Layer Seperation and splitting

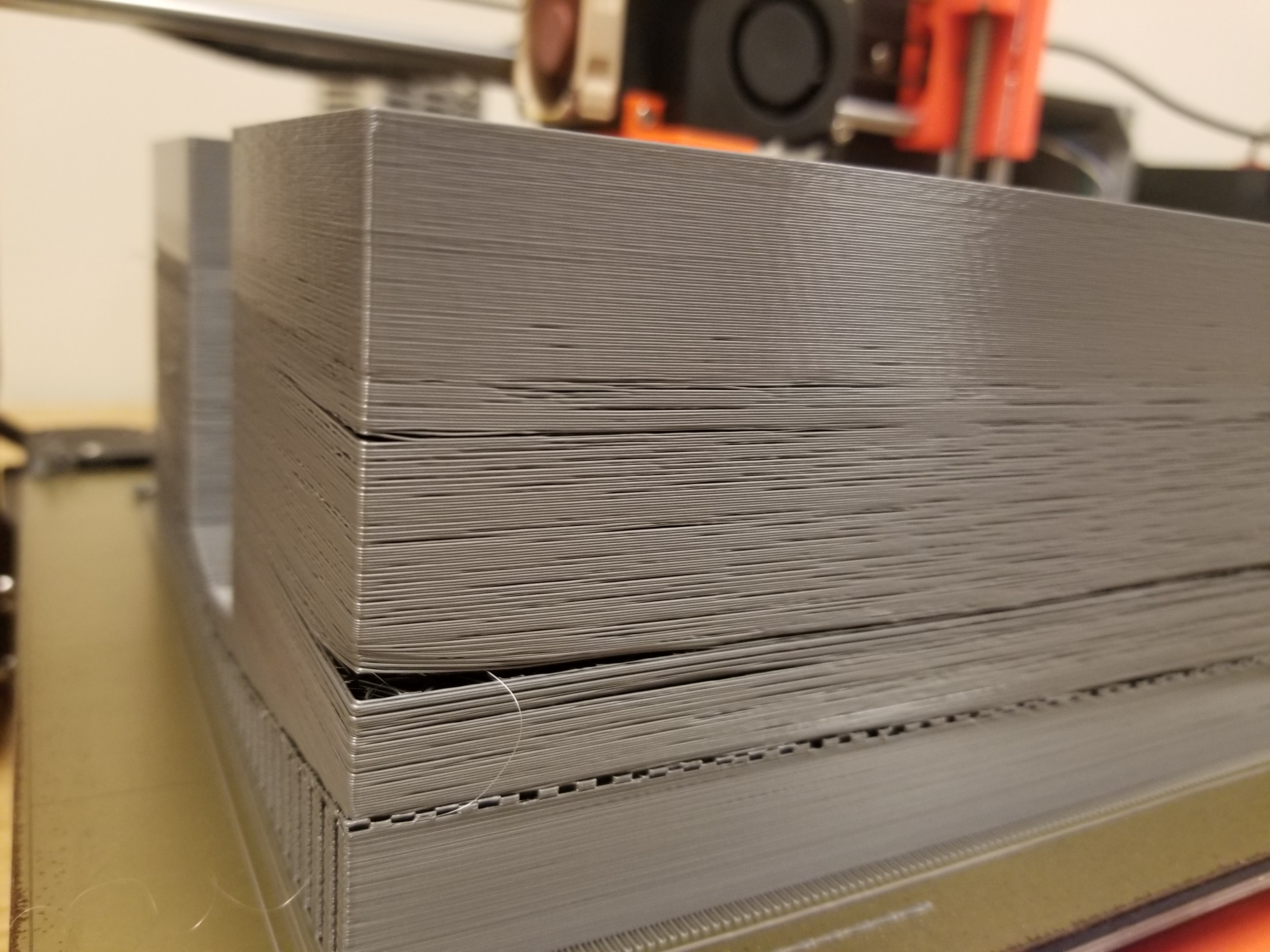

I started a rather large build yesterday after a full XYZ calibration and PEI bed cleaning. The first 4 hours of printing were absolutely stunning. My printer is in a room that doesn't have HVAC so it keeps the ambient temp from the printer. When I came in to check on it after about 12 hours, the print had gone terribly wrong in the middle section, but the last 50 layers or so looked beautiful. All of the print settings are the same for all layers so I am curious why this may be happening.

