Making the move from PLA to PETG with a new MK3S+printer build

Hi everyone,

I received a MK3S+ printer kit for Christmas and put it together a week ago.

I've been slowly building my confidence printing with PLA and tried making the switch to PETG with pretty disastrous results (print head dragging in the material, streaking and blobbing, etc).

I engaged Prusa support and after a very painful process went back to testing things out with PLA and have gotten to the point that I'm getting decent results (spoke to a very sharp gentlemen at Prusa this morning who quickly zeroed in on some of the issues).

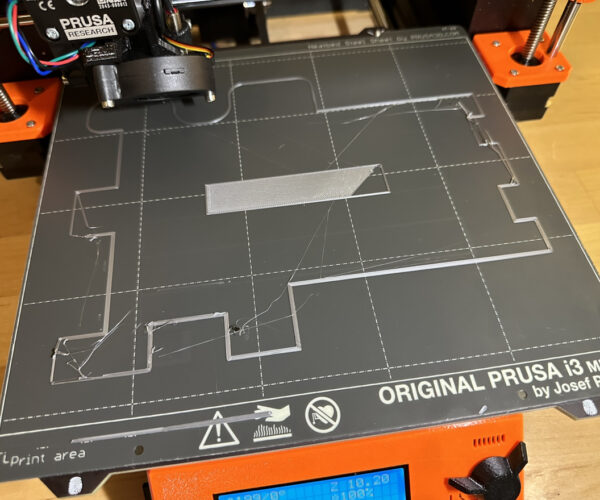

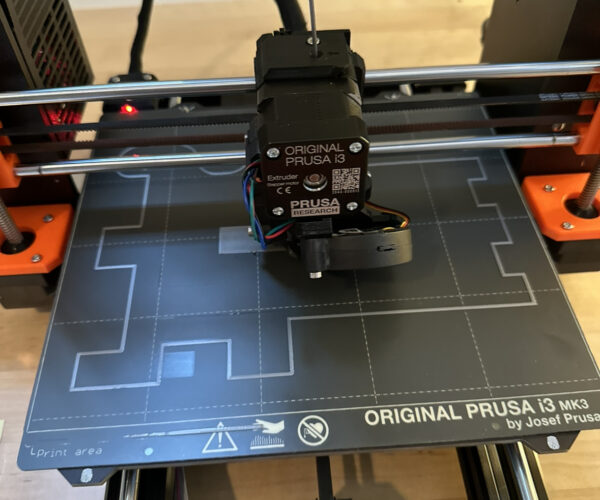

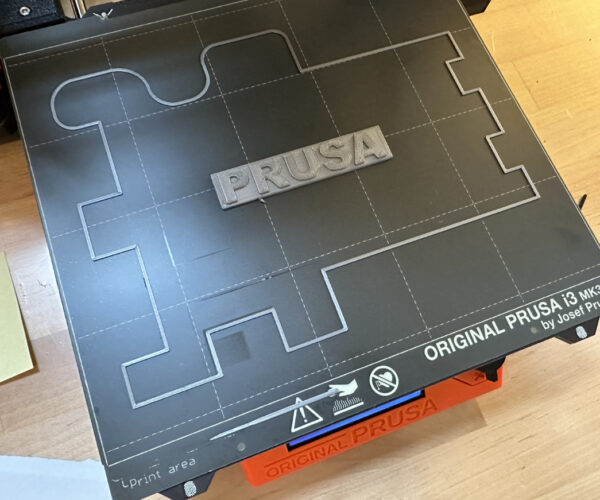

You can see in the two provided photos the difference that just changing a few settings has made in doing Prusa logo test print. All of the previous troubleshooting steps seemed to assume there was an assembly problem with the printer which apparently there wasn't.

So that leads to my question. What specifically do I need to do if I want to try a PETG print again?

A friend has suggested I should get a textured plate, and I can do that.

Do I need to do a different calibration even if I use the same sheet I am using for PLA when I do the PETG print? It seems that the material lays down quite differently and the Z offset (currently at -1.805) for PLA will not work at all for PETG.

The setting changes that the nice guy from Prusa had me made was setting mesh bed to 7x7, and changing the mesh bed Nr from 3 to 5. He also suggested heating the bed to 100C when doing larger area prints as it will help with first layer getting put down correctly when you are outside of the bed center.

RE: Making the move from PLA to PETG with a new MK3S+printer build

I'm not sure what to tell you as far as what to change. I print almost exclusively with PETG and outside of using the right material profiles in my slicer and making sure my z-height is correct I'm not sure there's any other magic. I've even printed in PLA the other day and that went fine.

The one thing I can tell you is that PETG sticks to the satin build plates extremely well. Maybe even too well. So the textured plate is really ideal in my opinion.

