More a Slicr3 issue than an extruder problem ?

Hello,

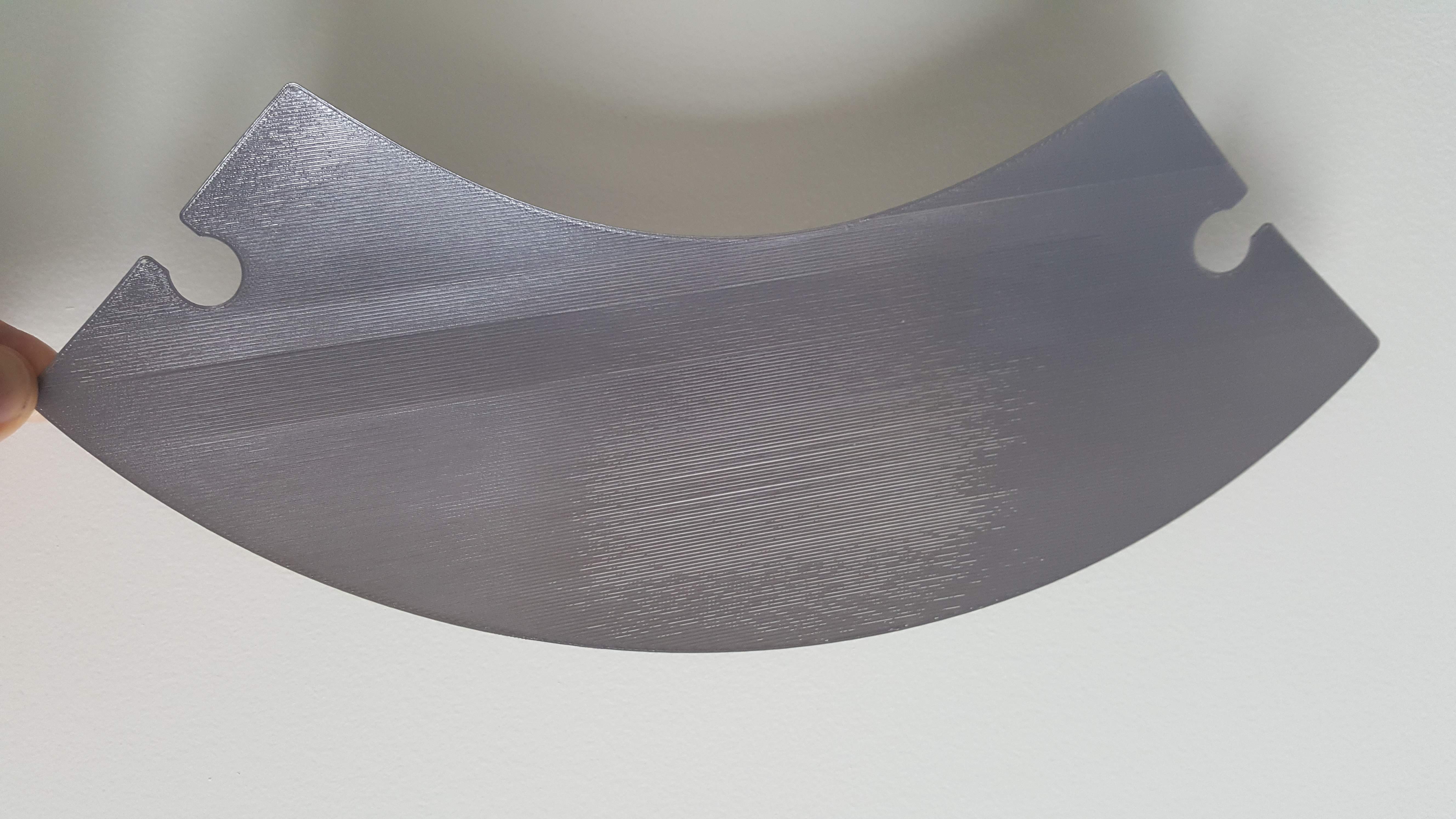

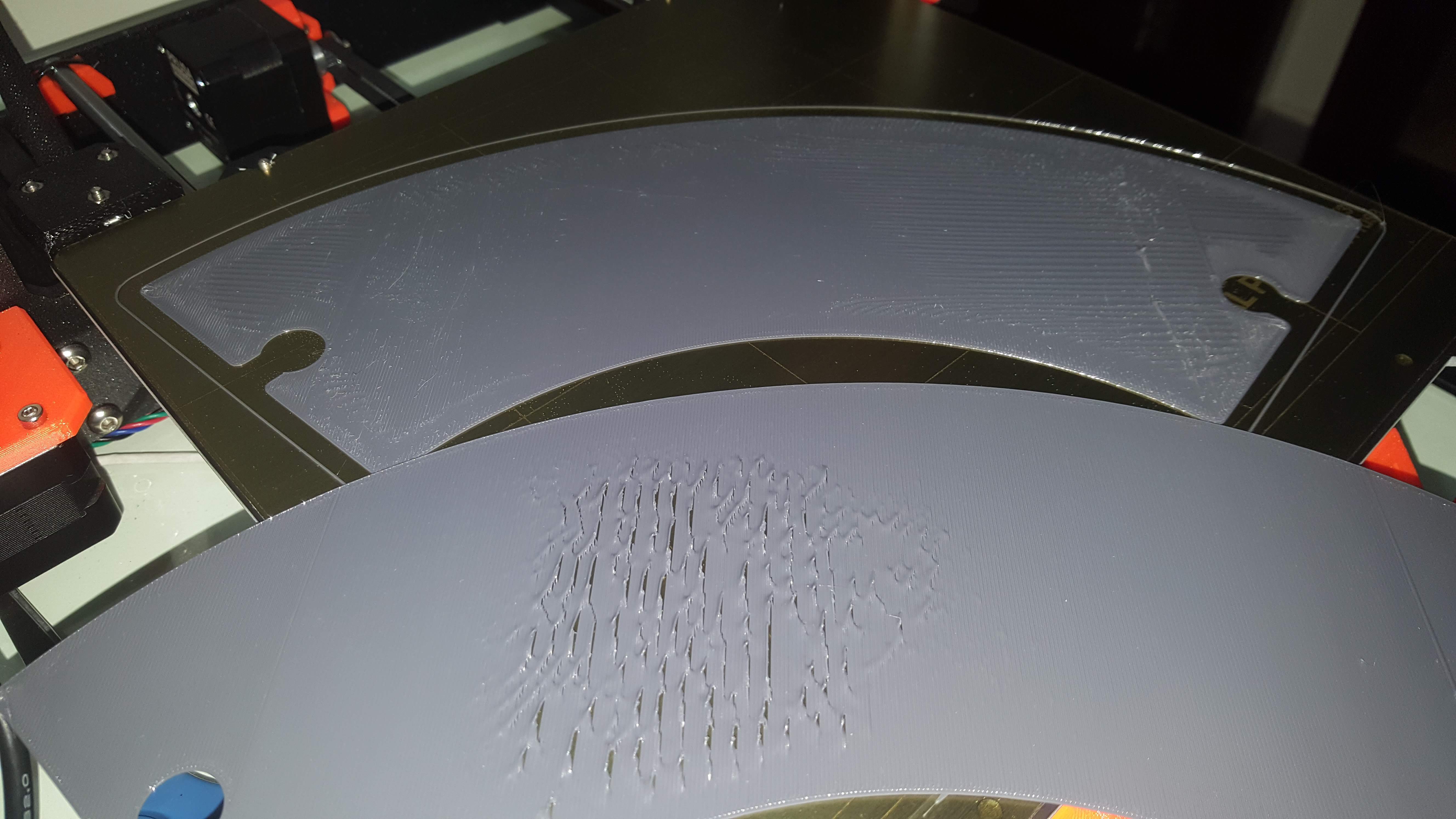

I am having some extrusion issue on the first layer of a large print (see pic 1).

I am using PETG from Das Filament for the first time on the MK3 with which I have been pretty happy on the MK2S for the same large prints.

This filament is well calibrated. I measured a diameter of 1,74mm to 1,75mm with a 0,01 accuracy caliper. I adjusted the extrusion factor with a factor 1,0215 after extruding two times 20cm.

