Mk3 treefrog 50 microns clog

Hello,

I finished assembly of my MK3 yesterday, using the silver (free) Prusa PLA had:

- prusa logo - OK

- Benchy - OK

- gears - OK

(all from SD card)

Today I moved the printer, re-run the wizard, updated to firmware 3.5.0, and again with the silver filament

- tree frog 150 micron (from SD card) - OK

Then I switched the filament to Prusa Lime PLA and had 3 (three) clogs when trying to print the 50 microns tree frog (from SD card).

First clog, I pushed the 1.5 alen key through the PTFE tube and cleared it, while having the nozzle at 280C.

Re-run wizard and first layer cal, printed Prusa logo from the SD - OK-ish (a minor issue with the top layer).

2nd clog I heard the extruder clicking and was able to cancel and moving the extruder while the nozzle was at 280C cleared it.

3rd clog again had to disassembly the idler again and push the filament with the alen key.

All prints failed immediately after the first layer, first layer is fine, after it it clogs.

Now the printer is printing the tree frog with 150 microns with the Lime PLA and seems OK so far.

Re: Mk3 treefrog 50 microns clog

Since you changed filament. Perhaps gunk on the filament, like someone used tape to hold an end.

When you get a clog, best to remove the filament with a cold pull. That way you remove whatever it is that won't fit through the 0.4 nozzle opening. Let the printer cool down to room temp. Important to do this because you want all the filament in the extruder to be cold; if you don't do this, the filament will stretch and not do the job for you. Once cold, open the extruder door so filament is free of the gear. Manually set extruder to 90c. Then start pulling up on the PLA filament. At some point the filament will break free and you'll be able to pull it out of the nozzle.

The end you pull out should look like the nose cone of a rocket. A solid filament that suddenly ends in a nice V shape.

Here's a sample of a good pull from the web:

And one done without letting the printer cool down enough, luckily didn't break off, and got the job done:

Re: Mk3 treefrog 50 microns clog

My problem is the fact the it clogs on 0.05mm.

I tried last evening with some Pink PLA, also from Prusa, same thing, after first layer it clogs.

Re: Mk3 treefrog 50 microns clog

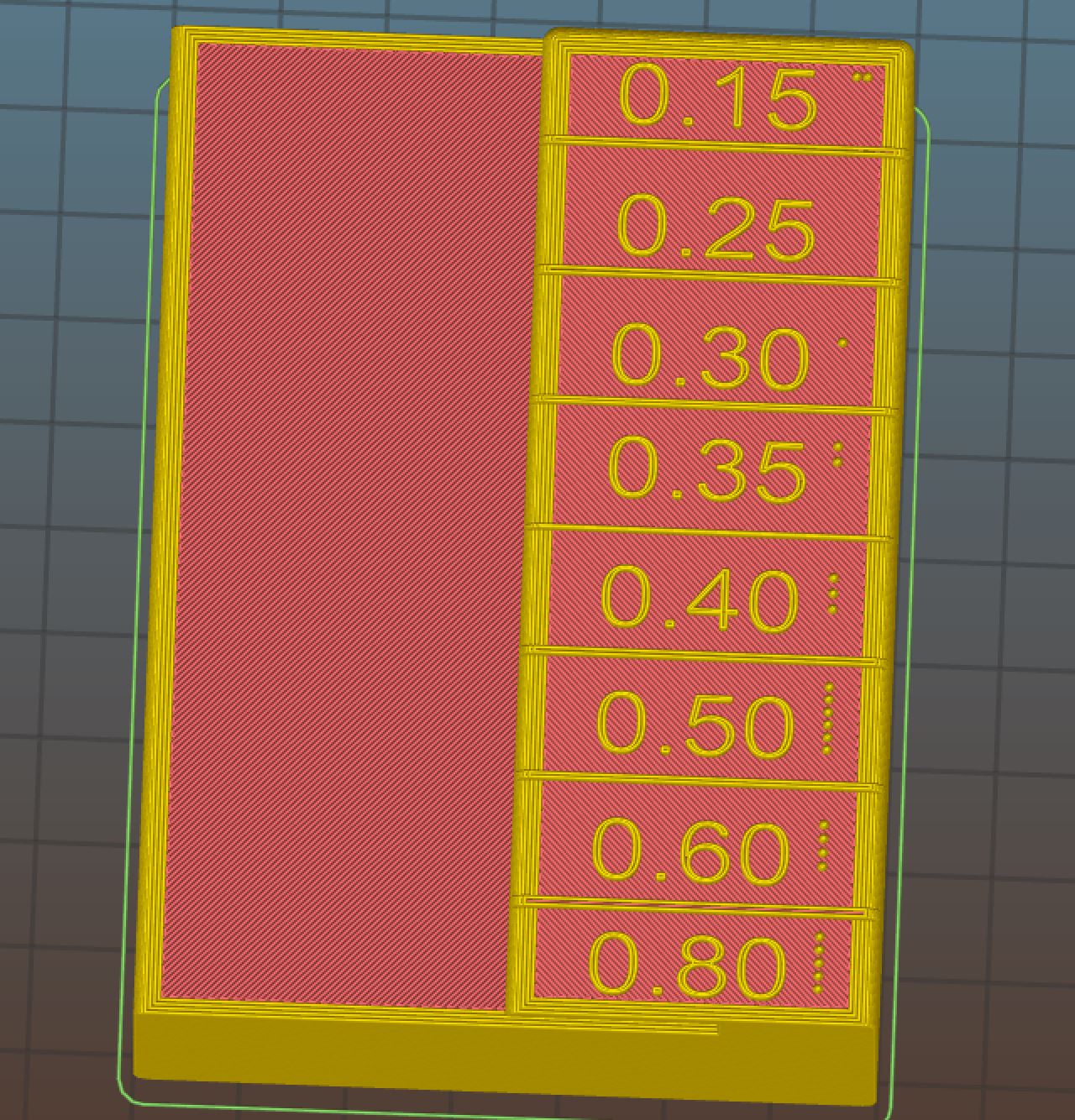

Endless cold pulls later, my extruder still clogs when I try to print anything below 0.15 mm.

