Simple detail

I think your expectations were just too high

That was my biggest mistake really after reading "it works out of the box" here and there.

If you are new to 3D printing, you will love it since it is your first printer so you have no quality standards yet, no experience, you are learning.

But, if you already had a printer, know how basic things works, your quality standards is something else.

- Ghosting: Even parts from Prusa to assemble the printer shows ghosting. I never had such a problem before.

- PETG: To solve the above coz the belt stock tensioner sucks, I installed some custom parts that removed the X-axis ghostling like 99%. Waiting to apply the same on the Y-axis BUT....... it took me days to print the models as they were lifting from the bed. I had to add a very thick brim to keep the model from lifting.

- Textured sheet: I had to sand it down, that is correct, I had to sand a brand new sheet to increase the PETG adhesion. What the actual f !!!! I bought another sheet brand from the US to replace this "pretend I am a textured sheet"

- Noise: This printer makes more noise than a girl having an orgasm. I had to disassemble it to lube the bearings, things improved but still mehhh

If I knew my experience would have been this bad, I would have stayed with my Ender3 V2. Sure, endless bed levelling but I didn't know I was happy.

No maintenance or cheap if needed, no support but hey I contacted Prusa to inform that the Y rod holder cracked for non-normal reasons during the assemble "ohh you can easily print it". Sure I can but hey nice support.

A bowden tube printer which I could print PLA, PETG, TPU like a joke, slice and print.

This Prusa I need to keep an eye on the idler screw pressure:

- Too much and I have under extrusion like the pics on this post (????????????????????????????)

- Too little and no extrusion at all. Happened tonight and I was like "wtf now?"

- TPU you are supposed to release the screw all the way or the whole thing will jam. I haven't tried yet on this printer.

There you have it.

At least PLA is printing okay somewhat so I am fooling myself to believe that things will get better.

I still help the users having problems, especially newbies as I have been there before and very few were willing to help, but my passion for 3D went to shit because of this printer.

Dude from my city bought this printer for 1.5k, bad luck with fees, he is throwing the printer away coz the problems to buy a Voron. Contacted the support for help and info regarding warranty within Australia and the support basically said to him "we don't give a fc" in another word.

I've vented a lot already about this printer. Hoping for the best lol

Anger management

Yeah, venting is part of anger management 😆

On serious side... I'm considering to get some printer with more decent bed size than my Mini has -somewhere about 250x250mm. And honestly, I just can't decide. Each printer model/brand involves too many compromises needed to be made. And no matter what we decide for, it usually turns out, that particular printer can actually do a better job with "right upgrade" -to do the job we expected in first place.

Back to MK3S. It fits my expectations well enough... except price. Price/performance ratio just isn't there anymore (since MK3 launched). Support... well, if product is good, it doesn't need much of it. On the other hand, thermistor for Prusa Mini is out of stock for over a month (just an example). If at all, then I will probably decide for MK3S clone. Because, even after upgrading vital parts, I will end up cheaper than with original -at least so my thoughts right now. But if I would need printer today, I would probably decide between Biqu BX or Anycubic Vyper.

Just sharing my thoughts...

[Mini+] [MK3S+BEAR]

Right upgrade

Yeah, venting is part of anger management 😆

Anger Management lol

"Right upgrade", personally I wished I had just upgraded my Ender3 V2.

- bed size 22x22x25cm

- you can find high-end hotend, high-end parts anywhere

- easy to manage

- costing around AUD400

The "right upgrade" involved in an AUD1.2K printer isn't right.

I was gonna get Mini+ but 18x18cm was scaring me a bit. It cannot print TPU, well, not as expected or not without some cautions.

Hotend issues, extruder with flaw design, unable to print high temp materials. Again, you kinda can but you shouldn't.

For someone asking for advice, I would suggest buying a printer that works without costing a kidney, an Ender or something else, and spend some cash with upgrades. It will be cheaper and you will be a lot happier.

Support??? Hey Google, Reddit, Discord said hi. As bad as their QAC is, even Creality will send you parts if you contact them reporting problems.

That is how that dude is accepting the fact that he lost AUD1.5K buying this MK3S+ and he is buying an AUD900 Voron.

RE: It is unfortunate

It is unfortunate. You are apart of the 1% who can’t get the printer to work. If you are unhappy, post it for sale on eBay and someone will buy it and get it working. You can use the money to buy the parts for your ender. I have 5 Minis and they all print TPU without an issue. I have no idea why you are having difficulties. I have not had them with any of my Mini’s and Mk3s. My Ender is pure trash. I guess we each have different experiences.