Aaron

RE:

I can definitely get a textured plate before going down the PETG road a 2nd time. It does seem to be pretty common advice that's given.

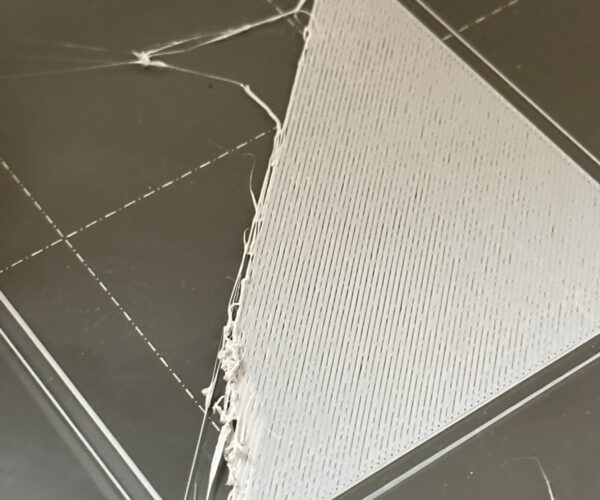

As an example of what was going wrong with printing PETG using the same Z height I was using with PLA see the following reference photo. This was after Prusa recommended raising Z from my at the time -2.1 to a value of -1.8 and the print nozzle would begin to drag into the printed material.

RE: Making the move from PLA to PETG with a new MK3S+printer build

The rough sheet is super for printing PETG. But I can print PETG fine on the smooth sheet. When I didn't have the rough sheet, I used glue stick so it didn't wreck the PEI but I didn't change the Z for a filament.

RE: Making the move from PLA to PETG with a new MK3S+printer build

Okay thanks for replies. I will try a PETG print later today or tomorrow and see if maybe the failures I was having originally were a fluke.

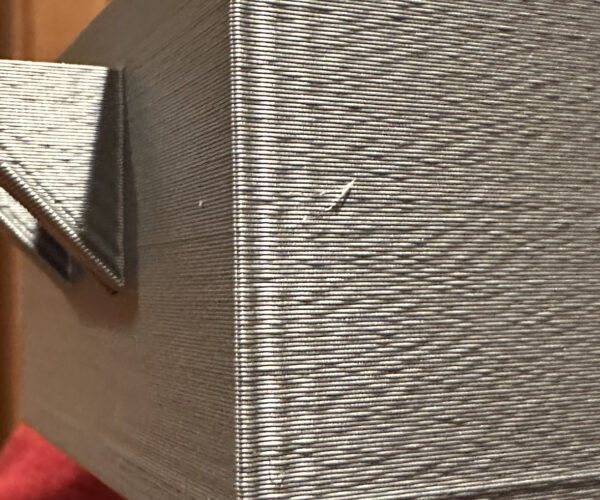

I completed a draft quality print of a storage drawer today with PLA and the print came out pretty well other than what looks like a very slight stacking issue on one corner of the print.

RE:

Okay I got brave enough today to try another PETG print. I printed the PRUSA logo after making sure to choose the right material in slicer. I used the Prusa PETG profile and printed on Overture PETG and it seemed to work well enough. I printed at draft quality with default temps for the material. I watched closely as it was printing and I do notice that since the Z height is different across the plate if your Z is too low it might end up getting into trouble at some point. My old Z was -2.1 but the Z I have now after more PLA practice is -1.8

So I guess whatever was going on before has now been resolved.

RE:

Using this method for adjusting the Z has improved my life dramatically. If you're not using this and a set of calipers it's hard to dial it in. I do think that maybe PETG is a bit more sensitive to that first layer being fairly well setup.

Aaron

RE: Making the move from PLA to PETG with a new MK3S+printer build

This is great! Thanks.

RE: Making the move from PLA to PETG with a new MK3S+printer build

The Jeff Jordan ‘Life Adjust Z - my way’ routine is an excellent tool to help get your Z height properly dialed in. Good call @extra-fox …

In addition, when I’m struggling with a print in PETG, I reduce the nozzle temperature by 10-15* (maybe more, I print a lot of Overture PETG at much lower than suggested temps) from the recommended settings and slow the first layer speed down significantly; maybe as much as 50% on certain prints.

Experimenting with these two settings, plus a proper Z calibration should help improve your results with PETG prints. Try printing a temperature tower model to help you zero in on a good temperature zone for low stringing with good adhesion.

I don’t have the smooth print sheet but follow the advice to use glue stick or another release agent like Layerneer or Magigoo to reduce the chance of damaging the PEI sheet.

Let us know how you make out.

Cheers