Layers not straight on Z axe

I printed several objects, and I notice that that the layers are not straight on Z axe. Therefore, I printed a high object to test.

Look at the picture (clic to enlarge), on the first layers, there is a shift in the Z axe. Shown with the little yellow line. Then, higher, it is okay.

Do you know where it comes from ? Thank you for your help.

I put the gcode file, if it can help.

Thank you for your help...

RE: Layers not straight on Z axe

Zipped .gcode file

Thank you for your help...

RE: Layers not straight on Z axe

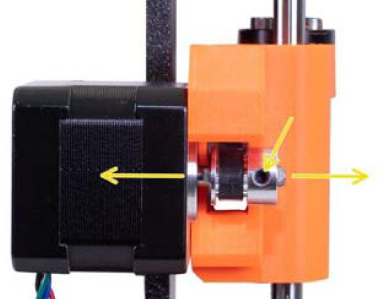

This looks like your X axis is sloppy - are the belts tight? Are the pulleys installed correctly (belt should NOT hit or rub) and the grub screws on the X motor properly tightened (flat first, then round)? If all of that passes, does the X axis move smoothly (bearings not overtightened on the back of the extruder) - those screws should be almost loose.

RE: Layers not straight on Z axe

I can move the X axis by hand. It doesn't go left and right as "freewheel". I can move it smoothly.

The belt is tight, as show here  .

.

When you said "(bearings not overtightened on the back of the extruder), sorry, I don't know which one you are talking about. I checked every picture on the assembly manuel.

Thank you for your help...

RE: Layers not straight on Z axe

Two things - and thanks for checking things. The belt looks loose. I suggest finding the belt tension gauge from PRUSA - must be printed in prusament PETG to get accurate readings (been tested). Get your X belt into the middle of the sweet spot.

For the bearings tightened by screws on the back of the extruder - not referencing instructions. time to move onto conceptual. Think about your extruder body - it rids on the X rails (two parallel rails left to right, one above the other). You tightened a few screws on the back of the extruder body as one of the last X axis assembly steps. If those are too tight - they should be just tight enough to not fall out IMO - the linear bearings on the X axis can be stiffer than they should be - which IMO can cause the slumpy Z you are describing (x axis drift)

RE: Layers not straight on Z axe

Thank you very much for your help. I appreciate you complete answer.

I tied the X belt and I and I untightened the screws on the back of the extruder. I will print again to see if it is better.

Thank you for your help...

RE: Layers not straight on Z axe

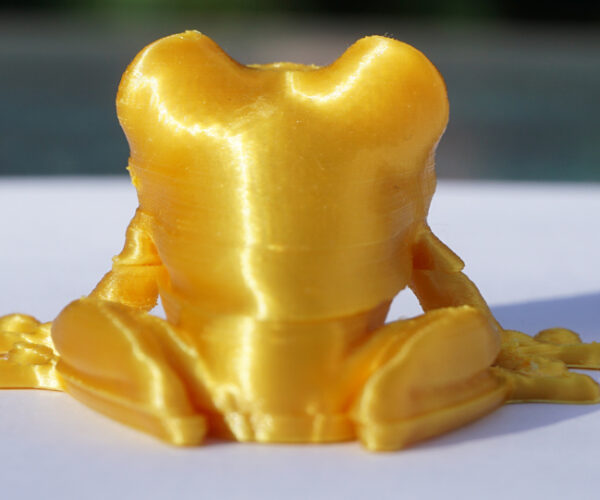

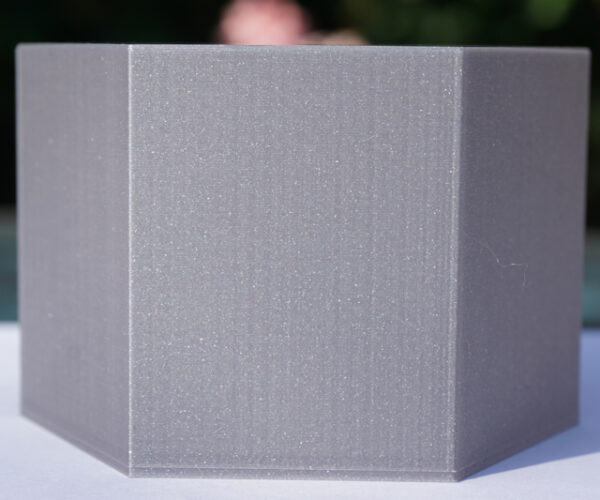

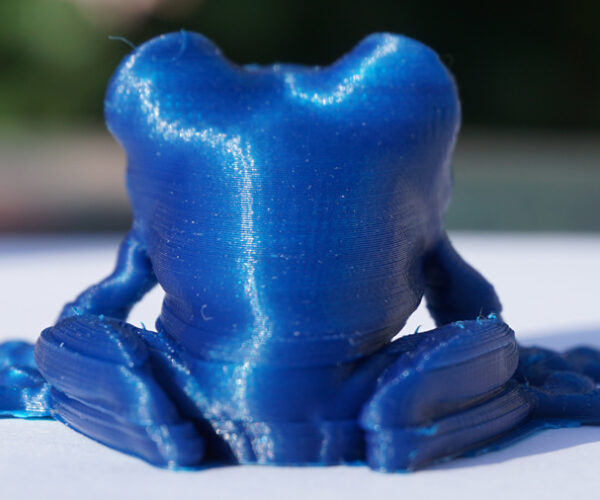

I did more printing. I don't understand, there are problems on X axes, on some objet. See, the pictures. Here is the order in which I printed the object.

- the yellow frog, the first thing I printed when I received the printer. X axe problem.

- the grey octagon. No problem.

I tied the X belt and I and I untightened the screws on the back of the extruder, as you explained here under. - the blue frog. X axe problem.

- The small octagon (2 cm high), no problem with X axes (but still quality problem. I may open a new topic to ask how to improve that.

- I printed again a grey frog (same problem as blue and yellow ones).

Why there are problems with X axes with frog, and the object on my fist post here under. And no problem with X axe with the octagons.

Thank you for your help...

RE: Layers not straight on Z axe

clic on the pictures to enlarge.

Why x axe problems, sometimes only ?

Thank you for your help...

RE: Layers not straight on Z axe

Those are called layer shifts. It's the same as the first problem that you had. If you are sure you tightened the X motor belt properly (using the Prusament PETG belt tension gauge), the next thing to check is whether the little "grub screws" on the X axis pully were tightened properly. There are two grub screws, at offset around the pulley. The first one to tighten is against the flat spot on the motor axel - that one needs to be good and tight (not too tight, you do not want to strip the threads in the hole or break the grub screw). Once the screw on the flat is tightened, then tighten the second one.

If you have not printed the belt tension gauge, I do advise you get some Prusament PETG and print one out to test your belt tension. The numeric indicator in the settings menu is NOT belt tension - it is belt drag resistance.

RE: Layers not straight on Z axe

yes, the ones on the pulley

RE: Layers not straight on Z axe

It's been a long time since you gave me your advice. I tighted the screw, and today to I print again a small thing (8 mm high), it seams much better, the vertical lines are much more straight. Thank you again.

😀 😀 😀

Thank you for your help...