MK3S+ Kit: My biggest regreat. Please, I need help before contacting support to see wtf are my options

To understand my frustration, I bought this printer to replace my Ender3-V2 because I was not happy with little things, silly me.

I have had this printer for a week and I just cannot use it. I cannot make a $1.2k works like a $300 did

I took 2 days to assemble this printer following dot by dot and here we are.

16h printing below, turned into what looks like a $100 3D printer model

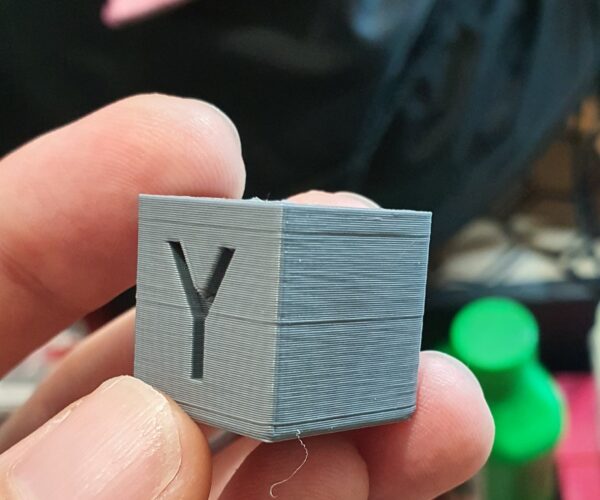

This is the quality I am used to.

Look at these lines man.

Yes, the silver colour does show more imperfections than any other colour. But those missing lines seem to have the exact same height and they are not right.

Owl printer few minutes ago

Look at those lines

I've asked for help on Reddit, biggest mistake, I was eaten alive for being unhappy with a Prusa printer.

On Discord group, some legends tried to help me and I managed to improve things a bit but not totally.

- This printer makes a lot of noise and vibrations. Even moving it from its wood desktop to the floor. I've noticed that a bunch of screws got loose perhaps because of the vibrations. I am looking into some 3D feet to remove the vibrations.

- Last night I disassembled the whole bed, Y is quieter now, a bit

- Ghosting: First time having such a problem. It seems to be related to the belt which I have tried to find the right tension but right now I just wanna the print to ............ print! I found a better X and Y belt tensioner but I need to solve these lines issues first. The last belt check was X=250 and Y=260

- Those missing lines are on Z. This printer is dual Z and I've no idea where to look at

- Calibration didn't fail, I did PID calibration, all calibration I could find and got nowhere, these inconsistencies are still happening

- To make things worse, the books said to don't lubricate the bearings and that was the worst idea. I did add lube to the rods but it is not the same as within the bearings.

- The filament spool keeps moving around, I can hear from the living room when it shocks against its support, it is that loud while holding a brand new 1kg roll. I am looking into adding my Sunlu dryer there instead. I believe those vibrations are also helping to screw things up.

For what it is worth, I am printing a scrapper now. Since it is thinner than the first missing line. It is looking fine so far.

Please, please, please, if you are gonna say "Prusa is Prusa, works out the box and I did a sh1t job", save it. I've had enough.

I hope someone WILLING TO HELP could help me somehow. I don't know what else to do, I don't wanna mess around as I don't have the Ender to print spare parts and so on.

Thank you

I read blog a long time ago when I bought MK3. Maybe similar with your "issue" - https://help.prusa3d.com/en/article/the-benchy-hull-line_124745/

RE: MK3S+ Kit: My biggest regreat. Please, I need help before contacting support to see wtf are my options

There appears to be some kind of a mechanical issue.

You said 'screws loose' and that would definitely be related.

Be sure all screws and fittings are tight. They should not become loose with operation. If there's enough vibration to shake screws loose, something is definitely wrong and needs to be looked into.

