Looking for help with calibration and under extrusion

I've been printing a lot of PETG parts on my MK3S mostly with 0.2mm layer height and didn't have problems until about 2 weeks ago. While doing an 8+ hours print I heard strange noises from the printer in the other room and when I went to check what happened I saw that the spool got tangled so that the filament could no longer be transported. The extruder startet clicking because of that and the print was a mess. I didn't think much about it and restarted the print and it finished without any problems.

Later I switched to PLA to print some miniature figures and swapped the nozzle to an 0.25mm one. I could not get a single print to finish without under extrusion (see the picture of the blue minifig attached). I tried out various things to figure out what might cause the problem:

- First I did another z-layer adjustment (already did that after nozzle change and everything was fine)

- Did another cold pull (already did one before nozzle change)

- Wiped down and cleaned all printer parts, lubed the rods, etc. and did a full "welcome wizard" calibration

- Using higher print temperatures (went up to about 235 degrees with prusament PLA)

- Exchanged the Hotend PTFE-Tube with a new one and made sure it doesn't move

- Exchanged the heater block and the nozzle with a new one

- Exchanged the extruder gears with new ones

I can't get a single print to complete without sitting beside the printer and waiting for the extruder click. When I hear the click I can pause the print, unload the filament and then load it again. The print can then continue until it is finished or the extruder clicks again. Higher nozzle temperatures seemed to to improve the situation, but clicks still happened then. Whenever the extruder gears started clicking it would not stop until I unloaded the filament.

Puzzled I switched back to the 0.4mm nozzle to see if I could print at smaller layer heights with that one. To my surprise I could print fine at 0.2mm, 0.15mm, sometimes at 0.1mm and never at 0.7mm or 0.5mm. I remember having printed at those smaller layer heights before, so something must be out of alignment. (The nozzles have been changed at 280 degrees and I use a 2.5Nm preset torque wrench, the nozzle gap looks fine to me.)

