Need help with printing PETG

Hello all, I've been printing PLA for a little while (only a few weeks on a Prusa) and I'm happy with my results.

I've only just started with PETG and it's all gone wrong - I think I addressed the basics (re-slicing, different temps, glue stick*, raised the live z-height almost 0.1mm, etc).

But:

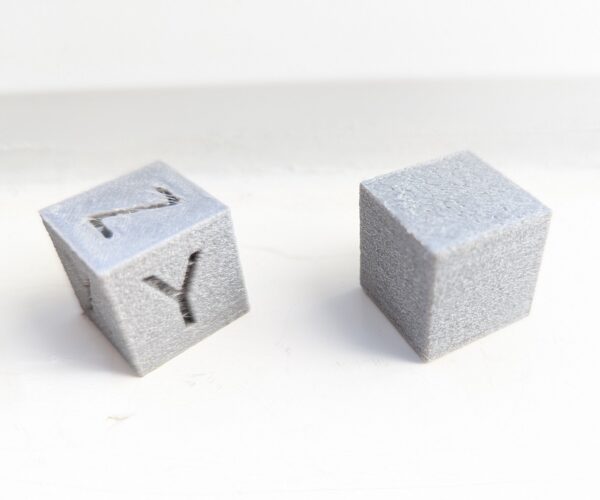

- Test prints are very fuzzy, but fuzzy skin is turned off in prusa slicer!!;

- Prints _really_ stick to the PEI sheet, including on top of glue stick prepared surface;

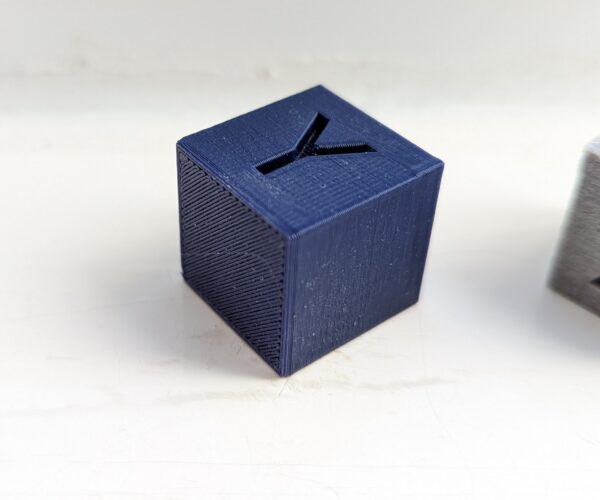

- Blue test cube is PLA - OK it's not perfect, but also far more usable than the PETG samples;

I am aware that the smooth PEI sheet is the worst to print PETG, I am tackling that. But that still doesn't explain the fuzziness of the test print.

I am using a brand new eSun PETG roll of filament, taken off the vacuum packed plastic bag yesterday, so should be low humidity when I started using it. Currently it's all inside a closed enclosure at 40% humidity.

Help?

Best Answer by zukpr:

My story is similar to yours. I'm new to 3D printing. I got an i3 MK3S+. PLA was printing fine, but my PETG prints all came out with excessive stringing and very coarse surfaces. The filament was "clear" but the prints were all milky white opaque. I also heard popping and sizzling while the printer was running.

I tried a variety of things, but I believe that several things were at play (in order from most clearly relevant to potentially less relevant):

- The filament was wet. Like you, it was new from a vacuum sealed bag, so I was assuming that it couldn't be wet yet, but I'm certain now that it was. I dried it out for about 12 hours in a SUNLU dry box.

- I'm convinced that part of the roll had absorbed moisture but the rest hadn't (or had absorbed less). At one point, half a print (the first layers) looked better (not great) but then the rest became milky white again. The sizzling also went away for a while after drying, came back again for a few minutes during a print, and then dissipated again.

- I reduced the temperature by 10 degrees Celsius

- I also played with retraction distance, retraction speed, and fan speed. I'm less confident that this helped.