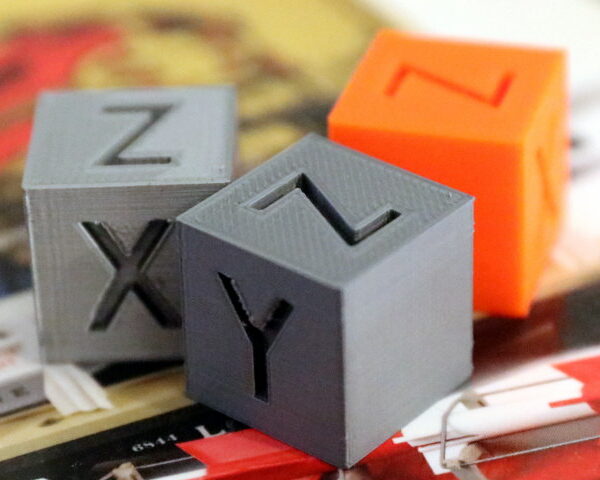

The vertical surfaces on the calibration cubes should be very smooth.

I would contact support and see what they say.

Focus on the getting calibration right before printing toys

Use your old printer to print the toys while you tune the new one. There are too many things at once to get your toy correct on the first print.

I'm with JSW - red flags in your post = "screws coming loose". Also "I did not lube the bearings" - ouch. Let's get that taken care of before you get in deep. Disassemble the X and the Y and take out the linear bearings (glad you did Z because that is the hardest set to change). Use the lube tool that came with the printer (you'll need a few more tubes of lube). One set of 6 will use the whole tube, and as you squeeze grease into the bearings, a lot of that packing oil will come out. Don't do this over the print bed - it gets messy.

That repeated, height related line - that's the next thing to go after. Leave the toys aside, start with a calibration cube (20 x 20 should do it). Better yet, start only with patterns that come with the printer pre-sliced (known good) - which came with the SD card. That removes learning curve problems from the mix on how to use prusa slicer (for now).

What screws are coming loose - it could be a clue. Be very specific, as there are dozens of screws that could be coming loose, but the one that does is probably closest to the problem. With the exception of the X carriage back-plate and the clips on the Y axis bearings, no screws should have been "barely tight".

The vibrations are at a max right now because you a) are using linear bearings (I don't use them any more), and b) because you didn't pack them with grease. Let's go after your Z problem first.

Thanks guys

Hi guys, I got somewhere after almost a week.

Resuming you guys feedback altogether:

- Bearing: Yes, the book does say that the bearings are ready to use and the lube is for maintenance only. Prusa Discord help channel mentioned to me that this part is wrong and you need to lube the bearings

- Vibrations/Noise: One of the loudest noise was coming from the single bearing on the Y axis. The rod was not smooth at all but very stop-go, stop-go. The other 2 bearings were smooth as they should. I added lube to the single one and less noise and Y axis smoother

- Loose screw: Because the system was generating vibrations asf, I noticed the screws on the extruder's back somewhat loose. Someone mentioned that a week after using the printer, he noticed loose screws. It kinda makes sense, system generating too much vibrations will create problems. X axis got more silence after that

- Extruder filament pressure screw: Or whatever it is called. While in contact with support, I managed to print a 10/10 PETG xyz cube without any missing lines. Support mentioned that the screw was a little too tight for PLA. I know, I have more questions than answers really. It appears that 2 extra turn I did, messed everything. I still don't get it but never mind.

- Next: I've been trying to get PETG right for days and only now things seem to be fucking working. I'm printing spare parts before disassembling anything. My Ender is gone so I've no backup and the last thing I need is broken parts. I'm also printing a better X and Y parts to remove ghosting. Ghosting is new to me, I never had this issue before and the stock X and Y belt tensioner is kinda hard to deal with.

For now I'm just happy that PETG seems to be printing but not before spending half day with failures.

I'll check the bloody extruder screw tomorrow morning. I'll just take it easy now, man, I've dealing with this frustrating for days.

Anyways

Only screws that should be looser are the ones on the extruder back - X carriage holder

Don't over-tighten the X carriage holder screws or you'll start getting X drift during prints or worse. My bottom screws are best when almost falling out. The top ones should only be tight enough to get the play out of the upper bearing. You do not want to squeeze those bearings.

RE: MK3S+ Kit: My biggest regreat. Please, I need help before contacting support to see wtf are my options

I'll just take it easy now, man, I've dealing with this frustrating for days.

Anyways

I feel you... When I first got MK3 - I struggled with it and it took me, maybe, 2 weeks to get it "perfect." Then I bought a new MK3S after I had problem with MK3 (upgraded to S) when I installed MMU2. I assembled MK3S and it was perfect right off bat.

The more you learn about MK3S+, the better you get with it. So, you'll be fine. 👍

Hi guys, I got somewhere after almost a week.