Re: Mk3 treefrog 50 microns clog

Just to confirm: you are printing the gcode file from the Prusa SD card, and not trying to print something you've created...

With layer height the extruder squeezes out more or less material as it travels. Smaller height means less material volume is needed - the easiest case for an extruder. So really, the issue you are having makes no sense to me. Maybe it isn't clogging, maybe the gear and idler are skipping at lower feed rates... still doesn't make sense.

Have you double checked the idler tension? The two screws that clamp the idler need to be barely engaged with the springs (you want the springs to do all the tensioning, and they won't work if they are compressed too far). Unload the filament and try setting tension again: loosen the the screws until they are free, then very slowly tighten one until it contacts the spring. Then tighten the second screw until it touches its spring. Then add a full turn to each. The extruder needs very little tension to work properly, and too much tension causes problems. The ends should be about flush with the door surface as shown here.

Also - there's a known issue with the door - the idler axle isn't long enough, so it needs to be pressed beyond flush with one side so it contacts both of the axle supports. Some users have found their axle hasn't connected both sides and have extrusion problems.

Re: Mk3 treefrog 50 microns clog

OK, so 0.05mm countless attempts with the frog from the SD and some "custom" using Slicer PE, all result in clogs.

0.1mm - Marvin from the SD, 2 fails, some custom stuff was successful, meaning the print was completed, but only by me keeping guarding it, at the first extruder "clicks" (10-15-20 minutes into the print) I did a "change filament" and it was again working for 10-15-20 minutes but the results weren't as expected.

What I did:

- checked are re-check idler tension

- checked extruder bolts to be tightened

- checked and readjusted X & Y belts

- checked Z-axis bolts

Now I'm printing an extruder body since my PTFE tubes have arrived and I want to change/inspect mine and since there is the danger to break the extruder body when taking it apart it's better to play it safe :).

Re: Mk3 treefrog 50 microns clog

before you rip the printer apart, try a 0.05mm treefrog, sliced with standard settings apart from 0.4 mm retraction?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Mk3 treefrog 50 microns clog

I don't think it's a nozzle clog. Did you inspect the extruder idler shaft? This is a known issue on Mk3 printers. It must be pressed in so it connects on both sides of the idler gear. Also, good to recheck alignment of the gears - verify the filament teeth are aligned with the filament path.

Watch the video at https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f69/prusa-mk3-working-solution-for-clicking-extruder-u-t25901.html#p116236

Re: Mk3 treefrog 50 microns clog

Ok, I fixed the door and shaft, I replaced the nozzle with a new 0.4 brass nozzle.

This is how the treefrog 0.05 from SD came out (I stopped the print).

Re: Mk3 treefrog 50 microns clog

Leave the filament in, take a photo of the filament path looking thru the door window... also wouldn't hurt to then open the door, flip it up, take another photo to post.

Also - I'd like to know if you are printing the included file MK3_PLA_Treefrog_50um_3H_40M.gcode that is on the SD card you received.

Re: Mk3 treefrog 50 microns clog

Yes, it is the MK3_PLA_Treefrog_50um_3H_40M.gcode file from the SD card that came with the printer, filamnet is Prusa PLA.

I did several photos, it's kind of hard to position the phone for these.

Re: Mk3 treefrog 50 microns clog

I can't say exactly what stage of assembly or disassembly the door was in when you took the photos. But if first image showed the door in the "operational state" the two tension screws were much too loose. It varies, but the two tension screws should thread completely through the nuts and come out the door side where the threads are almost flush with the door surface. Here's another pic - this is my door.

Other than that, nothing obvious other than filament debris that indicates the teeth are slipping and grinding away the filament. You might try a higher tension on the door screws, tighten them up an extra turn or two so the ends extend above the door (so you can feel them with your finger).

If the tension isn't the problem, I'd probably start talking to Prusa about possible issues... Honestly, I'm out of ideas and I can't think of any other mechanism that would cause the symptoms you're having.

Re: Mk3 treefrog 50 microns clog

TL;DR; - fixed the door shaft and re-did idler door tension

@tim.m30 first of all I want to thank you for your help, I have successfully printed my 0.05 treefrog today.

My relationship with the idler door tension screws has been a harsh one so far but we've come to some terms.

The problem was that first I had to add a lot of tension to those screws because the door shaft wasn't inserted properly, this caused for a bit of clicking and squeaking but I found a "sweet spot" and it was printing fine on 0.15 and 0.2 layers.

After I fixed the door shaft I added too little tension to the door and again, extrusion problems.

Now it prints fine, on top of the above I did a top to bottom check and re-tighten all screws, I also found one of the Y-axis bearings being loose.