loose hotend?

My first layer keeps getting spoiled. I've replaced my PETG filament with a fresh spool, same problem. I noticed while cleaning the tip while hot that it has a little side-to-side movement, about 1mm. Now that it is cool, it barely moves. Is this normal?

RE: loose hotend?

No.

Have you ever swapped nozzles?

RE: loose hotend?

My first layer keeps getting spoiled. I've replaced my PETG filament with a fresh spool, same problem. I noticed while cleaning the tip while hot that it has a little side-to-side movement, about 1mm. Now that it is cool, it barely moves. Is this normal?

Need more info.

--------------------

Chuck H

3D Printer Review Blog

RE: loose hotend?

@cwbullet

I've rebuilt the head before when it filled with melted plastic that got backed up from the extruder tip. I have also changed the extruder tip. (BTW how many kilo of PETG can I expect to run through a tip before I should replace it?)

RE: loose hotend?

@joe-7

I have several that I have been using for 2-3 years with probably 100s kilos through them. I keep printing.

--------------------

Chuck H

3D Printer Review Blog

RE: loose hotend?

@joe-7

There are wild swags for nozzle life, like 6 months of continuous printing. Others say dozens of kG.

My guess is a brass nozzle printing common PLA or PETG a nozzle will last hundreds if not thousands of kilograms. I've been printing using the same nozzle the past year and a half and have not seen any signs of wear. Dozens of kilos of PLA and PETG and some partial spools of PLA and PC mixed with carbon fiber thrown in.

RE: loose hotend?

This is the only nozzle that I can definitively say I've worn out - I use the term loosely - it was still printing quite well when I pulled it from the printer. It is not brass: it is an even softer nickel plated copper nozzle.

It is worn only because the nickel plating and tip has abraded away grinding on parts with grid infill; the wear is not due to filament flowing through it.

RE: loose hotend?

@joe-7

I do not think this is a nozzle issue.

--------------------

Chuck H

3D Printer Review Blog

RE: loose hotend?

@cwbullet

Any suggestions on where to focus my efforts?

RE: loose hotend?

@joe-7

I don't know ho to say this with any more subtlety - people shoot themselves in the foot by not reading instructions so often then come to this forum seeking help than any other cause.

When you changed nozzles, did you folow the E3D-V6 assembly and nozzle change guides? They must be followed to the letter.

Most guys don't bother to read or follow them and end up with serious print issues, not unlike what you are experiencing.

RE: loose hotend?

@joe-7

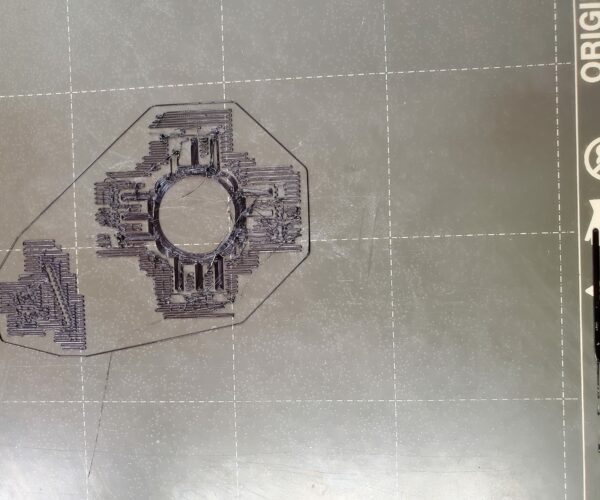

The image above looks like the Z is off of the bed is causing adhesion problems. Did you clean your bed and redo your Z offset with the nozzle change?

--------------------

Chuck H

3D Printer Review Blog

RE: loose hotend?

@joe-7

I don't know ho to say this with any more subtlety - people shoot themselves in the foot by not reading instructions so often then come to this forum seeking help than any other cause.

When you changed nozzles, did you folow the E3D-V6 assembly and nozzle change guides? They must be followed to the letter.

Most guys don't bother to read or follow them and end up with serious print issues, not unlike what you are experiencing.

And this plus what I posted.

--------------------

Chuck H

3D Printer Review Blog

RE: loose hotend?

RE: loose hotend?

@cwbullet

Thanks cwbullet. I didn't re-run Z-calibration at first because it was working fine last week. Nor did I recalibrate when I replaced the same nozzle after cleaning. But, I guess a variation in torque would explain a need to reset Z. I did recalibrate on your suggestion and it is improved but not ideal. It also appears that the extrusion is oozing out during the leveling process before the first layer and the drip is fouling the layer.

RE: loose hotend?

@joe-7

A leaky nozzle is due to improper reassembly. Read those documents I linked above, tear the hot end apart, and put it back together as the instructions say. If you let it go too long you'll end up destroying the hotend.

RE: loose hotend?

@tim-2

That is what he said he was doing.

--------------------

Chuck H

3D Printer Review Blog

RE: loose hotend?

Before I commit to a hot end rebuild, can I get an opinion on this first layer? Looked pretty good to me with the exception of the x-axis movement where the bead lifted a bit. The underside of the solid layer looked good to me. Anything to pay specific attention to why I do my rebuild?

RE: loose hotend?

@joe5939

Those layer ones would not satisfy me for my prints. And your adhesion is suffering for too much 'something else' on the bed.

For what to watch for during rebuild - read the guides I posted above, Follow them to the letter. There are no short cuts here.