Resuming you guys feedback altogether:

- Bearing: Yes, the book does say that the bearings are ready to use and the lube is for maintenance only. Prusa Discord help channel mentioned to me that this part is wrong and you need to lube the bearings

I really wish that Prusa would clarify this !!

The Party Line is to use the lube that's on the bearings and do not replace/add. I interpret this to mean that Prusa thinks that whatever lube is in/on the bearings is more than adequate for the expected life of the machine.

However, a number of users have cited a note from the manufacturer of the bearings stating that the supplied lube is not intended as a permanent lube and to flush it out and replace it.

I followed the instructions when assembling and did not re-lube the bearings.

Every so often I put a drop of light synthetic machine oil on the rods and exercise the axes, as per the Party Line.

Every so many so oftens I'll rub some Superlube on the rods.

The last time I checked, the total print time was 600-some days on my machine, and the bearings have not self-destructed. There's no discernible 'play' on any axis and the print quality has been consistently good.

I would also think that since Prusa uses hundreds (thousands?) of these in their 'farm', running almost 24*7, they would certainly note any bearing failure and would adjust their instructions if the lubrication was really an issue.

Feedback

Hi guys,

Just a quick feedback on this:

- I have been trying to print PETG for 2 days without much success. Screw holes get all messed up in the nozzle. I change the temps instead of using Prusa profile, I am getting somewhere but not without using a thick brim to hold the model down. I have tried everything, hot water with soap, Windex, ISA, glue, you name it. The model lifts the bed like xyz cube lift from the bed and gets stuck on the nozzle making a mess.

- I have slowed everything down as much as I think it is worth, the first layer is set to 12.5mm/s

- PETG sheet: The sheet I am used to printing PETG and TPU, is way more "powder coated", much rougher. PETG on it was like 100% success. On this Prusa sheet, it is way smoother. I believe I found a similar sheet with Prusa size but I need to get these parts printed now so this will need to wait.

- I haven't tried PLA again, I need this new X and Y-axis support in PETG to replace the stock ones and get rid of the ghosting. They provide a better belt calibration.

These are the upgrades I am doing:

Y-axis tensioner: https://www.prusaprinters.org/prints/57663-y-axis-belt-tensioner

X-axis tensioner: https://www.prusaprinters.org/prints/56241-x-axis-revision-with-belt-tensioner

Right now I praying to get these parts printed somehow, disassemble the whole X and Z to lube the bearings as they are supposed to and be able to calibrate the belts easier.

Hi guys, I got somewhere after almost a week.

Resuming you guys feedback altogether:

- Bearing: Yes, the book does say that the bearings are ready to use and the lube is for maintenance only. Prusa Discord help channel mentioned to me that this part is wrong and you need to lube the bearings

I really wish that Prusa would clarify this !!

I did notice difference day and night on my Y just by adding lube in the single bearing that was a little bit rough. It is way quieter now and has fewer vibrations.

I took 2 weeks off just to play around and get to my 3D project, these 2 weeks have been nothing more than being unable to print without dozens of failures.

At this right moment, I just hate myself.

I will update your guys within a day or so if I manage to get all the PETG models printed and replaced.

Thanks for everything.

Way too slow - PETG will be a total mess

Not sure why you are just trying random things instead of taking advice - but hey, it's a free internet. 12mm/s for PETG is going to be a total hairball, your nozzle will get all screwed up and your prints will fail. If you are really interested and ask why, I'll tell you. But you arent' in a listening mood, so I'll just leave the advice at "run default profiles for PETG with no changes and focus on your live Z."

I agree.

I've found very few cases where defaults will not produce good prints, with any filament.

Almost there

Not sure why you are just trying random things instead of taking advice - but hey, it's a free internet. 12mm/s for PETG is going to be a total hairball, your nozzle will get all screwed up and your prints will fail. If you are really interested and ask why, I'll tell you. But you arent' in a listening mood, so I'll just leave the advice at "run default profiles for PETG with no changes and focus on your live Z."

I am using the temps and speed I am used to using and having 100% success, but instead, I have been having 100% failures.

The basic rule I learned is to go slow during the first layer. I won't blame myself for the shit experience I have been having since day one. 80mm/s infill is madness.