Prusa PLA Filament

i3 MK3

Recommended .2mm fast settings with Slic3r PE 1.41.0

Fill Density is 5%

Drawn in Fusion 360

Re: Layer Seperation and splitting

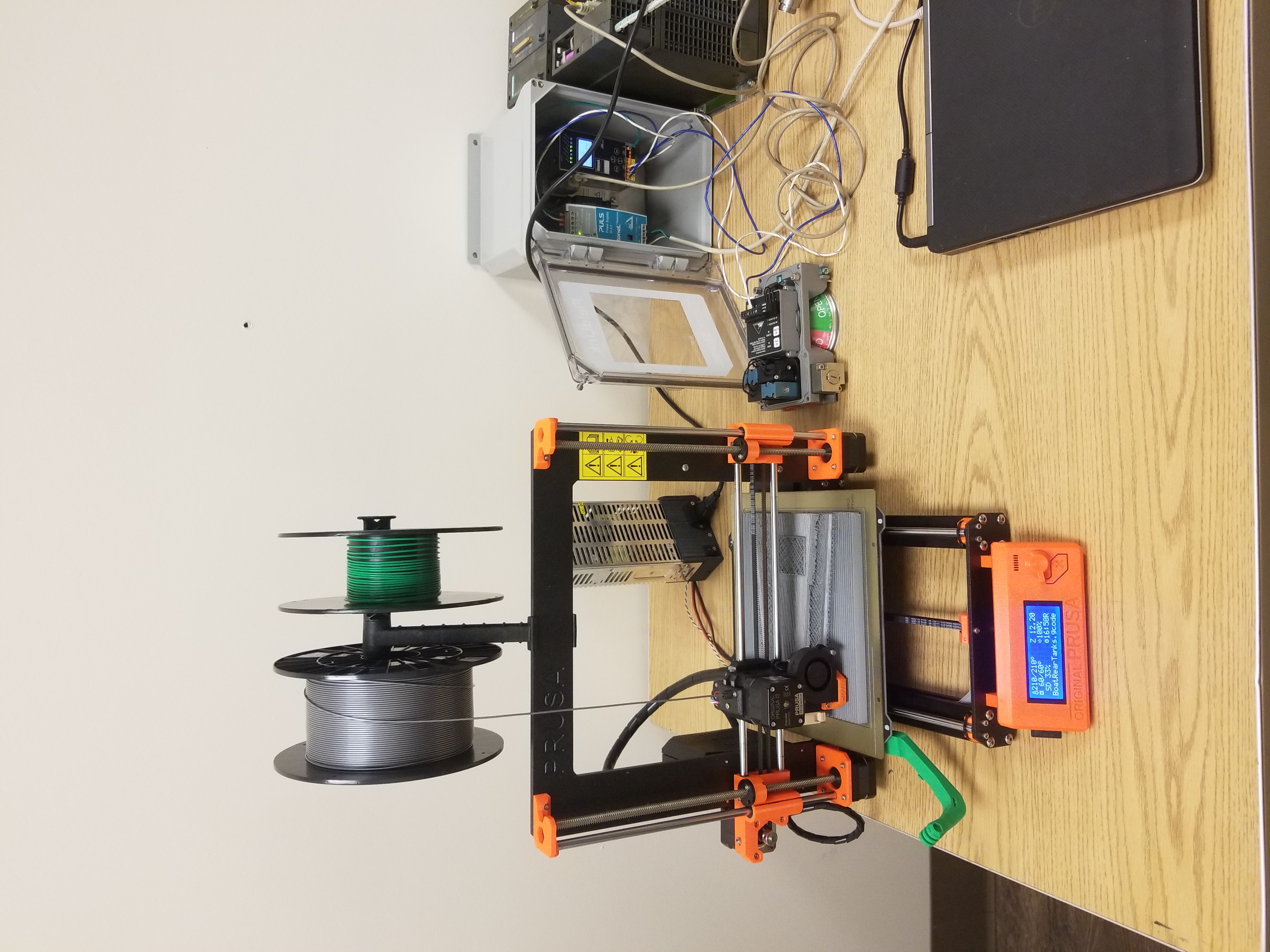

Best excuse for an enclosure I've seen; and I suspect multiple issues are piling up.

