if it is OK.

In general I work like this:

A new sheet will stick less then a used one.

PLA sticks more difficult on a powder coated sheet. Is still possible settings need to be more preciese.

This how I work on a pei sheet(there are always exceptions):

Most important to 3d printing is:

1. 3d print will never be like start and i have the print, there will always be problems!!!!!!

2. A clean sheet, use dish soap, then you can print on it. A few prints you can use alcohol, then again dish soap,

big flat models and models with small footprint on sheet- use glue stick(and not every glue stick is the same,

use one that makes a thin layer), and big flat models and small footprint, use a big brim attach to model so footprint is bigger.

Petg sticks to much on the pei sheet, use window cleaner, this leaves a layer on the bed, so it does not stick to much.

3. To get it stick very good, a 100% first layer is very important, see youtube for movie on this.

Every new print watch the first layer, and look if it is 100%, this will also prevent a big ball of filament on your nozzle wen model let loose during printing.

Extra: (normally not needed).

First layer, print hotter.

First layer slower.

Bed more heat.

Most problems are first layer to get this 100%, and bed not clean.

Bad filament is possible, or filament with water inside.

Move extruder to the top and extrude filament, it should go straight down(if not, nozzle possible blocked),

it should be thick enough(if not, nozzle possible blocked, or partial blocked), (do a cold pull),

if Bubbling during extrusion then it has to much water inside.

Check after the first layer is ready, then you see if it sticking enough, and not releasing and sticking to the nozzle.

If you see white spots like a bubble on the bed, then filament is releasing from bed.

Also no gabs between lines should be visible.

Use 7x7 calibration for first layer, see settings in the printer.

Search for " 3D printer first layer problem Calibration process" on youtube, movie on first layer calibration, with a good zoom in.

RE: Need some help to fine tune for small parts

If adjusting fails because of not clean etc, you will get in the future a big ball of filament on the nozzle, which is difficult to remove.

Small parts use glue stick,

small parts use a brim attach to model, 6 or 8 lines.

Big flat parts use glue stick.

Petg use window cleaner, this sticks to much, and will damage your pei sheet.

RE: Need some help to fine tune for small parts

Don't try to fix adhesion issues with increasing your filament extrusion multiplier! They are 2 different things. If you crank up the extrusion multiplier, it will be in effect for the ENTIRE PRINT and likely create vertical wall and surface issues as well as making support impossible to remove. Leave extrusion multiplier at 1 (or default) for any Live-Z adjustments.

You can increase your 1st layer extrusion widths (Print Settings->Advanced->Extrusion width->First layer) to help with adhesion. This is most useful with smaller nozzle sizes.

I'm going to give you the full info dump for new users on these issues...

-

A dirty PEI print surface. Even if you don't think this is the cause, it's always a good idea to make sure your PEI surface is clean before trying any other fixes. If it's a smooth PEI sheet, take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails , and another dunk when acetone fails. Worst-case, use a 3M 7445 ScotchBrite pad or equivalent on smooth PEI to give it a very light buff, but only infrequently. If you've got a textured powder-coated PEI print surface, the official instructions are to use 91%+ isopropyl alcohol on it only. Rumors persist that some tribes deep in the jungle have had good luck getting started with these sheets by giving them a wipe with 100% acetone and a dunk with Dawn. Either way, there's no real warranty on these sheets. YMMV.

-

If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the on-board routine and much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers. You should not be able to peel the lines apart after printing, but the top should be regular.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Need some help to fine tune for small parts

@peter-m26 and @bobstro

After my initial post, I did what you both said after reading some other posts.

- I had cleaned the PEI sheet previously with dish soap but only half heartedly. This time I got serious, cleaned the crap out it and was extra cautious to avoid touching it - also no IPA actually.

- Followed the vid in @peter-m26 post and you can see the results above. Ended up with (what I reckon is) a spot on base layer. See pic above

When I went to print those small parts again, there were still some anomalies in the first layer. But I just thought, "Ah, let it go for a bit". Anyway, I ended up with this. I've even did another print job after that of larger parts and frankly this thing is probably 95% dialled in for PLA now. I'm stunned with how good it's printing.

Thanks for your advice guys!

RE: Need some help to fine tune for small parts

Pics didn't come through, but glad it's working better for you. 3D printing seems to me to be a bit more like cooking than machining. A lot is based on experience and difficult to explain. Getting the bed cleaned properly is very tactile (I can feel a bit of increased drag as I scrub it once the grease is gone) and visual (I have developed a pretty good feel for how much to raise or lower Live-Z while the 1st layer prints). When things go awry, just try to understand why and you'll get the hang of it all very quickly. Have fun with it!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…