RE: life adjust Z - my way

Got it, thanks for the clarification.

Your Z height still looks too high to me, based on your posted photos. If you are printing with the nozzle too high the results will always be uneven.

Try being more aggressive in dialing your nozzle height down. As an example, if you’re at -1.o58 and you dial down to 1.065, the height change is minimal. Keep dialing down through 1.075, 1.085, 1.095, etc, and watch what’s happening on the print bed.

When I first started out, I had no idea what I was looking at or what result I was trying to achieve, until I got there. I was really surprised at how far I had to spin the dial to get a solid first layer.

Obtw, make sure your print sheet is super clean or you will forever be frustrated with this. There are many posts on sheet cleaning so I won’t go into it here but IPA alone is not enough to clean a dirty sheet. Fingerprints and skin oils are the enemy.

Good luck, you’ll get there!

RE: life adjust Z - my way

This has worked for me as well, Thanks again!!

hi community

just want to share with you my way of finding the right correction value for the life Z adjustment.

just in case that somebody still tries to get it right with the v2 calibration gcode that came with the kit, which i think is only of limited usability.💡

find attached a little gcode that should print a 75x75mm surface with 0.2mm height (PLA settings).

i simply print this file in a bright color (takes about 12 minutes) and change the life Z adjustment level in the middle of the print, when the diagonal of the square is reached.

so a little film is printed. a good idea is to write the settings with an edding at the sheet 😉 .

i repeat the procedure until i get a completely smooth and homogenous surface.