My prints with the clear PETG have gone from a milky, stringy, rough opaque white to nice translucent, smooth surfaces. For the recent prints, if you hold a print to the light, you can see the infill patterns. For thin prints, they are what I'd expect from a clear PETG. And there is almost no stringing, even less than I was getting with my PLA rolls.

Good luck!

RE: Need help with printing PETG

Something is definitely off. Looks like the filament is damp. Even new rolls can contain excess moisture.

Try drying the filament and trying another test part.

Cheers

RE: Need help with printing PETG

Thanks - I considered that, dried the spool for a few hours in the oven and printed a temperature tower. It still crackles at 250C but seemed to print a lot better this time. I'll redo the cube shortly, hoping the enclosure at 40% humidity is enough to keep the spool dry enough.

Until the textured steel sheets arrive, I'm using the old ender print bed "mat" which is textured and that released the temperature tower quite nicely.

RE: Need help with printing PETG

My story is similar to yours. I'm new to 3D printing. I got an i3 MK3S+. PLA was printing fine, but my PETG prints all came out with excessive stringing and very coarse surfaces. The filament was "clear" but the prints were all milky white opaque. I also heard popping and sizzling while the printer was running.

I tried a variety of things, but I believe that several things were at play (in order from most clearly relevant to potentially less relevant):

- The filament was wet. Like you, it was new from a vacuum sealed bag, so I was assuming that it couldn't be wet yet, but I'm certain now that it was. I dried it out for about 12 hours in a SUNLU dry box.

- I'm convinced that part of the roll had absorbed moisture but the rest hadn't (or had absorbed less). At one point, half a print (the first layers) looked better (not great) but then the rest became milky white again. The sizzling also went away for a while after drying, came back again for a few minutes during a print, and then dissipated again.

- I reduced the temperature by 10 degrees Celsius

- I also played with retraction distance, retraction speed, and fan speed. I'm less confident that this helped.

My prints with the clear PETG have gone from a milky, stringy, rough opaque white to nice translucent, smooth surfaces. For the recent prints, if you hold a print to the light, you can see the infill patterns. For thin prints, they are what I'd expect from a clear PETG. And there is almost no stringing, even less than I was getting with my PLA rolls.

Good luck!

RE: Need help with printing PETG

Thank you, I did get the sizzling on the first prints, but not on the print tower at less than 250C, so the drying I improvised has helped.

RE: Need help with printing PETG

Inconsistent extrusion. At first glance it looks like the printer is making 'fuzzy' movements. If you are sure the mechanics are fine by testing it with PLA, then it must be the PETG filament causing the issue.

Though, I would verify the bondtech gears to be sure (check: grub screw, alignment, cleanliness and idler tension).

After that, it is most likely bad quality filament. I would try a roll of genuine Prusament and see if it goes away. I tried a few Chinese spools so far and I was not impressed. Bad quality control will produce variable product properties and you as the user will be chasing your tail to get consistent print quality.

RE: Need help with printing PETG

Can you clarify whether you are printing in an enclosure, or if you are just storing your filament in an enclosure?

RE: Need help with printing PETG

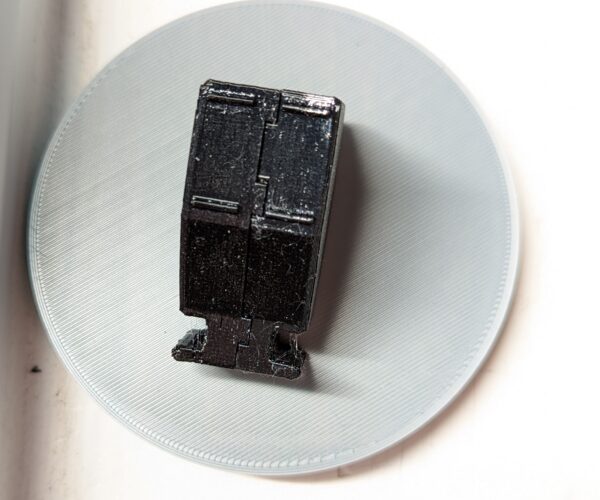

OK, after drying the filament in the oven, I got *much* better results. Still not there, but much closer to acceptable for me (picture looks worse than in real life, the fuzzyness is much reduced). I'm not 100% sure the filament has dried thoroughly, so I bought a dryer box and will be leaving it there for a while longer.