As you can see, the reflection of the first layer is not consistent.

The shiny strips (2nd and 4th from the left) are smooth. But the non shiny strips (1st and 3rd from the left) are not smooth. The four strips are printed alternatively (Slicr3). The boundary of those 4 strips shows a little hump. I would say that the shiny strips are extruded enough but the non shiny strips are over extruded.

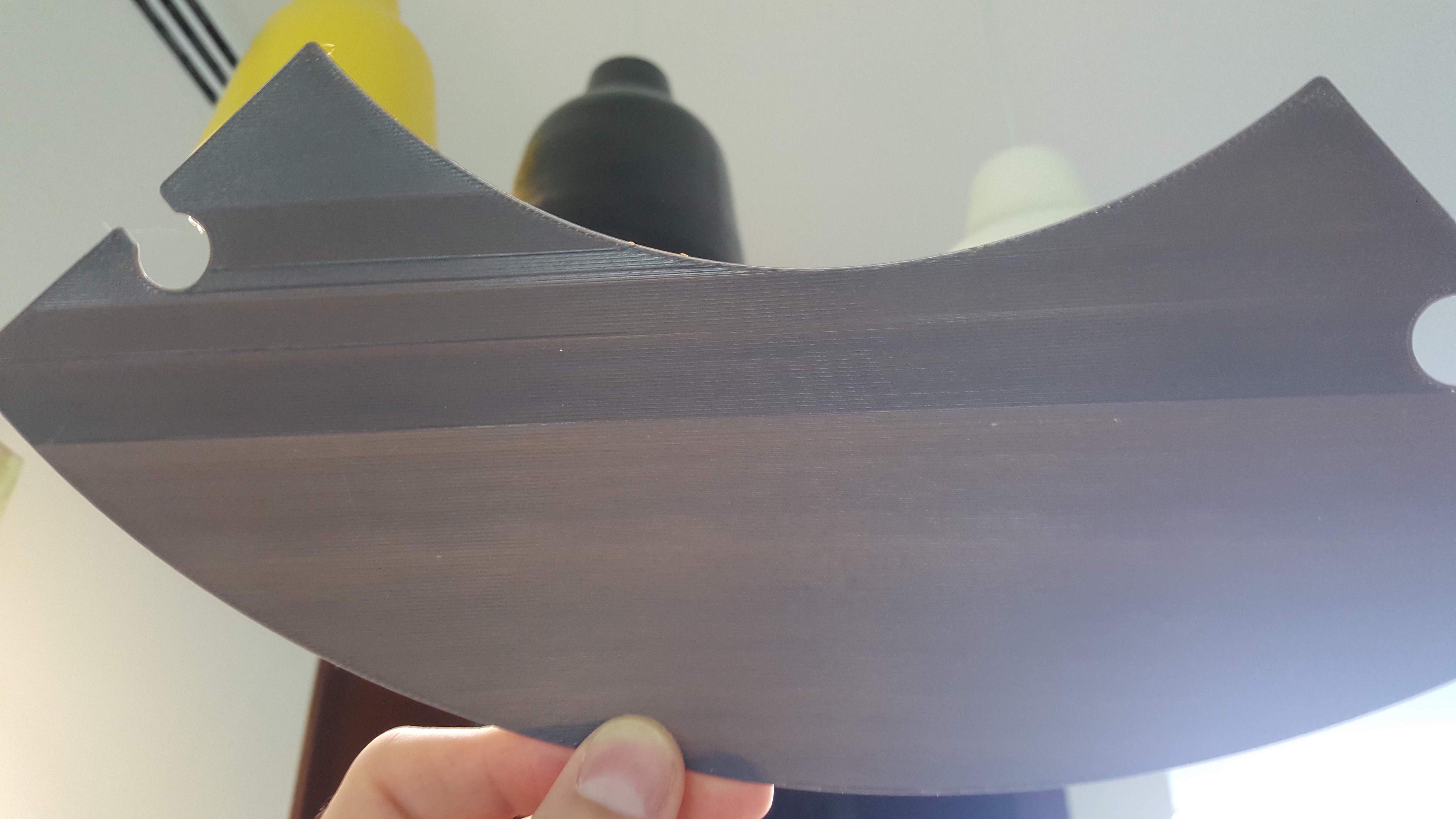

When the print completes I get some of that over extrusion that propagates to the top layer to turn into blobs with the pile up.