I tried Prusa profile and it was not different, total hairball and my nozzle/base of hotend is all messed up with melted filament thanks to that.

I cleaned everything as better as I could with a wire brush. So why I started playing around with speed/temp. I was getting nowhere anyways.

Better late than never, It seems like I am getting somewhere.

I upgraded my X-axis: https://drive.google.com/file/d/11D26OW7ZU9TAjzQ47SIi2ORkPxVUxXgR/view?usp=sharing

To calibrate the belt I just need to tight 2 screws: https://drive.google.com/file/d/1tty5_7DdYjMJA_a-8pFCE3b8GCZ5QbCf/view?usp=sharing

XYZ cube is already showing improvements. X has almost no more ghosting which is awesome. The little 4 holes is because my filament, I need to dry it, haven't used it for almost 2 weeks. I also need to lower the nozzle a little bit more: https://drive.google.com/file/d/1VDb6yFhF_yZg-mc-uAAAwZ2OuC9c5y8X/view?usp=sharing

Y is still the same, I already printed a replacement for it allowing an easier belt calibration. Y is still showing a line at the top, I have done another adjustment and will monitor: https://drive.google.com/file/d/1LRApswAYA9i3ftju1hKOLlY85q84TDAs/view?usp=sharing

I am happy that I am getting somewhere, finally, after 2 weeks wasted.

I am printing a 3DBenchy now, the writing was done slowly and without mess up, I was kinda surprised.

I will post a last update once the benchy is done but we are back in business, little details here in there. I will stick with PLA for now.

slow down

Not sure why you are just trying random things instead of taking advice - but hey, it's a free internet. 12mm/s for PETG is going to be a total hairball, your nozzle will get all screwed up and your prints will fail. If you are really interested and ask why, I'll tell you. But you arent' in a listening mood, so I'll just leave the advice at "run default profiles for PETG with no changes and focus on your live Z."

Listen to the guy above and he will help you.

Hi guys,

Just a quick feedback on this:

- I have been trying to print PETG for 2 days without much success. Screw holes get all messed up in the nozzle. I change the temps instead of using Prusa profile, I am getting somewhere but not without using a thick brim to hold the model down. I have tried everything, hot water with soap, Windex, ISA, glue, you name it. The model lifts the bed like xyz cube lift from the bed and gets stuck on the nozzle making a mess.

- I have slowed everything down as much as I think it is worth, the first layer is set to 12.5mm/s

- PETG sheet: The sheet I am used to printing PETG and TPU, is way more "powder coated", much rougher. PETG on it was like 100% success. On this Prusa sheet, it is way smoother. I believe I found a similar sheet with Prusa size but I need to get these parts printed now so this will need to wait.

- I haven't tried PLA again, I need this new X and Y-axis support in PETG to replace the stock ones and get rid of the ghosting. They provide a better belt calibration.

These are the upgrades I am doing:

Y-axis tensioner: https://www.prusaprinters.org/prints/57663-y-axis-belt-tensioner

X-axis tensioner: https://www.prusaprinters.org/prints/56241-x-axis-revision-with-belt-tensionerRight now I praying to get these parts printed somehow, disassemble the whole X and Z to lube the bearings as they are supposed to and be able to calibrate the belts easier.

Hi guys, I got somewhere after almost a week.

Resuming you guys feedback altogether:

- Bearing: Yes, the book does say that the bearings are ready to use and the lube is for maintenance only. Prusa Discord help channel mentioned to me that this part is wrong and you need to lube the bearings

I really wish that Prusa would clarify this !!

I did notice difference day and night on my Y just by adding lube in the single bearing that was a little bit rough. It is way quieter now and has fewer vibrations.

I took 2 weeks off just to play around and get to my 3D project, these 2 weeks have been nothing more than being unable to print without dozens of failures.

At this right moment, I just hate myself.

I will update your guys within a day or so if I manage to get all the PETG models printed and replaced.Thanks for everything.

You are making too many changes at once. If you throw ten red rubber balls at the wall with different glues on them and one sticks to it, how do you tell which one worked?

I recommend you slow your prints down.

--------------------

Chuck H

3D Printer Review Blog

End!

Listen to the guy above and he will help you

I have been listening to everybody and everything I hear is that "Prusa works out of the box and I did a shit 2 days assembling".