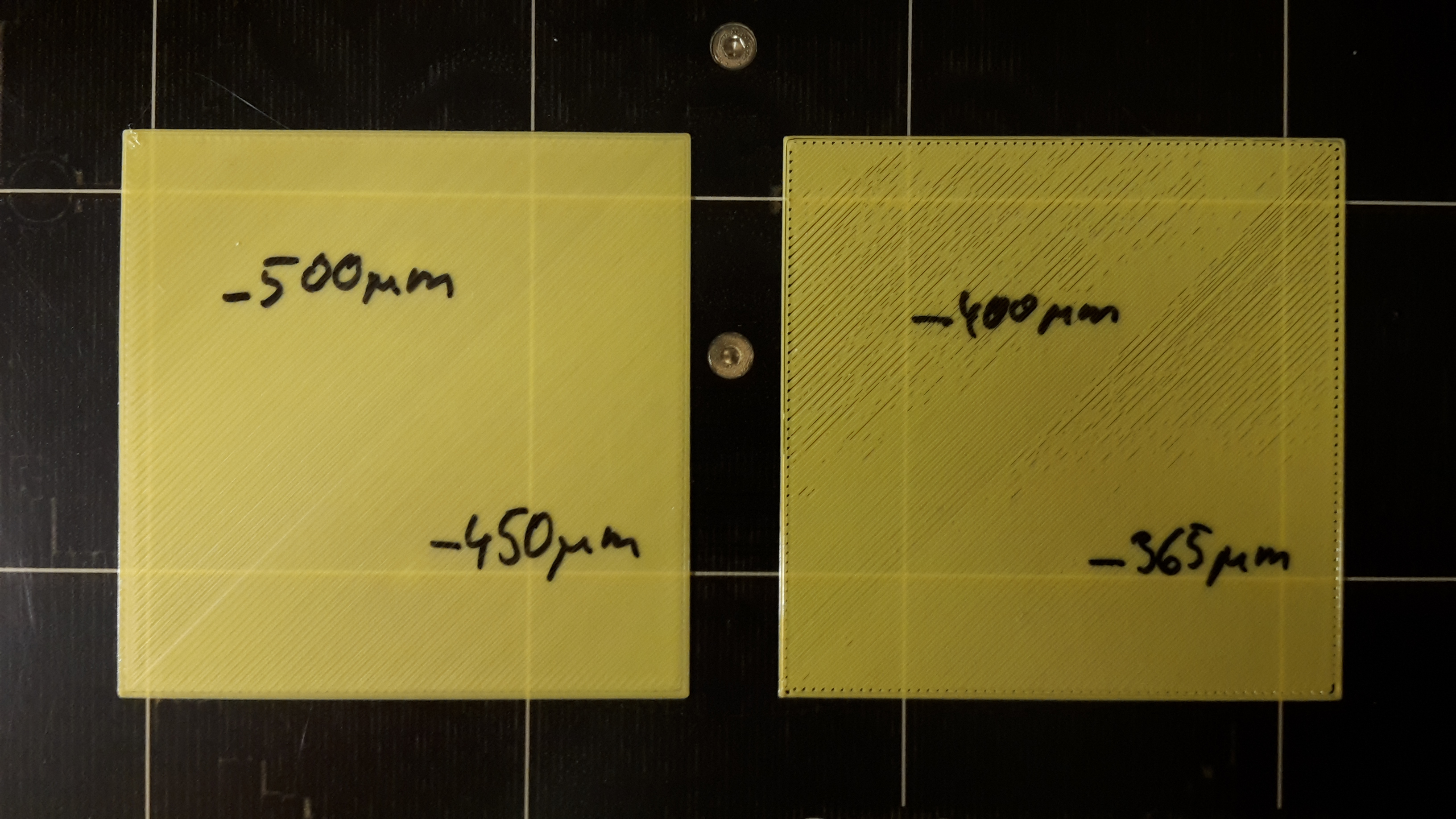

in addition it's a good idea to measure the thickness of the film with a micrometer gauge or a digital vernier calliper ❗➡ when you look at the attached picture, you can see at first sight, that the right foil (with the -365um and -400um) shows some small gaps, which indicates that you need to squish down the nozzle a little bit more.

furthermore you can see that the -500um setting delivered the best result, and as you can guess: it's thickness was exactly 0.20mm.anything more to explain ?

update:

just forget to tell you how you can get the film off from the heatbed without damaging it:

just use coolant spray at one edge. the sheet will immediately curl up and you can get it off easy as pie from the printing surface with your spatula.edit 17th january: just replaced the attached gcode file with one where i added a "G1 Z=10.000 F1800" at the end, just to make sure that the nozzle moves up a little bit more (would remain at 0.2mm after the print).

edit 29th of august: removed the first test sheet (which has been downloaded more than 1000 times) and replaced it by the most recent one (v4).

With the advent of the Prusa Mini the files above, proved unsatisfactory,

I add the file below in the hope that Mini users find it useful, the Contents are a .3mf file with the test patch on the build plate, so that you can edit it for new filaments, plus ready made test patches, for PETG, PLA and ABS.

Please let Joan.t know if there are any problems. 75mm square Mini Life Adjust Z.

➡ update (14.01.2018): calibration surfaces for PLA, ABS & PETG (generated with the latest S3D version, lin-advance, G87 and preheat procedure to avoid nozzle dripping (tnx 2 PJR)):

RE:

I've read through a few pages, definitely not all of them, and I have just one simple question. Why is the original test file so popular? Aside from the manually inserted beeps and boops at the half way point, what benefit does this provide? Is it fundamentally different than just dropping a 25mm x 25mm x 0.2mm square on the print bed and slicing it?

Edit: Ok, so that was technically three questions.

RE:

I've read through a few pages, definitely not all of them, and I have just one simple question. Why is the original test file so popular? Aside from the manually inserted beeps and boops at the half way point, what benefit does this provide? Is it fundamentally different than just dropping a 25mm x 25mm x 0.2mm square on the print bed and slicing it?

It´s popular because it´s gcode and many newbies have no idea how to create a square for individual slicing (just a fact and I was there 3 years ago, too). If you can do it, there´s no additional benefit IMHO from using the gcode provided but rather an additional level of complexity as you may have to re-dial your own temp settings for your own preferred filament once you start the pre-set gcode.

Nevertheless, I believe it´s still very important to maintain the gcode files in the thread and Joan does a great job in keeping them current.