On the upside, you are passing joy to someone else and relieving your anger. Someone like me will probably get the printer working in about 24-48 hours. I have done it with 3 Mk3S printers that folks could not get to work.

Good luck.

Yeah, venting is part of anger management 😆

Anger Management lol

"Right upgrade", personally I wished I had just upgraded my Ender3 V2.

- bed size 22x22x25cm

- you can find high-end hotend, high-end parts anywhere

- easy to manage

- costing around AUD400

The "right upgrade" involved in an AUD1.2K printer isn't right.

I was gonna get Mini+ but 18x18cm was scaring me a bit. It cannot print TPU, well, not as expected or not without some cautions.

Hotend issues, extruder with flaw design, unable to print high temp materials. Again, you kinda can but you shouldn't.For someone asking for advice, I would suggest buying a printer that works without costing a kidney, an Ender or something else, and spend some cash with upgrades. It will be cheaper and you will be a lot happier.

Support??? Hey Google, Reddit, Discord said hi. As bad as their QAC is, even Creality will send you parts if you contact them reporting problems.That is how that dude is accepting the fact that he lost AUD1.5K buying this MK3S+ and he is buying an AUD900 Voron.

--------------------

Chuck H

3D Printer Review Blog

In my opinion, I think the OP understood how Ender works and taking on MK3S+ is whole different beast that they struggled to get it work or had high expection and got frustrated with it. I have seen something like that - not only in 3D printer environment, but in PC customize build (Intel vs AMD, NVIDIA vs AMD), Apple vs Android, Xbox vs PS, and going on. I have seen many people taking out their frustration and claimed their brand is better than this, etc...

It is unfortunate. You are apart of the 1% who can’t get the printer to work. If you are unhappy, post it for sale on eBay and someone will buy it and get it working. You can use the money to buy the parts for your ender. I have 5 Minis and they all print TPU without an issue. I have no idea why you are having difficulties. I have not had them with any of my Mini’s and Mk3s. My Ender is pure trash. I guess we each have different experiences.

On the upside, you are passing joy to someone else and relieving your anger. Someone like me will probably get the printer working in about 24-48 hours. I have done it with 3 Mk3S printers that folks could not get to work.

Good luck.

Yeah, venting is part of anger management 😆

Anger Management lol

"Right upgrade", personally I wished I had just upgraded my Ender3 V2.

- bed size 22x22x25cm

- you can find high-end hotend, high-end parts anywhere

- easy to manage

- costing around AUD400

The "right upgrade" involved in an AUD1.2K printer isn't right.

I was gonna get Mini+ but 18x18cm was scaring me a bit. It cannot print TPU, well, not as expected or not without some cautions.

Hotend issues, extruder with flaw design, unable to print high temp materials. Again, you kinda can but you shouldn't.For someone asking for advice, I would suggest buying a printer that works without costing a kidney, an Ender or something else, and spend some cash with upgrades. It will be cheaper and you will be a lot happier.

Support??? Hey Google, Reddit, Discord said hi. As bad as their QAC is, even Creality will send you parts if you contact them reporting problems.That is how that dude is accepting the fact that he lost AUD1.5K buying this MK3S+ and he is buying an AUD900 Voron.

Fresh start I guess

In my opinion, I think the OP understood how Ender works and taking on MK3S+ is whole different beast that they struggled to get it work or had high expection and got frustrated with it

After all the ups and downs, I was somewhat being able to print PLA but then, disaster strikes again.

I started having weird under extrusion lines here and there. A legend on Discord managed to identify the issue with my terrible explanation.

It turns out, the e-stepper gear has a little screw to hold the gear in place against the flat part. Somehow, it got loose so the motor was spinning but not the gear.

How that happened?? I have no idea since I am more likely to oversight screw than to not tight at all.

My guess, assembling without proper lubing the bearings following the book was generating a lot of friction/vibration. I could feel and see the printer shaking.

A week later and after reading a post I did notice that some screws were loose.

That is when I upgraded my X-axis and add lube to the bearing. Day and night.

I believe I am part of that "1% IN THEORY", with bad luck as @cwbullet mentioned.

And no, I cannot just sell it, I sold my Ender. Yes, I know, stupid me swapping right way what works with a doubtful one.

On the same note, I guess I was part of the lucky ones with Ender, I spent like 8h assembling it, I had read about almost all the common issues and it was a great newbie experience while many other were having all sorts of problems.