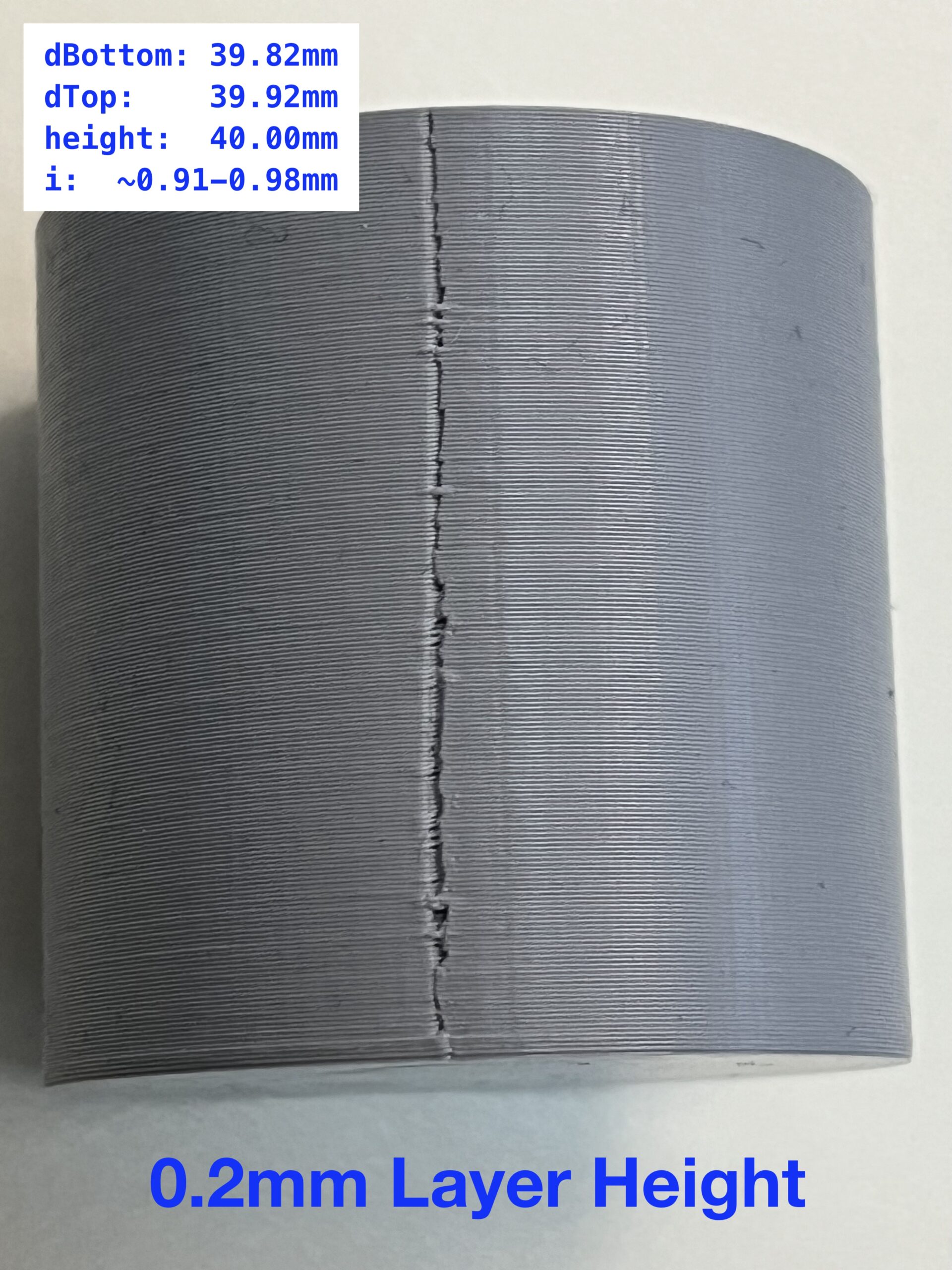

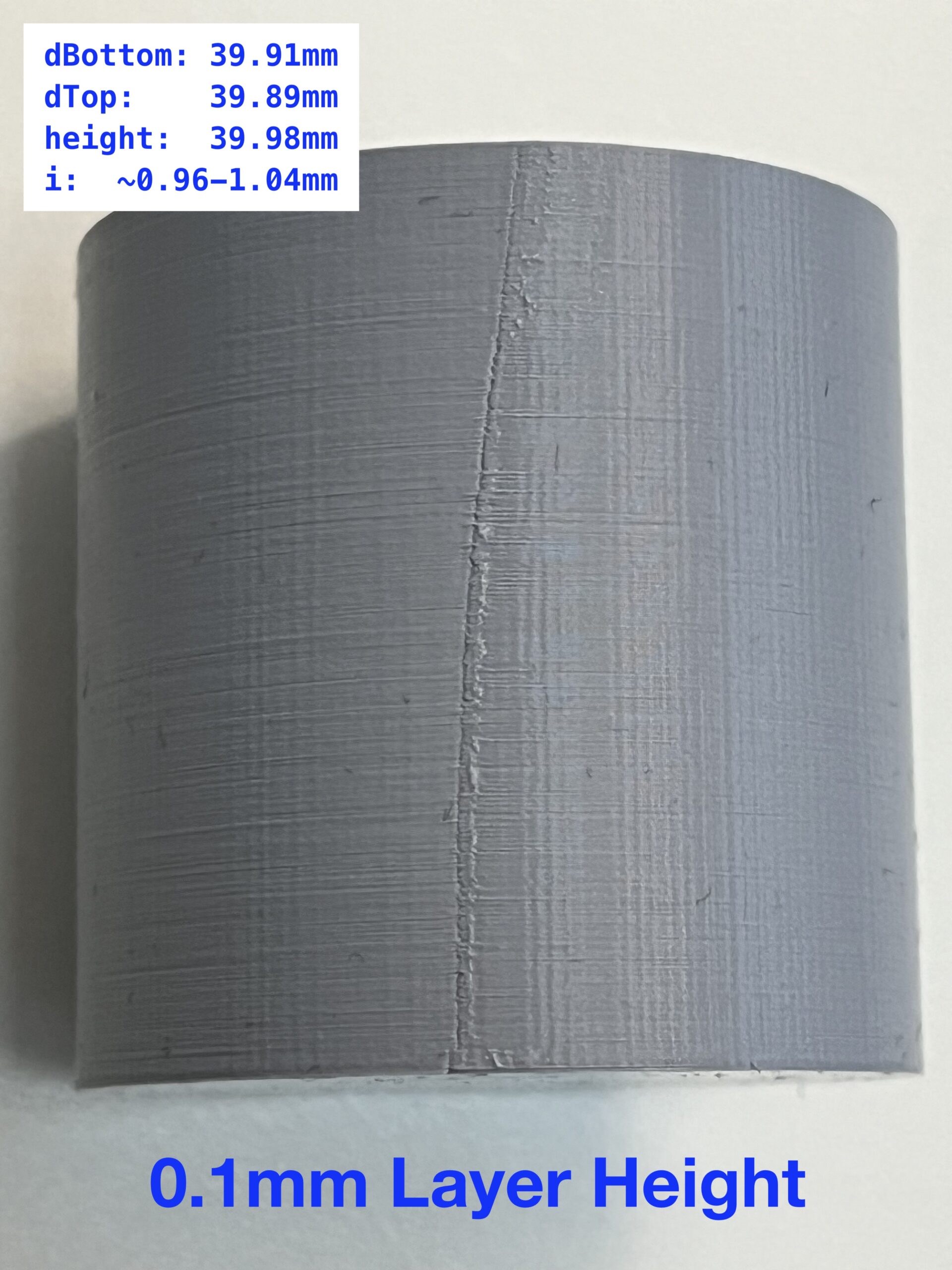

To further investigate what might be wrong I created a hollow cylinder, 4cm height, 4cm width and wall thickness of 1mm. In the pictures attached you can see that there is a strange vertical line that shows up in all of the prints. It's where the printer starts a new layer, something is clearly not aligned there. If this is also causing the under extrusion at smaller layer heights I don't know.