Cheers

Chris

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: life adjust Z - my way

Hi all,

Doesn’t anybody find it strange that if someone has issues with this calibration method it’s ALWAYS in top-left half? Saw multiple pictures here, did this myself dozens of times already and always bottom-right looks better or even perfect, while top-left is always “nozzle too high”.

I even looked into gcode if there’s no change after diagonal but that’s not the case. So then what? All MK3s have bed warped towards top-left maybe? There’s cable in that corner, is it possible it’s weighting bed enough to result in this problem?

Also, after hours of calibration I found my sweet spot and difference to obtain smooth top-left while still avoiding squished bottom-right is about 0.050 or so. Isn’t that something SuperPINDA should just compensate for automatically?

Soon I should get my satin and textured sheets and will need to go through joy of calibrating Z again 🙁

RE:

No, I have not noticed any particular issues with the top left or any other quadrant on my machine, nor any tendency for others' machines to do it.

I've actually noticed more of a need to compensate on certain types of filament, such as ABS/ASA, as on my machine the Pinda has a tendency to 'double tap' toward the rear when the heat bed is at the higher temperature for those filaments, indicating that there may be some slight dimensional changes due to the temperature.

Have you been tweaking the left/right and/or the front/rear fudge factors, or have you just been adjusting the Live Z for similar performance on the top left and bottom right quadrants. If you have any particular issues on any side or in any quadrant, this can help you dial things in closer.

The Pinda will do a good job of compensating for slight variations across the build plate. When it 'double taps', it means that it's getting 'soundings' (for lack of a better term) that are out of the expected range and is taking additional readings to compensate.

Have you changed your mesh settings from the stock 3x3 samples to the more precise 7x7? This can be done via the front panel under settings. I also suggest changing the number of probes to 5.

These tweaks will give you more precision in the bed leveling process, but at the expense of a greater start-up time on each print. However, the start-up is still less than one minute, and the expense of one minute compared to the time of a typical print is minimal and time well spent.

RE: life adjust Z - my way

Yes, I’m using 7x7 with 5 probes - for me indifferent than default 3x3 with 3 probes to be honest. I start to believe this PINDA thing is just a gimmick. Also I slightly added on the right side so the nozzle isn’t so close there (having overall Z adjusted so the top-left is ok, but bottom-right now was too close).

As for tendency - maybe yours is ok so you didn’t notice, but in this very topic I didn’t see anyone with leveling problem, who had issues with bottom-right, always top-left. In fact didn’t yet seen one picture with different pattern anywhere.

RE: life adjust Z - my way

I start to believe this PINDA thing is just a gimmick

The many thousands of users with properly functioning PINDA equipped Prusa printers might take issue with that remark.

Some of us actually get a dead-flat perfectly printed coupon.

If you believe your printer is defective, contact Prusa tech support and have them help you troubleshoot the root cause.

Cheers

RE:

Oh, it's not a gimmick at all.

If you have ever struggled through manual bed leveling with leveling screws and test print after test print after test print, you would appreciate the Pinda, or similar methods.

The Prusa MK3 series is very capable of superb and consistent prints.

If you think that there are some inconsistencies over the build plate, try the Advanced Bed Level Correction and tweak the left/right and/or front/rear values as outlined here, and repeat if needed, iteratively. If your top(rear)-left is off, you should be able to compensate.

https://help.prusa3d.com/article/bed-level-correction_2267

I also agree that if it's not performing for you and you think something is defective, contact support and have them make it right.

RE: life adjust Z - my way

PINDA has given me good results. It is just a sensor that is very repeatable so I have no idea why anyone would think it is a gimmick.

Why we have adjust Z is due to the material we are extruding may have varying effects when contacting the plate. I found different color of Prusament I may have to do minor adjustments.

RE: life adjust Z - my way

Oh, it's not a gimmick at all.

Definitely, not a gimmick, but I have to admit that Creality tried to copy it and failed miserably. I am not sure if they have succeeded since. My CR-10S Pro is finicky.

--------------------

Chuck H

3D Printer Review Blog

RE: life adjust Z - my way

Or, if you really don't like the Pinda, you can try a Rube Goldberg makeshift such as this.