Notice on the temperature tower that quality improved as temperature decreased, which I was a bit surprised about. (you may spot some of the bridges are broken but that wasn't because of the print, I broke them accidentally). Also, the temperature tower was incorrectly sliced, whereby the bottom layer was printed at 240C rather than 250C. The rest is correct.

The printer is inside an enclosure, but not a solid sealed one, it's the Creality tent with a few mods. The filament is on the printer in the default location, on the standard mount for the mk3s - so not in an enclosure itself. The tent has 2x 350g dessicant bags, which are keeping humidity below 50% at all times.

The usual drying advice assumes the dampness comes from exposing the spoool to a humid atmosphere in your workshop so the outer layers are affected much more than the inner ones. A relatively short drying time deals with the outer layers preferentially...

but if the whole spool has become damp during long storage (maybe in a damp warehouse back in the supply chain) then you will have to dry for much longer, perhaps repeatedly, to rescue it.

Cheerio,

RE: Need help with printing PETG

The printer is inside an enclosure, but not a solid sealed one, it's the Creality tent with a few mods. The filament is on the printer in the default location, on the standard mount for the mk3s - so not in an enclosure itself. The tent has 2x 350g dessicant bags, which are keeping humidity below 50% at all times.

As I understand things, it is generally considered undesirable to print PETG in any enclosure at all. Most of what I have printed has been PETG and I have never used my enclosure for that, only for ASA. Maybe in addition to drying the filament more, lose the enclosure and see how that goes.

RE: Need help with printing PETG

I've had great results printing PETg in the enclosure. No stringing or any other issues.

RE: Need help with printing PETG

Good to know I was mistaken, thanks.

RE: Need help with printing PETG

Your mileage may vary. There are many factors involved. I've found that the enclosure does not hurt PETg (or PLA) prints, but there may be things about your particular set-up that may give you different results.

RE: Need help with printing PETG

Regardless of possibly being a bad idea, I've got no option because the environment where the printer is at is dusty and cold, so I have to have it covered.

RE: Need help with printing PETG

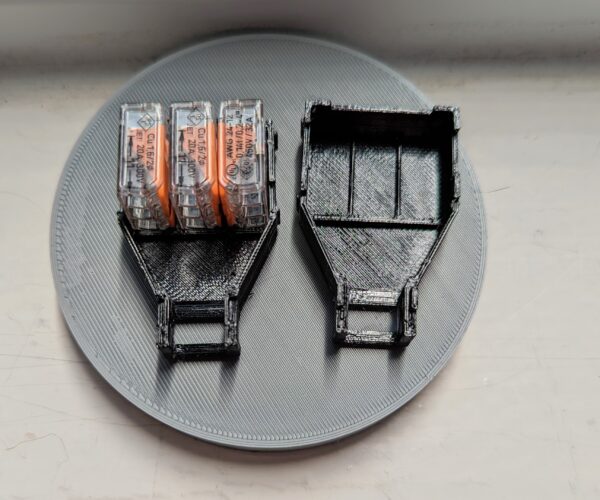

Just to close this thread off, I've dried the filament and made a few tweaks re: temperatures, etc, and got to a pretty acceptable result now. The part below is 1.25mm thick at the walls and the two halves locate together in place with 0.1mm tolerance in the x and y directions. The photos, again, look worse than the actual printed part, which took but 10s of cleaning to remove only a handful of strings.