At least one of the problems is thermal differential in the layers is causing the part to warp here and there. Could also be some underextrusion; which can make warping and layer separation more likely. A photo looking top-down into the part might help along with the edge view. Also, it "appears" you aren't using "extra-perimeters when needed" option, thus perimeters are being left unsupported; more chance for warpage and separation.

On a side note, from the print, it looks like an upside down Parthenon. Why print it with so much support, what does the final part actually look like??

Re: Layer Seperation and splitting

Thanks for the reply.

I am using an enclosure that you can kind of see in picture 1, but I removed in picture 2.

I am not sure about under extrusion, it is something I may have to explore more. I haven't ever really messed with that setting.

I definitely had the extra perimeters option turned off, but will try adding that in.

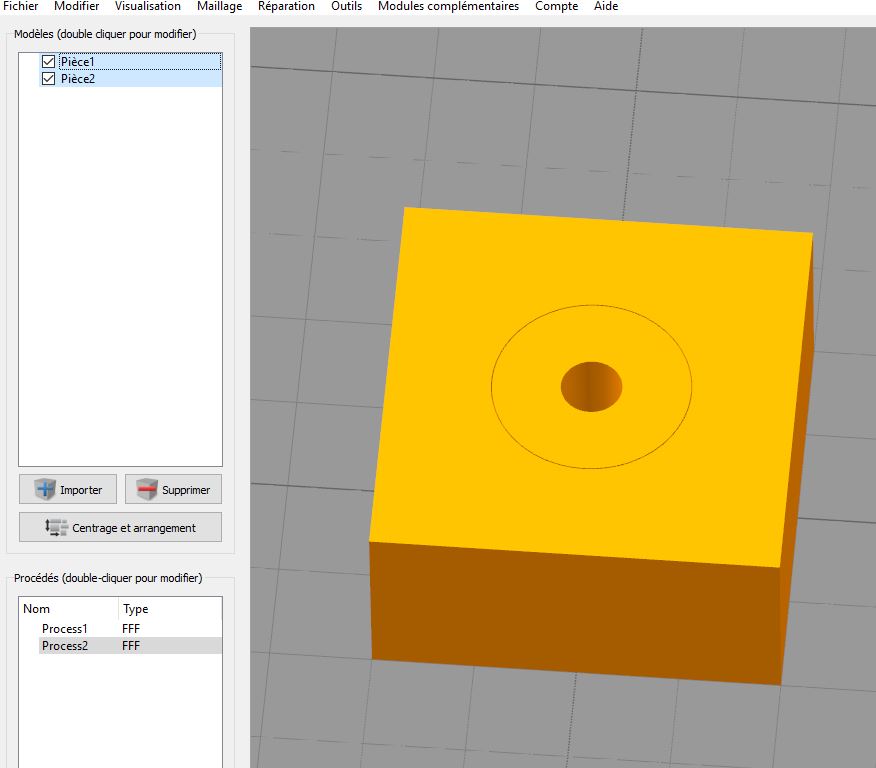

The model is a boat hull and the dead rise is only 15 degrees. The vessel had tanks on the inside so this was the best way to print to minimize supports and bridging. I have since then cut the tanks out of the print and I am printing the tanks and hull seperately which allows me to print without any supports in a vertical position. This went well for 3 prints, then a new issue arose. Not sure if I should continue the saga here or start a new thread, but alas I am here.

The new issue is that the right side of the print area, in all layers has bad layer adhesion. Everything on the left is near flawless. I did yet another full XYZ calibration, but the problem still arises.