RE: life adjust Z - my way

Or, if you really don't like the Pinda, you can try a Rube Goldberg makeshift such as this.

Neat idea. That might be similar to the new XL but I am sure the XL is more elegant.

--------------------

Chuck H

3D Printer Review Blog

RE: life adjust Z - my way

Well ok, maybe I just don't have comparision with what it's like without this sensor. I'll setup OctoPrint soon to see outputs from sPINDA and see what it calculates there.

Overall prints are doing ok, I'm pleased with overall quality (didn't do any benchmarks tho, just actual prints of things I needed), but that bottom layer isn't uniform, some parts are smooth and then there's a patch of flat but visible groves and then again smooth and so on. Nothing large, no holes in the model and the test square is holding up, no separation.

Maybe I'm expecting too much, but I would love to have ability to overlay own offsets to all 49 probes of sPINDA, that top/bottom/left/right option from the menu is very limited IMHO.

One thing that I found strange is that I had to set Live-Z to well below -1.0 (I think it's around -1.350 for smooth sheet and -1.690 for satin) but if I push PINDA higher it has problem with initial calibration, saying it can't find reference points anymore. IDK, maybe I'll contact support for advice/replacement, waiting for new sheets to arrive still, I will need to do recalibration on them and I'll see how that goes.

RE: life adjust Z - my way

Hey everyone, Very new to 3d printing, trying to absorb as much info as I can

Having issues with my first layer and dialing in the optimal settings. Like others in this thread my bed has a skew towards the top left. Right now a bed level correction value of -30um in the rear and left seem to have things working better. However I have noticed that my first layer height is not 0.2mm, rather its usually always 0.25. Even when the square prints out in what appears to be a perfect print with well mated lines and closed corners the thickness is still 0.25. However when measuring the skirt around the square it is 0.2 (0.19 really but close enough). Despite changing the z height value the thickness of the square never seems to reach 0.2mm

Is there anything else that could affect the height of the first layer outside of the Z value that wouldnt similarly affect the the skirt?

Thanks

RE: life adjust Z - my way

Question on performing this with a 0.6mm nozzle. I've been using a 0.4mm and have used this procedure to get a good 1st level. With a 0.6mm nozzle printing a default layer height of 0.3mm should I be adjusting for that thickness or stick to the 0.2mm as PrusaSlicer has the first layer height at 0.2mm?

MINI+ with FW:4.3.3, Bondtech IFS Extruder, drilled out PC4-M8 couplers, 1 piece Capricorn bowden.

RE: life adjust Z - my way

Does the STL exist for this chance? would like to drop the temp used for the PLA as it's set to 225. When doing this cal at this temp, i see PLA slowly leaking out of the threads. May just be somewhat clogged as well.

RE: life adjust Z - my way

Lynk,

You can quickly create your own test patch in PrusaSlicer by just instantiating a "box" shape. Set the Z dimension to 0.2mm and the x and y dimensions to whatever size you wish (I usually use 75mm). In this way you can set the configuration exactly as you wish.

If you have PLA leaking out of the threads your hotend is not correctly assembled and your nozzle is not properly seated. Refer to the guide at https://help.prusa3d.com/article/changing-or-replacing-the-nozzle_2069 for instructions. Pay close attention to the final inspection figures and be sure that the flange of the nozzle is NOT in contact with the heater block or you will have leaks.

Hope this is of some help to you.

Steve

RE: life adjust Z - my way

Actually, I prefer the 3x3 squares pattern rather than the solid rectangle.

It hits the center, all sides, and all corners and takes less time and filament than a large patch. This will give you a good view of both the top and the bottom and let you dial in the Z calibration.

There are several of these floating around.

RE: life adjust Z - my way

JSW,

True, but even this pattern is relatively simple to create in Slicer yourself (especially if you forgo the interconnecting lines) and then you can still customize the settings to your desire rather than depending upon finding one "close enough" for your purpose.

Regards,

Steve