The fact that each strip is homogeneous in its area, I would say that it is a Slicr problem that for some reason extrude more or less between the four strips.

Anyone ?

Thanks.

Re: More a Slicr3 issue than an extruder problem ?

could try it with the part rotated around z about 30 degrees from where you have it - just change things up a bit and see what differences you get.

Re: More a Slicr3 issue than an extruder problem ?

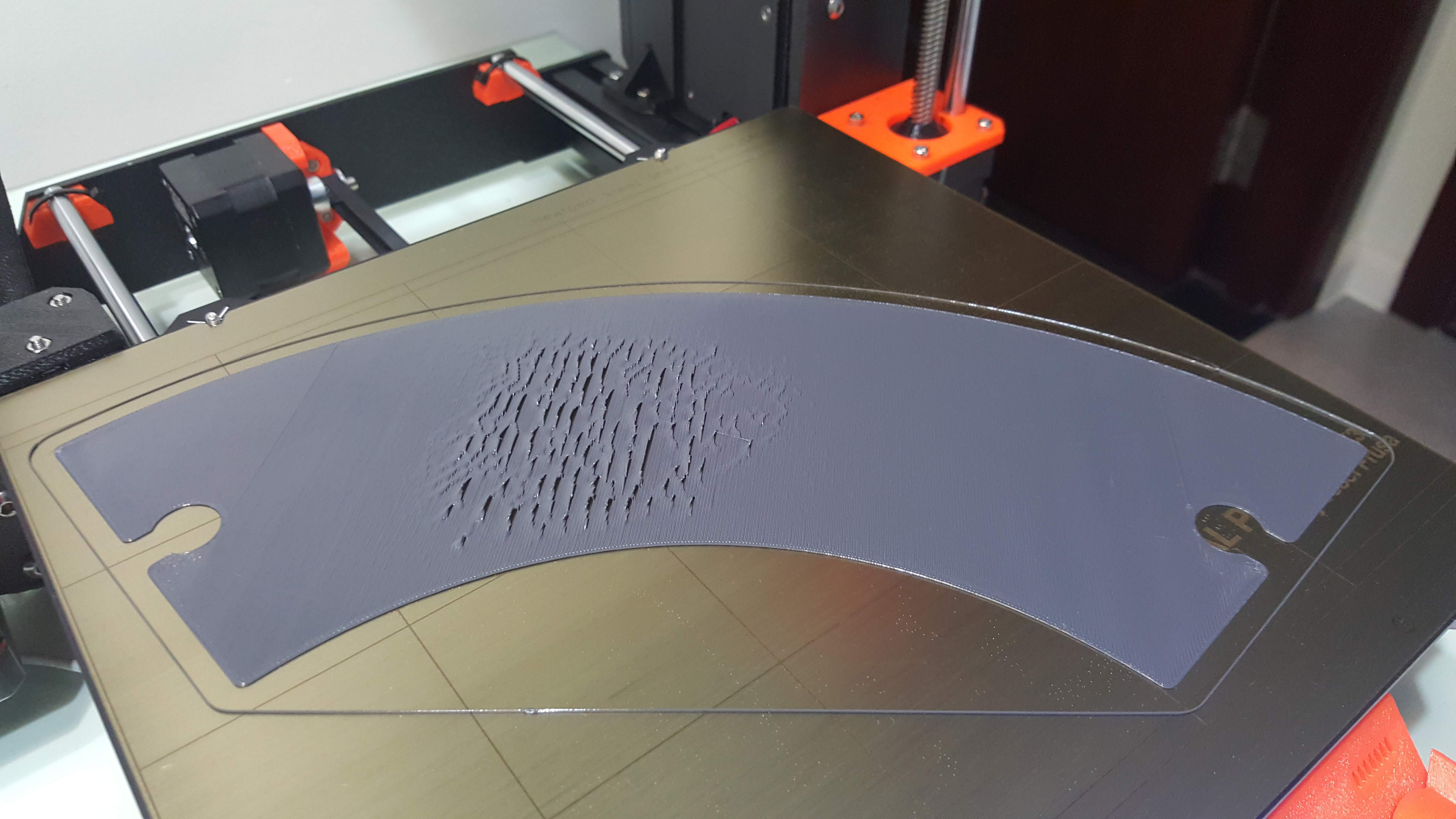

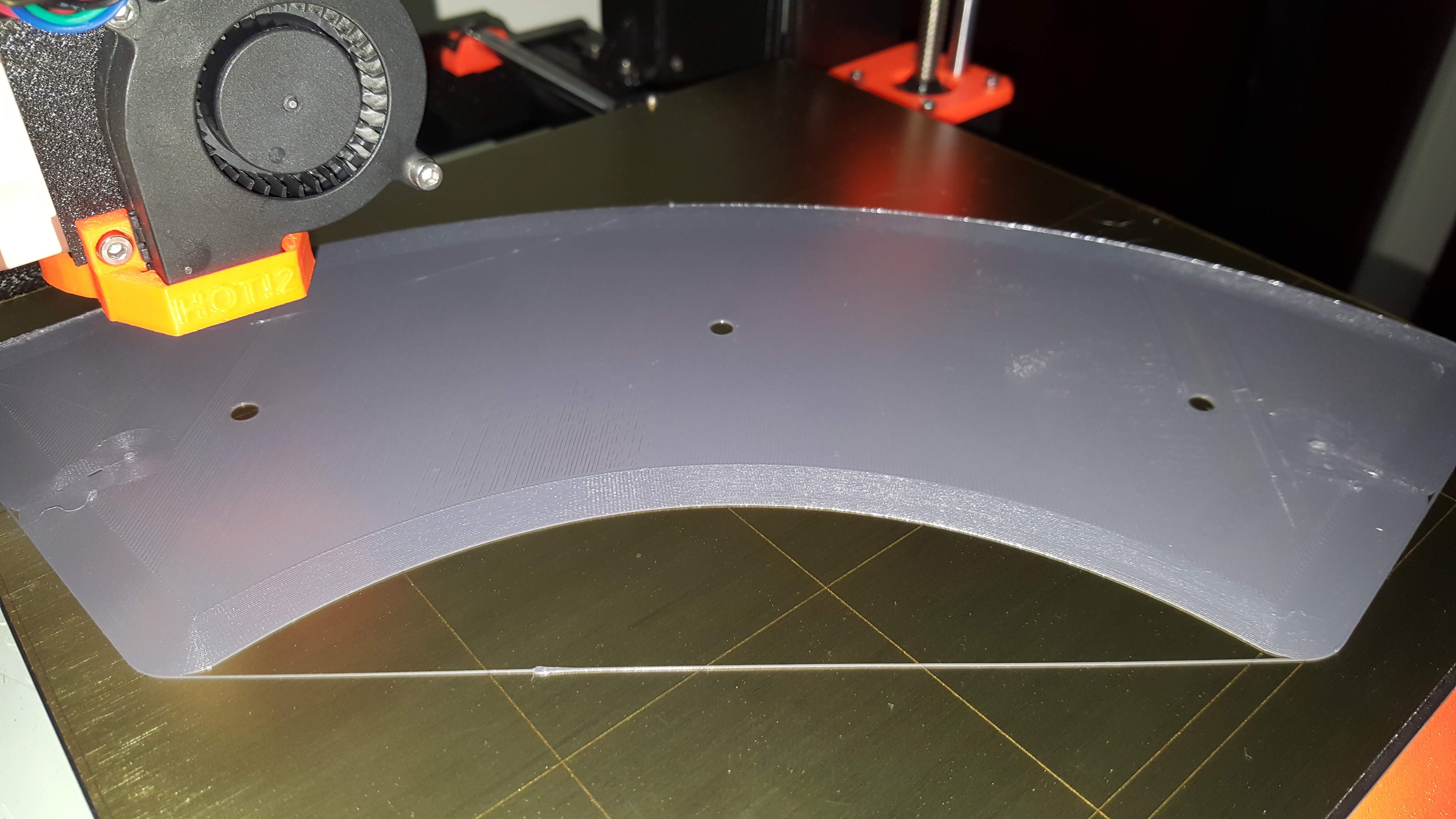

I decided to start over the print and the result is visible by transparency :

it looks a bit under extruded in the middle left position, many strings don't touch each other. The steel bed my be a little down in this area. I will have a look at the data of the mesh bed leveling.