Re: Layer Seperation and splitting

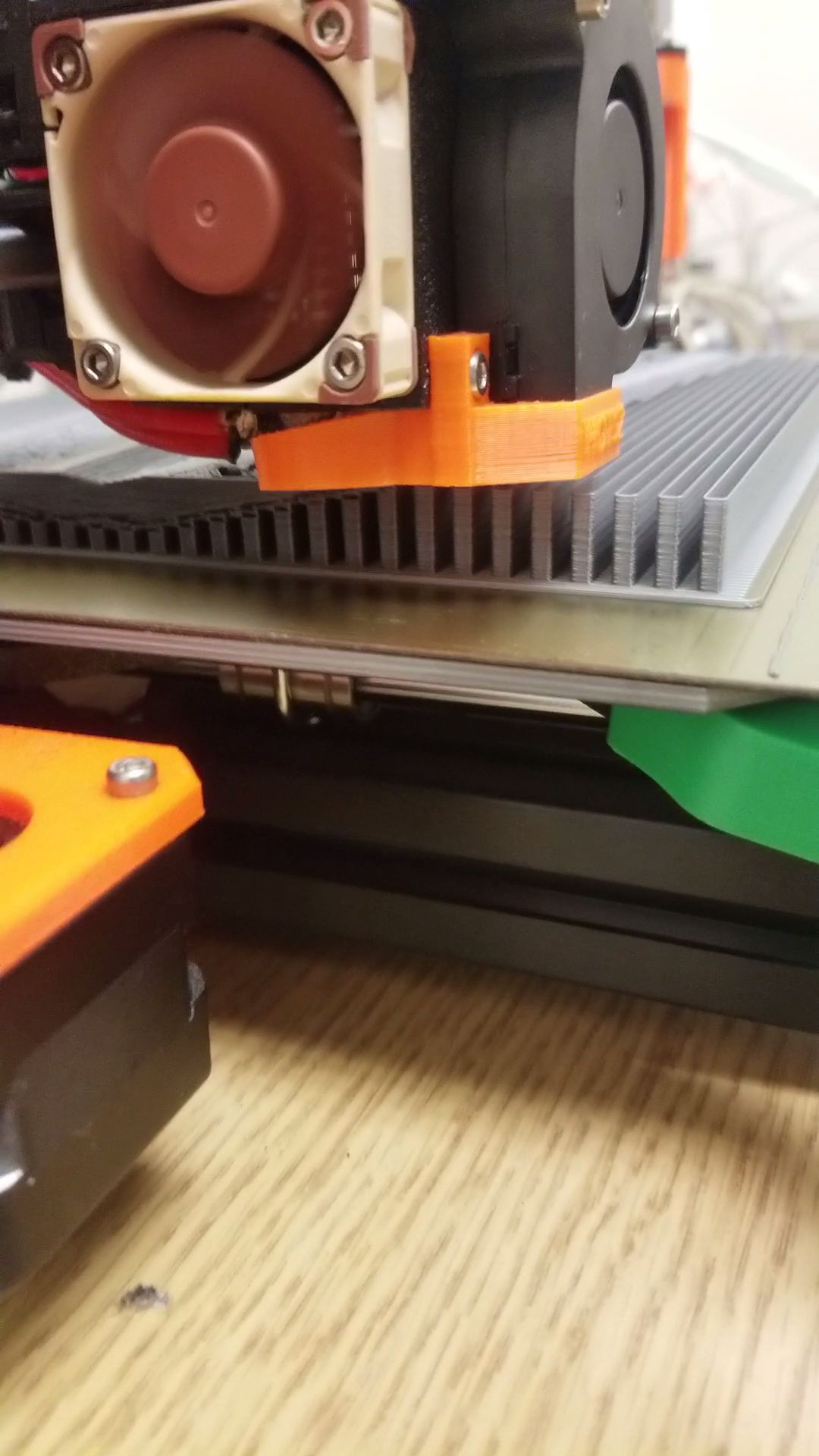

Here are some more pictures

Re: Layer Seperation and splitting

This is one just previous to the current problem.

Re: Layer Seperation and splitting

These two areas are classic under-extrusion typical of a partial nozzle plug. Assuming PLA, try raising nozzzle temp to 250c and manually extrude 100 mm of filament. Look for any popping or sizzling at the nozzle, too. If that doesn't help, a cold pull (or three) will probably clear up the issue.