It is natural you get mad after spending AUD1.2k on a printer and ".... works out of the box..." is everything you hear.

Prusa community hates Ender community but you are more welcome there when you have problems than here.

Perhaps because there, we know that nothing is perfect, you receive what you paid for, your good experience might not be the same as somebody else and vice versa.

I've had a shit everything since day one here.

That is past now, my Ender is gone, this Prusa is everything I have now and I will make it work in one way or another.

The only thing I learned in the hard way, if you say one thing wrong about Prusa, you are toasted man.

I've been reading old posts, users problems, knowledge base, and learn from there instead. Avoid people telling me ".... works out of the box..."

I will dry the filament during the night.

Bottom: https://drive.google.com/file/d/1hH07V1JpXIK2k4uvZD2c5yfdZhSIm_ID/view?usp=sharing

Right: https://drive.google.com/file/d/1hCvjPlt7ACUwvIdxq_OPefffi3e63Y5t/view?usp=sharing

Left: https://drive.google.com/file/d/1h7KpUGHQU5OpNzXvA63k75Ryxo4_KCF_/view?usp=sharing

Back. The writing looks crappy, I hope to solve that with the Y belt upgrade: https://drive.google.com/file/d/1h5FlpFCVlGl1rf9wk8gWZcp1NH7kpdQ7/view?usp=sharing

I am happy with this result. Thanks for all the help.

RE: My three cents

"It is natural you get mad after spending AUD1.2k on a printer" It most certainly is but perhaps you should talk to Prusa support, it is part of the reason why an Ender is so inexpensive and a Mk3 most definitely isn't. You paid for unlimited support, why not use it. Log into the shop page and use the chat option (don't use email).

"Prusa community hates Ender community but you are more welcome there when you have problems than here." I don't think that's true, all I can say is that early on the learning curve I post some silly shit (and sadly still do) and nobody jumped on me.

I'm not a Prusa owner but I like this forum, so much better than manufactures who use facebook even though it's totally inappropriate for the task of a user forum.

Creality.

I absolutely love Creality. There terrible support and quality continues to drive users to Prusa.

"It is natural you get mad after spending AUD1.2k on a printer" It most certainly is but perhaps you should talk to Prusa support, it is part of the reason why an Ender is so inexpensive and a Mk3 most definitely isn't. You paid for unlimited support, why not use it. Log into the shop page and use the chat option (don't use email).

"Prusa community hates Ender community but you are more welcome there when you have problems than here." I don't think that's true, all I can say is that early on the learning curve I post some silly shit (and sadly still do) and nobody jumped on me.

I'm not a Prusa owner but I like this forum, so much better than manufactures who use facebook even though it's totally inappropriate for the task of a user forum.

--------------------

Chuck H

3D Printer Review Blog

I absolutely love Creality. There terrible support and quality continues to drive users to Prusa.

Back when I was shopping for a printer, the consensus among those I spoke to who had experience with Creality was that they were high-maintenance.

Yes

That is my point but much more eloquent.

I absolutely love Creality. There terrible support and quality continues to drive users to Prusa.

Back when I was shopping for a printer, the consensus among those I spoke to who had experience with Creality was that they were high-maintenance.

--------------------

Chuck H

3D Printer Review Blog

Not feeling the love

@ratolloko I guess you're not feeling the love. Wouldn't it make more sense to swallow the delivery and tax, get your money back and buy whatever the latest Ender is. This is still a great board both for nonPrusa and Prusa people, hope you hang around.

@ratolloko

Believe me, I can fully understand your frustration.. I think your expectations were just too high (regardless of paying high price).

Similar almost happened to me too (I have Prusa Mini+), but I realized and accepted the fact, that "works out of the box" doesn't exist in consumer 3D printer market -at least not in literary sense. Those who had "works out of the box" experience, were either lucky or experienced users who know on what they need to pay attention when assembling & adjusting.

Yes, even Prusa needs fine tinkering at beginning and once you accept that, you'll realize it's quite a solid long term machine -just give it a fair chance. Is it better or worse than other known brands? Neither -the answer depends on what you're looking for.

And about this forum.. I'd say it's similar to other forums. I would say members are patient and willing to help.. as long person who ask for help is willing to listen.

Open a beer and take deep breath.. soon you will realize got yourself a reliable machine 😍

[Mini+] [MK3S+BEAR]