My printed lines are slightly wavy

I'm having a strange issue that my printed lines are slightly wavy. It's making the appearance not completely smooth and straight. I recently changed the rods and bearings on my printer for new rods and bearings. Before this, it was having other issues, but not the wavy line issue. Originally my printer worked just fine, I should mention. So I know what the print quality should actually look like.

I tried Mesh Bed Leveling and it's almost perfect.

I spent hours doing Live Adjust Z to fix it. I moved the nozzle up until it had gaps and moved it down until it was too rough and found the perfect value where it was smooth. However, it still is printing slightly wavy lines.

I suspect that this might be related to the tension in my Y belt. My Y belt tension is 242, which is kind of low (tight). However, it seems very loose. I tried loosening it a little to raise the number (to 250), and it looked a little droopy. If I loosened it even more, the belt skipped. 242 is about as loose as I can go without it looking droopy. I didn't have this problem before, so I'm not sure what is wrong.

If you have any suggestions, I would really appreciate it.

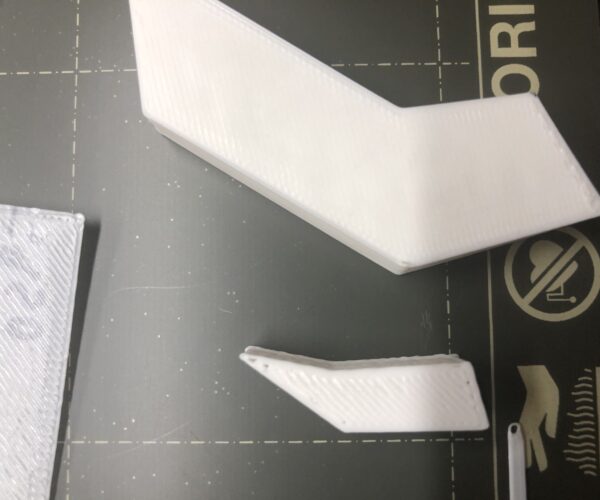

The image below shows a test print whistle. The top of it has slightly wavy lines. The sides are also not smooth, probably because of the wavy line layers.

This image below shows a difference between before and now. The top item is something I printed now that has slightly wavy lines. The bottom print is something I printed before I had all these printing issues and is fine.

RE: My printed lines are slightly wavy

The only suggestion I might make is to check your Y belt (and X belt) tension manually, rather than relying on the reported numbers.

When you gently squeeze the belt, it should resist the force somewhat, but not refuse to flex. Likewise, you should not be able to easily touch the two sides together with slight pressure.

TFM recommends adjusting it to sound like a bass guitar string when plucked. If you know, say, what the E string of a bass guitar feels and sounds like, you have an idea, but if you don't, it's not very helpful. 😉

That is my suggestion.

RE: My printed lines are slightly wavy

Thanks for the suggestion! I tightened it somewhat and tried test printing something, and it turned out much better but not quite all the way the same as before. So, I tried tightening it more so it would match the tightness of my X Axis (which seems like a perfect tightness), and the Belt Test refused to run giving me a check Y Axis length error. I’m now wondering if something is actually wrong with my Y Axis motor. The number represents how hard my motor is working, so maybe it’s working too hard for some other reason. But, maybe when I tightened the belt the full amount it put some more strain on my motor and the motor refused to work, causing the error.

RE: My printed lines are slightly wavy

The belt numbers as reported by the firmware are not representative of actual belt tension. It is a major flaw in the firmware. What those numbers report is a derivative of the motor driver currents. They tell you more about axis friction than belt tension.

The only way to know the belt tension is to measure it directly. Sound is one way, but the equations for finding the resonant frequency are insane. Deflection force is the easier way to measure. Basically - with a weight pulling down the belt - how far is it deflecting.

RE: My printed lines are slightly wavy

ps: botton line - pull down on the X belt with 7 ounces or 200 grams, the belt should deflect 15/64ths inch. 200 grams on the Y belt should deflect 12/64ths. Close is usually good enough.

By the way - my firmware tension numbers are over 300, yet my belts are very tight. Why? My bearing friction is very low.