Issue after issue - please help me figure out what wrong

I got my Prusa mk3 kit about a month ago, and within a few hours, I was already printing. This is my third printer, I use Stratasys printers at work and I operate a CNC machine, so im no novice.

at first, everything was great, I printed very complicated models that took up to 15 hours each, and I was super happy with the results.

and then one day the filament sensor burned out, and everything went downhill from there.

Prusa sent me a sensor right away, I replaced it and went back to printing. The first issue was constant clicking from the pully. I tried everything to solve this, but nothing works. I realigned it, I loosened it, I tightened it, I played around with the Z height, I cleaned it - and nothing. it's also worth mentioning that the extruder motor gets way too hot (more than 60 degrees)

At this point, a new issue started, nothing would stick to the surface anymore. no matter how low I would set the Z height, everything would lift right away, tight corners would create a bend (as if the corner is curling on itself). When calibrating first layer height, the square, in the end, will always come out mangled, and at the best of times, it would just lift on both sides.

another apparent issue is the quality of the extrusion - if I lift the Z axis all the way up and let filament pull trough, instead of getting a nice steady stream, it would even curl up and build on the tip, or come out with blobs every 5 mm or so, creating a very inconsistent string.

I tried everything already, I took the entire extruder assembly apart, cleaned everything, checked for any sign of blockage, I calibrated everything like 10 times, I checked the wiring, I tried 4 types of filaments, nothing makes a difference.

At this point im pretty sure the problem is either a faulty extruder motor, or hot end.

Does anyone have any idea? im pulling my hairs here, and im losing days and days of valuable work.

Thank you all!

Tank out

Re: Issue after issue - please help me figure out what wrong

Filament that does not flow straight out of the nozzle typically means there is a blockage in the hotend of some kind- whether it is left over filament from a prior print, or leftovers from a filament change.

I will run some cleaning filament through when I get the nozzle curls, or crank the temp up significantly and try to flush it out.

That will also cause bad first layer adhesion- so I would start there

I assume the clicking happens while printing PLA? This is all too common on the MK3- I had to raise my PLA temps up to 212 and the clicking disappeared. Try raising your nozzle temp 5 degrees and see if it helps and adjust down to where you are happy with it.

Another thing I did was change the PTFE tube inside the extruder to the blue Capricorn tubing- it has a tighter inside tolerance (1.8mm) and is "slicker" than regular PTFE.

If you think the PEI has lost it's "grip" you can use the dry side of a kitchen sponge to very lightly scrub the bed, then clean with IPA.... usually works well.

I hope some part of this helps

Anything can be made better

https://www.myminifactory.com/users/Joe%20Prints

Re: Issue after issue - please help me figure out what wrong

I'm sorry if this does not constitute a solution, but I'd like to add my two cents to this, as some of what you are saying applies to me too.

My filament sensor never worked from the off (got the dreaded 'filament sensor wiring error'), so the calibration wizard would not go beyond that point.

Prusa are sending me a replacement, however, and it didn't stop me doing an 'XYZ' calibration, then doing a first layer calibration so I could get printing.

no matter how low I would set the Z height, everything would lift right away, tight corners would create a bend (as if the corner is curling on itself). When calibrating first layer height, the square, in the end, will always come out mangled, and at the best of times, it would just lift on both sides.

This happened me too. The manual says to increment the z offset (which I know you've done, bear with me), but that if you have to add more than 1mm, then the PINDA sensor needs moving. I found adjustment of the PINDA sensor to be a pain, as it is threaded, and even with the adjustment screw backed right off, you have to apply quite a bit of encouragement to make it move. It then clicks through the threads, and moves more than you wanted. I'd like to see a better adjustment design here.

Nonetheless, I got it to the stage where I could get a good test first layer, even though I still ended up adding .800 to get it to stick, and not produce the problems you mentioned, the rounded corners, and lifting up, etc.

Like you, I then had several great prints, and was very happy. Then I bought some filament from a UK supplier.

Immediately, I had the problems you mentioned (quoted above), and no amount of adjusting would cure them. Another filament from the same supplier was worse. I spent two days adjusting everything I could imagine, including temperatures through a large range, both bed and hotend, different slicer settings, glue stick (helped a little, but should not be necessary for PLA), casting runes, praying to the 3D printing Gods, etc., etc...

At some temperatures, I would get bad stringing, and also lifting up of corners, which obviously ruined subsequent layers, and a few times the whole print would come away from the bed when [n]% finished, which was really frustrating. Other times I had definite over extrusion.

I went back to square one, which was to re-calibrate everything all over again, from the very beginning, and this *did* improve matters, but...

Online searches threw up more than a few people talking about the 'inconsisent extrusion' problems with MK3:

https://github.com/prusa3d/Prusa-Firmware/issues/602

This tied up with some of the results I was getting, although I hadn't cared about it before, as a noob who was happy to get *anything* going at all.

Filament was definitely varying in thickness as it was being laid down, and so logically, all the problems you describe might be connected with this known issue?

I printed a calibration cube, with the aforementioned UK supplier filament, and the far left corner of the first layer lifted (see pic), deforming the print. I let it continue, and I had a layer shift (or something akin to the 'inconsistent extrusion'?) towards the top, which may be seperate issues, but one has to wonder what are the ramifications of this problem towards the top happening on the bottom layer?