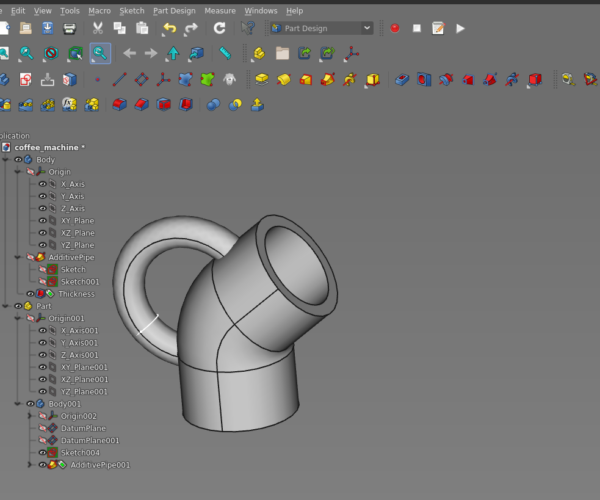

The picture attached is how I managed to get the smooth sheet set.

The new textured sheet should arrive next month so I can try PETG again and TPU.

I am still pissed with everything but it is what it is.

I am back with my 3D designs on FreeCAD and I am trying to forget everything and start again.

End for real

Well, after a rough start we got there.

Part of my problems was a mix of myself, the printer which some things I just refuse to accept, and too high expectations.

I have had the worst and yet the first layer shift ever since I started into 3D printing on a 30h printing, that was fucked.

A lot of "no idea why the printer did A when everything was set to B" and so on.

I spent last night going over the printer again for the last time, I believe I found what caused the layer shift and I just could not believe it.

My ghosting is basically gone, the print quality is as expected.

That is it, time to move one.

Well, glad you found it, whatever it was.

Mystery man.

Troll

He might now be, but we do get a few trolls out looking for a response.

Mystery man.

--------------------

Chuck H

3D Printer Review Blog

Bed thermostat cable

My partner mentioned that in the middle of the night she heard a loud bang.

It turns out that thin and fragile cable from the bed thermostat got stuck in the bearing.

- How it got there? Good question.

- How it didn't break? If that happens I hope this printer can identify that and stops

- How the whole thing didn't go bad or fire? Luck

There is no natural explanation for what happened, the cable was tight along the bed power cable within that thermal runner.

It is a very long cable so it managed to run when the bed pushed it without breaking anything.

I gave special attention to that connector when assembling the printer.

I saw a Prusa post with that part melted asf so why. For whatever reason behind that, I just didn't wanna have the same experience.

My textured sheet should arrive soon so I can print PETG again. For now, I just added a zip tie to prevent the cable from moving more than the bed movements requires.

I am slowly printing parts that should come by default like better support for that same cable I mentioned, it bends down and does not stand straight.

LCD clips instead of pushing the whole thing within the t-slot, better cable management cable, you name it. But I need PETG.

But that is a discussion that many will disagree coz "Prusa works out of the box" and I really don't care.

Toll

It should read that he might not be.

He might now be, but we do get a few trolls out looking for a response.

Mystery man.

--------------------

Chuck H

3D Printer Review Blog

Well, after a rough start we got there.

Part of my problems was a mix of myself, the printer which some things I just refuse to accept, and too high expectations.

I have had the worst and yet the first layer shift ever since I started into 3D printing on a 30h printing, that was fucked.A lot of "no idea why the printer did A when everything was set to B" and so on.

I spent last night going over the printer again for the last time, I believe I found what caused the layer shift and I just could not believe it.

My ghosting is basically gone, the print quality is as expected.

That is it, time to move one.

Hear, hear.. 😍

First, I'm glad you made it. I see you're ready to admit, that some troubles were caused by your mistakes -which is a good attitude, because it makes easier to learn and improve.

Wish you happy printing for many years to come.

[Mini+] [MK3S+BEAR]

Pretty nice prints, specially the hex thing.

I see that you use FreeCAD and I'd like to warn you that it appears to have a nasty habit of producing illegal .STL's. NetFabb is a good repair tool and is included in Prusaslicer. I believe there is a fork of FreeCAD that resolves some issues.

Pretty nice prints, specially the hex thing.

I see that you use FreeCAD and I'd like to warn you that it appears to have a nasty habit of producing illegal .STL's. NetFabb is a good repair tool and is included in Prusaslicer. I believe there is a fork of FreeCAD that resolves some issues.

There's one fairly well known bug in FreeCAD where stray sketches can produce some very bizarre objects, but those who are aware of it know how to work around it.