Re: More a Slicr3 issue than an extruder problem ?

could try it with the part rotated around z about 30 degrees from where you have it - just change things up a bit and see what differences you get.

The part is as wide as the maximum printable size therefore I can rotate only 30° the part but I can mirror it that I will try.

Re: More a Slicr3 issue than an extruder problem ?

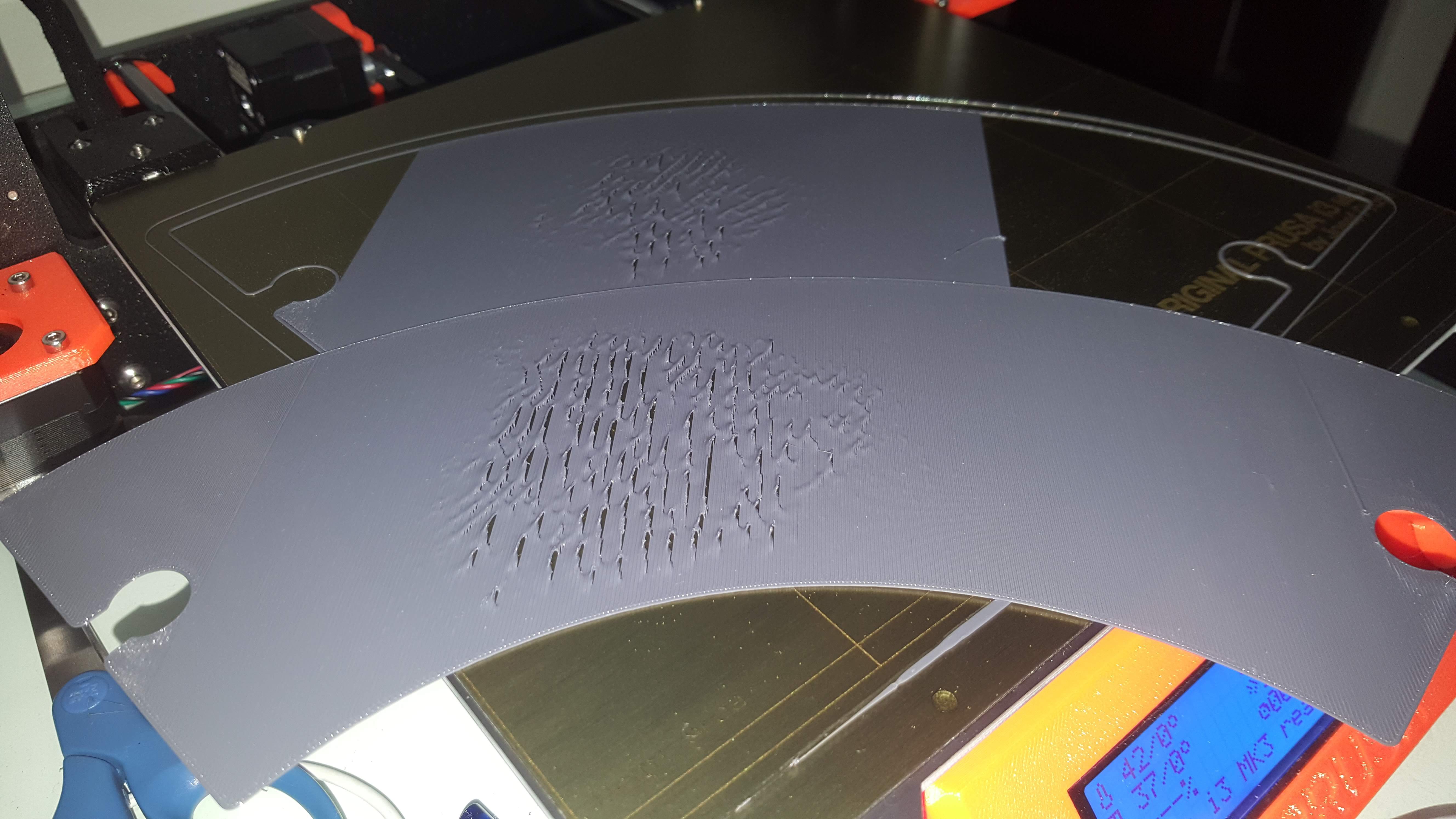

Here the unexpected result of mirroring the part or making it 90° to the left 😯

The stripping is seen on the left and lightly on the right where the last string was extruded where there is a bit of overlapping.