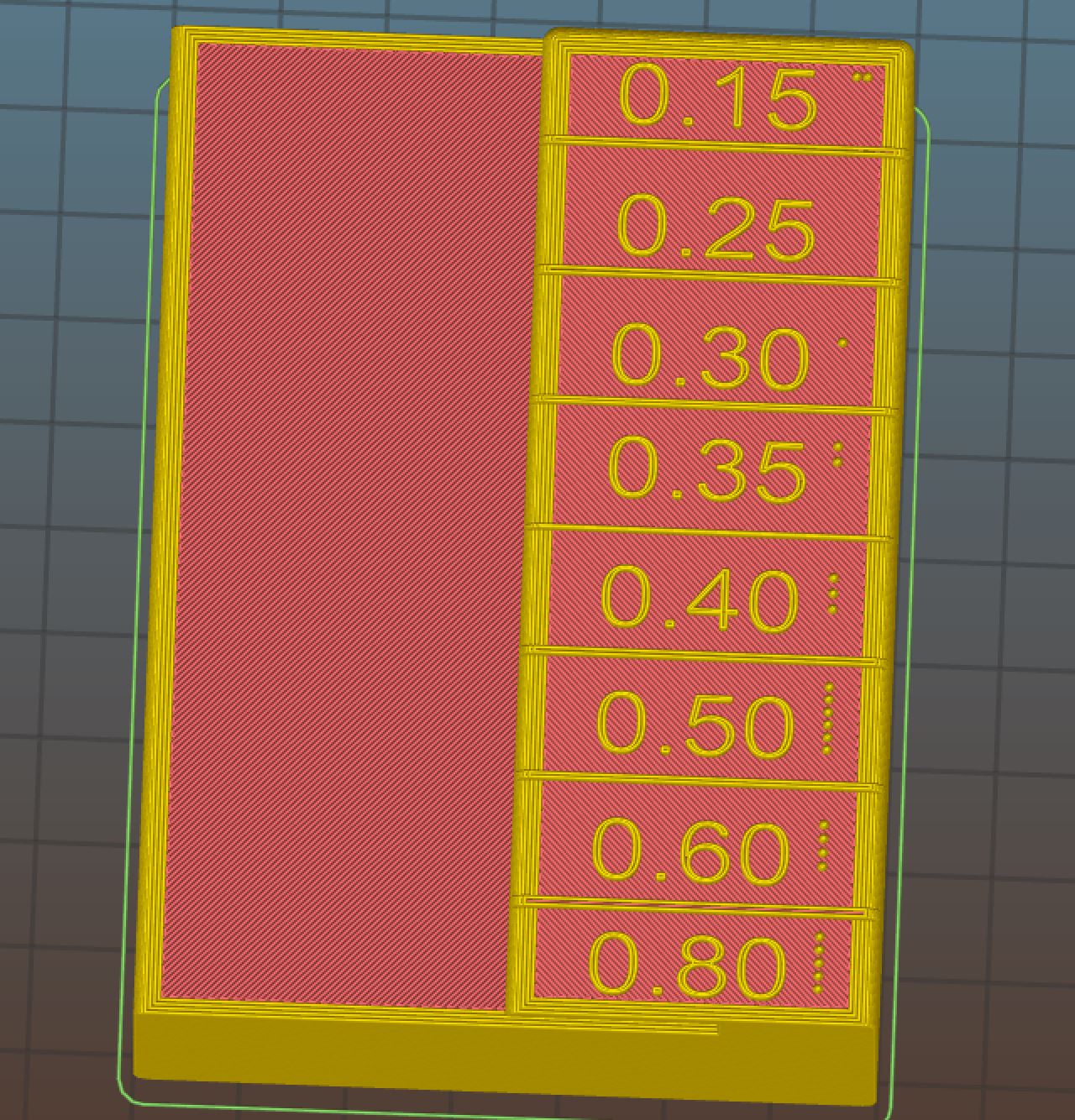

Also - you stated you are extruding 0.2 mm layers. The photo looks like a larger layer. Can you confirm you are slicing 0.2 mm?

And last question: have you modified the print default speeds at all? Printing too fast can also cause this.

Re: Layer Seperation and splitting

I am pretty sure I have a clogged nozzle and the diameter of the filament was 1.68mm. I adjusted the filament diameter setting and did 3 cold pulls. The nozzle seems to be a little better, but it is still coming out at a very slight angle.

All print speed settings are defaulted.

I double checked my slice layer height and it is .2mm. A quick check with my calipers showed .22mm, so I think that is all well.

Re: Layer Seperation and splitting

Debris can jam the filament, and insufficient (or excessive) tension on the filament drive can affect extrusion. Debris jams usually completely stop flow at some point; loose tension screws would cause a continuous slippage.

But the fact the filament isn't sticking together in those really bad cases, implies you need to somehow keep things warmer while printing (enclosure) or turning off the print fan or slowing print speeds a lot.

You say the room has no HVAC - what is the temperature spread over night?