Leaking hotend/heat break/heat block assembly

I3 MK3S since a couple of weeks. I managed to print multiple pieces both in PLA anr PETG, on smooth and textured surfaces.Going up the newbie learning curve on first layer leveling etc... 🙂

I recently noticed a lot of problems with "blobs" showing up in prints... These lead to prints being interupted by "Crash dectected". When trying to continue, the mostly fail as the nozzle crashes into the blob, eventually moving the entire print.

Up to a point I can't print anything anymore.

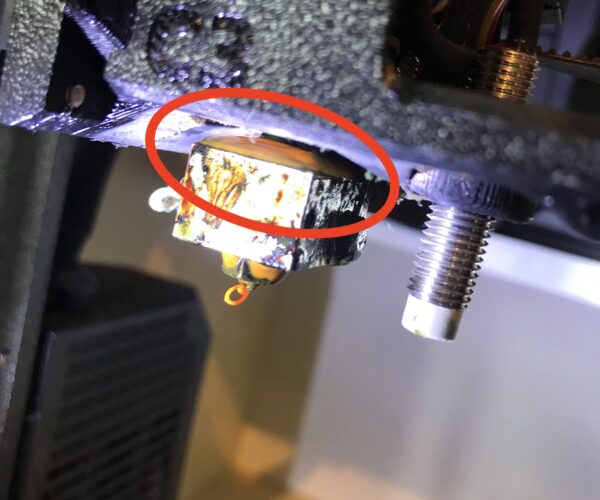

I tracked it back to material "leaking" (?) and accumulating on top of the heat block:

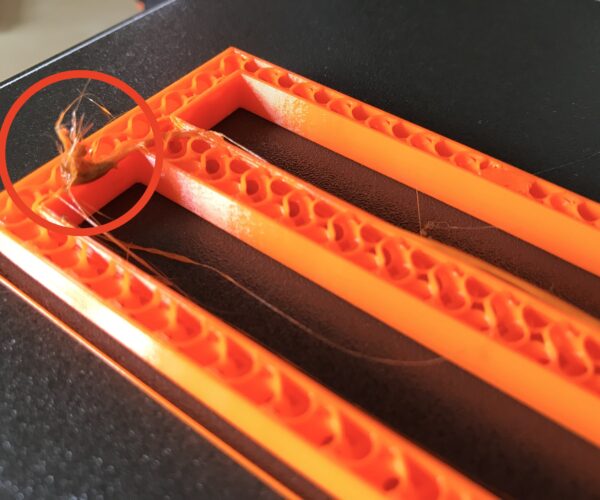

The above picture was taken after I had carefully cleaned everyhing, then started a new print of a piece that would take about 7,5 hours to print. After about 1 hour, a blob had formed that caused the crash detection to activate. As you can see, the entire space above the heat block has filled up again... I imagine it is material dripping from there that forms the blob. Picture of the blob below:

As you can see on this image, this (pretty large) piece started printing verry clean for the first hour. Then suddenly this "blob" appeared that caused the crash detection to kick in...

I've been searching the forum and KB and came across this post: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-general-discussion-announcements-and-releases/leaking-nozzle-heat-block/#post-156622

Looks like this is a similar problem?

I'm still a bit confused about the assembly of the hotend/heatbreak/heatblock/nozzle . I saw somewhere a diagram showing how these fit together but can't find it anymore...

What is your advise to solve this problem?

PS: to remove this mess on top of the heat block, I first do a cold pull to remove any filament inside, then I heat up the nozzle to 285° C and remove all the mess with a small dentist rod.

RE: Leaking hotend/heat break/heat block assembly

Consider the rectangular heat block as a very fancy, long nut into which two pipes screw in. One from the bottom (nozzle) the other from the top (heat break). The ends of the two pipes must ABUTT each other to create a seal. When the two pipe ends fail to come together tightly, you get plastic oozing out of the gap between the two and out the threads. That is what you are suffering.

You will need to disassemble the hot end completely (while it is hot enough to melt the plastic) and clean out all the plastic that has oozed. Follow the E3D assembly directions to install the heat break far enough into the heating block so the nozzle can reach the end of the heat break. Right now your heat break is probably too far up and your nozzle strop screwing in because it hits the heater block instead of meeting the heat break.

RE: Leaking hotend/heat break/heat block assembly

You will need to disassemble the hot end completely (while it is hot enough to melt the plastic) and clean out all the plastic that has oozed.

Hi, thnx for the advise. I guess I need to follow the instructions per https://help.prusa3d.com/en/article/hotend-disassembly-heatbreak-stuck-in-the-heatsink_112677.

Will I have to also remove the heat break from the heatsink? In which case I also will need to have some thermal paste. I probably still have some from when I was replacing CPUs in my PCs. Don't know if that is OK.

The printer is brand new, used about 2-3 weeks and not all the time. The first prints were OK. Does it happen often that the heat break looses contazct with the nozzle?

RE: Leaking hotend/heat break/heat block assembly

I have had the leaking issue many times in recent past [so damn frustrating]. I took the time today to do a tear down and rebuild of the hot end to see what is up. It took quite a bit of time to clean out the threads of both the heat break and heat brick.

After a full cleaning with wire brushes inside and out I discovered much play in the threads. It is my assessment that the threads are allowing leakage. I do not have any thermal paste on hand and did not want to wait. I googled the melting temp of teflon tape. Internet results: @ 260+*C teflon tape starts to change properties, and @ 327*C teflon tape will melt. So I figured I would at least try it.

I had some pink teflon on hand [much thicker than regular thin white stuff] and wrapped the heat break THREE TIMES [always in the direction of threading]. I screwed it in until it resisted, which was about three turns. Then with the heat brick in a vise, I heated the brick little by little with my mini torch until the T-tape got a little more pliable [turning easier with applied heating]. Reheated as necessary until the the heat break threads made contact with the nozzle [backed out a 1/2 turn]. From there, I applied a decent amount of hand-tightness to the nozzle, using a 7mm socket within a screwdriver attachment tool. Then, reassembled the hot end.

Note: don't forget to trim the excess T-tape, I used a razor and tweezers to remove the portions between brick and upper parts. And of course ensure that teflon is completely clear of obstructing the filament pathway.

I only have printed one PETG thing @45 minute exposure. I printed @ 260*C. From inspection everything looks really good. Hoping that this will be a long term fix.

Not sure if I would 100% recommend this fix to everyone with the same issue, but it worked great for me.

Cheers

Jason.

RE: Leaking hotend/heat break/heat block assembly

@j-halter

Its not the threads that are supposed to stop the flow of plastic. They are supposed to be that tolerance due to the different co-expansion of the metals used in the nozzle/block. Its the mating surfaces between the nozzle top and the heatbreak bottom. They are flat and when assembled correctly and at temperature for the final tightening the 2 surfaces press against each other and no plastic leaks.

The heatblock is just a big nut in this instance.

If they have ever not been assembled correctly and you have had a leak then you must ensure that these 2 surfaces are completely clean and smooth again otherwise they will not mate together correctly.