The big no-no is that kind of area where there is some bed adhesion problem that does not occur when the part is not mirrored.

Notice that Slicr prints this mirrored part with the same direction of strings : parallel to 45°deg line of (origin,x, axis, y axis).

This area matches the the area of the second pic of the post. It seems there is something over here.

Re: More a Slicr3 issue than an extruder problem ?

I had the same Problem with a 250mmx150mm Print.

The first "try´s" ended in Problems.

The first Layer looked like your last Picture.

I ended up with dish washing liqid an a slight rub with a "scrub-sponge".

That was all i had to do.

Although i thought it was really clean.

I do also use PETg from DasFilament.

Wer freundlich fragt bekommt auch eine freundliche Antwort.

nec aspera terrent

Re: More a Slicr3 issue than an extruder problem ?

I had the same Problem with a 250mmx150mm Print.

The first "try´s" ended in Problems.

The first Layer looked like your last Picture.

I ended up with dish washing liqid an a slight rub with a "scrub-sponge".

That was all i had to do.

Although i thought it was really clean.

I do also use PETg from DasFilament.

Good point kai.r3 😀

I cleaned thoroughly with non scratching pad (for non adhesive pan Spontex for Tefal) and some dish soap.

The no-no area have reduced so I will repeat the cleaning again insisting on the problematic spot hoping it will clean all for good.

Re: More a Slicr3 issue than an extruder problem ?

I thought I should flip over the plater to use the unused side.

And the result is :

Same punishment so the PEI is not the cause but I think nozzle height derived from the bed too much down in that area compared to the rest of the plater.

While It is set fine for PLA but it is not apparently for PETG.

Re: More a Slicr3 issue than an extruder problem ?

Try slowing the print speed down and altering the temperature up/down. You may also want to look at the extrusion width. I have slowly increased some of mine to get the extruded filament to give a flatter and more joined layer.

Re: More a Slicr3 issue than an extruder problem ?

My PLA Z offset is -0.442.

For this PETG, I adjusted up to -0.700 to get a adequate layer height for the skirt and the let go the print :

The no-no area is now fine but all the rest is now crappy over squished.

I struggled like never to remove those over squished area 😳 whereas I got no problem to remove the PETG part with the PLA Z offset.

There is definitely a locally bed level problem and my PLA Z offset is the good one even for that PETG.

Re: More a Slicr3 issue than an extruder problem ?

The only way to realy check for a bed level probem would be to fit a dial gauge to the x axis and move the bed/extruder keeping the Z height set. you will then see the alteration in the dial gauge reading. I am not sure how far the auto bed mesh leveling will compensate. someone should know.

Just some info for you. I set up a printer profile for each filament type i.e. PLA, PETG etc. In the profile i use the Z offset to alter any differerence that is needed in the first layer Z height. So i do a calibration for PLA then any other filament i use the live offset to find the good layer height new filament and the difference between the two is used as the Z offset in the printer profile. It save altering the first layer height if your having to switch between filament types.

Re: More a Slicr3 issue than an extruder problem ?

I eventually solved the problem.

As suggested by robin.a, I made a bracket to hold a cheap dial indicator. The measures were quite repeatable despite some drift of the readings due I think to the indicator not liking to probe so many points.

And the outcome was that the bed is flat within +/-0,1 mm ...

So I decided to use the hyperfine bed leveling firmware found here https://shop.prusa3d.com/forum/-f6/hyperfine-bed-leveling--t4330-s110.html#p41311 .

And the results are outstanding 😀

I have to thank warmly the contributors to this improvement : PJR JeffJordan waldemar.g