If you use the Part and/or Part Design workbenches and use good design practice and common sense, it will produce flawless .stl files.

However, if the design is wonky and has such things as cumulative questionable constructs, it can produce some very unclean meshes. GIGO.

RE: FreeCAD RealThunder

I believe there is a fork of FreeCAD that resolves some issues.

I have been using "FreeCAD RealThunder" which covers some issues the official FreeCAD have.

I am a newbie to FreeCAD but it works well. I use Linux so I don't have many options anyway.

I didn't design anything you saw here tho 🙂

A coffee machine steam handle printed in TPU. My cat destroyd the stock one.

Simple but I learned a lot lol

I use Linux so I don't have many options anyway.

Actually, I an a number of other 3d fans use Linux (I use Ubuntu and Suse) for most 3d work. I'm only aware of a few meaningful 3d applications that do not have a stable Linux build.

I'm also a fan of open-source software, so most of what I use for about anything is of that type.

Linux hell yeah

I use Ubuntu and Suse

Noice. I've used Ubuntu for maybe 8y if not more. Recent changes and culture were not so cool regarding the open-source world.

Have been using Linux Mint Cinnamon and I am not looking back. You literally forget that you are using Linux.

Solid 10/10 in any aspect you can think of.

Companies servers run CentOS but my personal "servers" run the old and gold Debian <3

That is as far as my Linux experience goes lol

I like FreeCAD coz it was the easiest to learn from scratch and easier to transfer the knowledge for being close to AutoCAD.

I try to do like a CAD expert would, parts, bodies, constraints, etc.

I avoid it at all costs "shortcuts". I do use TinkerCad from time to time when I need something quick like creating a hole, make a part bigger without upscalling the rest, etc.

I like FreeCAD coz it was the easiest to learn from scratch and easier to transfer the knowledge for being close to AutoCAD.

FreeCad was what was used in one of the very first 3d print classes I took, now several years ago.

Our local 'makerspace' is on a main street right on the border between what you would call inner city and suburbia, near a large college campus. Membership is extremely diverse, all socioeconomic backgrounds and all ages from pre-teens to those who make me look like the youngster, and all backgrounds from technophobe to hardcore robot-maker and code cranker.

They used FreeCad because, yes, it is free to obtain, runs on all three of the most common machines that members would have in homes and schools, and was available on some of the lab machines. It was relatively easy to teach and learn in a few hours from the 'now place another cylinder and do a cut' first baby steps to actually drafting a small part that could be exported, sliced and printed in 1/2 hour of lab time or so. It loaded onto the laptop I used for the class without issues and I made my first from-scratch draft on it (a model railroad tunnel portal, using a real-life photo as a model) which I did not print myself (that learning curve would come later) but just left the .stl at the desk and had the staff run it.

In a previous job (I'm now retired) we had both AutoCad and LibreCad, and I dabbled in both but was never a jock on them.

I do come from a strong Unix background, going back to the legacy SysV-ish and BSD-ish systems (HPUX, Sunos/Solaris, ISC, SCO, Dynix, etc.) so when I became frustrated with Windows I started adopting Linux on my personal machines. My wife (retired teacher) was a Mac fan but now uses Windows for general use, web surfing, gaming, etc. My latest 'desktop installation' is actually a Raspberry Pi 400 in the train room, using their latest Debian-derived system. It's a fair-performing general purpose machine, and will run FreeCAD/PS/Cura but I seldom use that for any significant 3d work.

small world

FreeCad was what was used in one of the very first 3d print classes I took, now several years ago.

Our local all socioeconomic backgrounds and all ages from pre-teens to those who make me look like the youngster, and all backgrounds from technophobe to hardcore robot-maker and code cranker.

That is what I would call "the dream suburb"

(I'm now retired) ...... I do come from a strong Unix background, going back to the legacy SysV-ish and BSD-ish systems (HPUX, Sunos/Solaris, ISC, SCO, Dynix, etc.)

Gonna tell ya, you sound like the best company along with some beer, snacks and forget about the time talking about everything and beyond. Legend! 🙂

I have recently tried some adventures with FreeBSD coz I run a custom OPNSense router along some Pi4 (Pi-Hole + Unbound + WireGuard VPN)

I am far from all of that experience but I am curious and working in IT doesn't help lol

Now on my 30-ish is that I am learning electronics (building an Ikea enclosure to print ASA) coz I need an independent 12v system running from scratch.

And now 3D design lol

Small world 🙂