I then printed another calibration cube, this time with the silver/grey filament that came with the MK3 kit. The results were superior. The bottom layer was excellent, as far as I'm concerned, and the perimeter round the first layer looks spot on, *except* for the fact that there are some tiny 'bubbles' appearing on the steel sheet.

I found some other posts that say they aren't a major thing, and will go away. They didn't appear to interefere with this print.

There are still some layer inconsistencies. I hesitate to moan, because overall I'm very happy with the machine itself, but have to wonder if these are relevant to the issues I'm having with other filament makes, perhaps exacerbating matters?

I have no idea whether the working filament sensor is going to change things, but it does appear that, in my extremely limited experience, the Prusa filament is consistent/superior to the other batch I bought, which is a major disappointment, because I cannot keep going through the entire calibration process every time I change filament, and *then* try six or seven (or more) times before getting something to stick, and work...

Again, I'm sorry if my experience, and this long explanation, does not throw any light on your issues, but my intent is to get as much information out to other people, whose advice and experience may benefit both of us, and the fact that we're having some coincidental issues made me place my story here under one thread.

G

Re: Issue after issue - please help me figure out what wrong

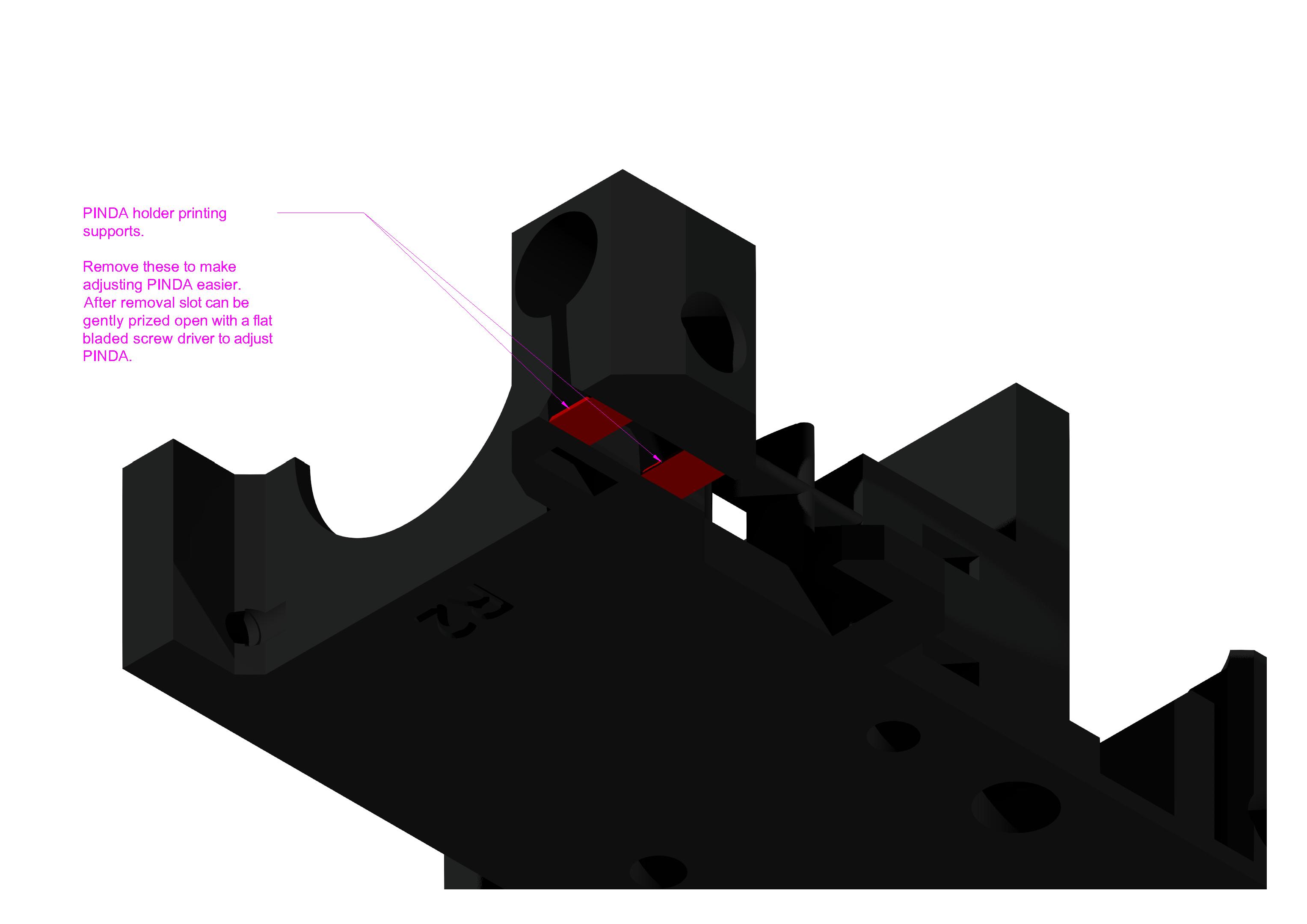

To make adjusting the PINDA easier cut the PINDA holder printing supports. They were only needed when the part was printed and serve no purpose in the assembled E-Axis. Once they are cut and the screw is loosened the slot in the PINDA holder can be prised open for easy adjustment.

Illustration of PINDA Holder Printing Supports

Regards,

Martin

Martin Wolfe

Re: Issue after issue - please help me figure out what wrong

Excellent tip, thanks!