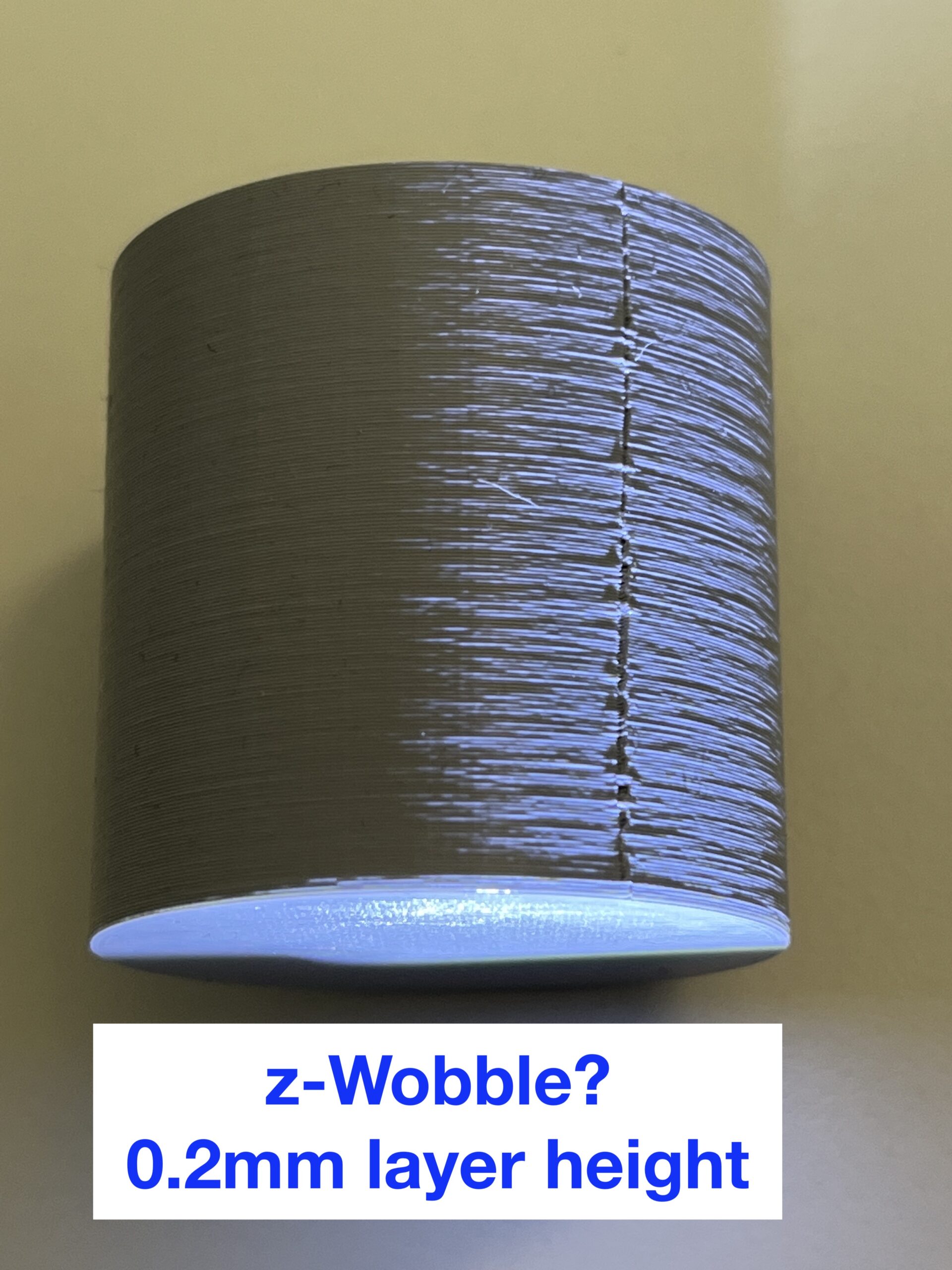

(Also there seems to be a slight z-wobble in the 0.2mm layer height cylinder. I didn't notice much of a z-wobble in the other ones but if it's visible in the 0.2mm one I'm pretty sure it's there. See the last picture, I tried to shine on it from the side with a torch to make the z-wobble visible.)

I'm really puzzled and out of ideas what else I could try out to correct this problem.

I've ordered another set of extruder gears, a new hotend and also the MK3S+ upgrade from Prusa. My next step would be to take the whole printer apart, check all parts and reprint them if necessary (I've got a functioning MK2.5S that still prints fine), but that's sort of a last resort step since it would mean that I'd have to rebuild the whole printer.

I'd be very grateful for any tips and tricks, insights or anything that helps me trying to diagnose what's wrong...

RE: Looking for help with calibration and under extrusion

I forgot to mention that in all tests I used "Prusament PLA" (two different types) and I also ordered a fresh spool just to rule out that it's the filament.

All prints where done in a dry room inside an IKEA lack enclosure that was open during the PLA prints.

RE:

The thinner layers heights are always more demanding on settings. Smaller nozzles likewise - the first setting to try is the extruder idler pressure. Sometimes pale or white fiaments containing lots of pigment need to be printed a few degrees hotter even with standard nozzles, this becomes more likely with smaller ones.

It may pay to fine-tune your belt tensions, make your next print this:

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

It MUST be printed in Prusament PETG or the spring tension will be wrong.

Cheerio,

RE: Looking for help with calibration and under extrusion

Oh, that's very interesting, thanks. I'll try the tension meter. I noticed there are MK2.5s gcodes that I can use because I don't trust my MK3s at the moment.

Do you also think that those strange shifts in the cylinders that I printed are related to belt tension?

Indeed printing thinner layers and with smaller nozzle sizes is more demanding, I remember when I printed some other figurines about a year ago. Last time however I could get stable good prints by adjusting nozzle temperature, extrusion widths, print speeds and max. volumetric speed. However this time around I couldn't stop the extruder from under extruding.