Is this as good as it gets?

Hi Prusa community!

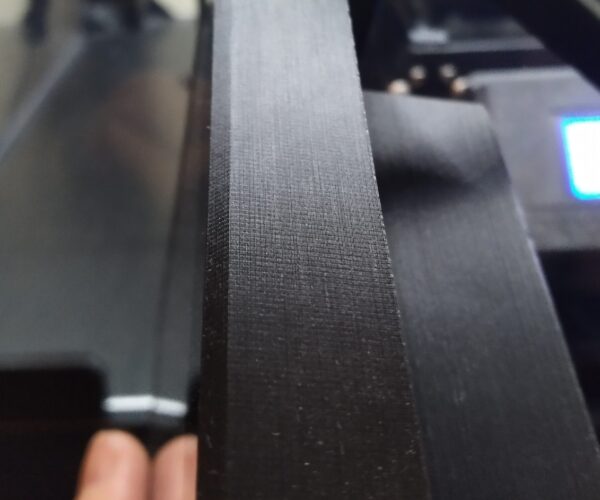

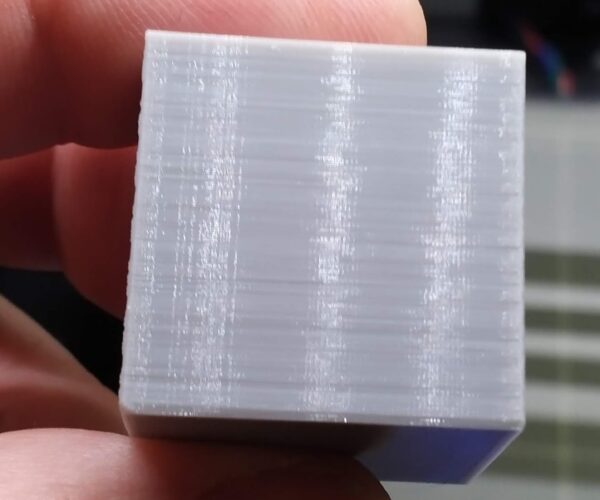

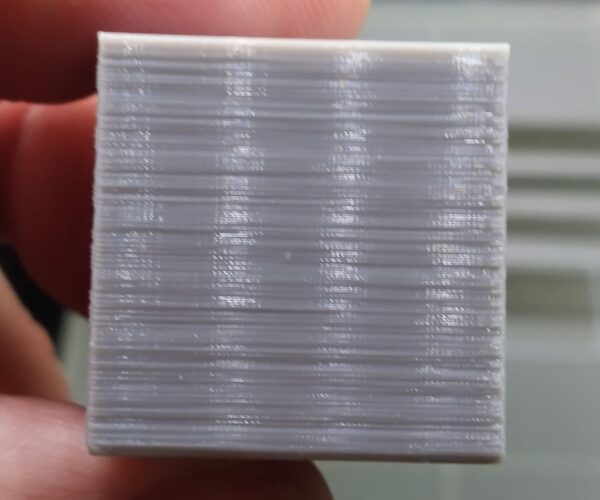

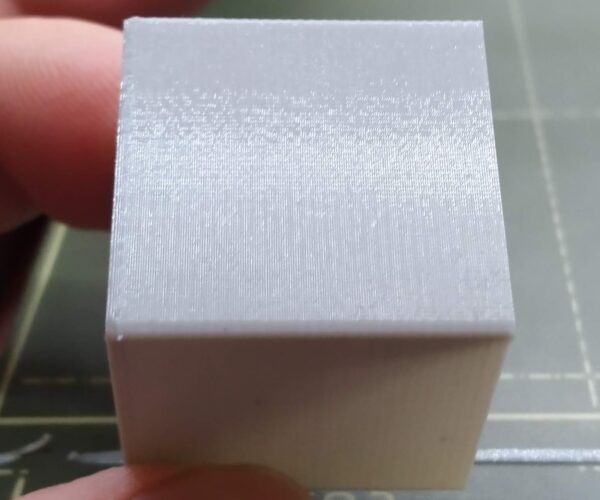

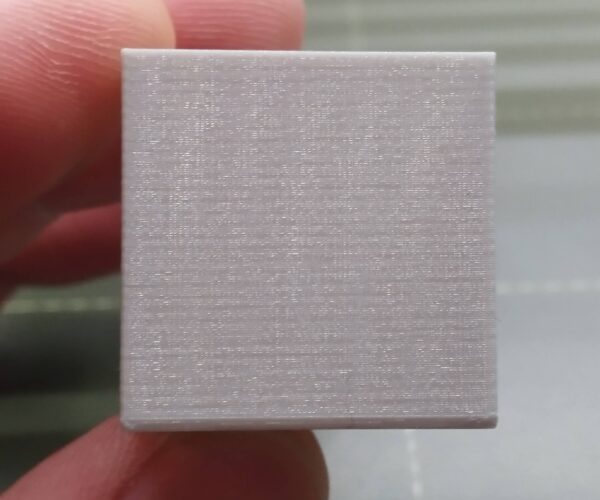

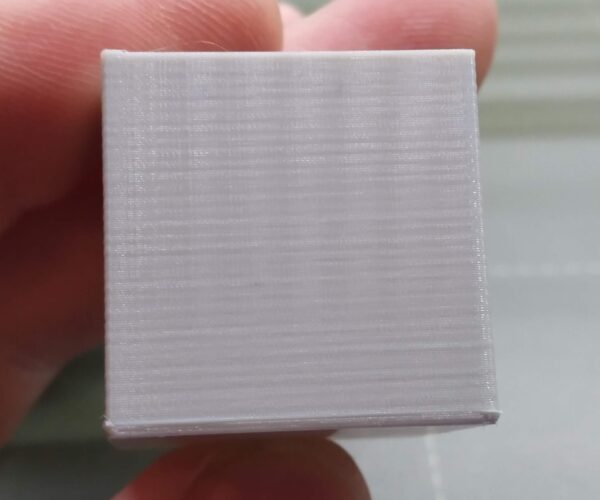

I am feeling a little lost and I was hoping some folks could give me insight. I put together my first MK3s+ about one month ago now and I'm not having the best of luck with my printer. I am getting a strange surface pattern that looks to be related to an inconsistent extrusion of filament - I've attached several pictures of this below.

Here's what I've tried so far;

- I've played with the extrusion multiplier, I even purchased a $100 micrometer to help me take precise measurements of the calibration cube that is listed on the support website and followed instructions. When instructions didn't improve

- I've loosened and tightened the belts - didn't see a huge difference in either direction. Belt calibration numbers x = 240, and y = 271. I did not grease the bearings when I assembled the printer since that was not stated in the manual.

- I've used several filaments. Prusa support suggested after troubleshooting for several hours on the filament used in the calibration cubes that my Jessie filament from Printed Solid was problematic. I've printed with several brands and finishes (matte, silk, regular), all with the same resulting patterns.

- I've greased the rods and checked them for scratches, then I also tried using sewing machine oil a week later after reading more on the topic.

- I switched out my nozzle between the printing of the calibration cubes and the model in the pictures below. Same effective result.

- I've loosened and tightened the screws, which are on the back of the extruder so they're just a little snug.

- I've verified that the extruder gears are properly aligned with the filament.

- I've loosened and tightened the extruder screw that keeps the extruder door shut - at the point of it just catching the screw to a few turns to tighten it more - have not seen much of a change.

- I've verified that all grub screws holding belts/extruder are properly tightened - they were not aligned initially to the flat part of the motor gear when I started troubleshooting this.

- I've slowed down printing to 90, 80, 70, 60, 50, 40, and 30% of slicer defaults - I have not seen much change outside of improvements at very slow speeds (40/30%)

- I've completed a linearity correction calibration, making no changes as I didn't see any improvement outside what was set as a default (I think).

- I've prayed to Josef Průša asking for divine guidance (no response... yet).

- I've printed models at varying layer heights with the same results

- I've recalibrated the axis via the printer menu for giggles

- I've done PID tuning multiple times after hooking up OctoPrint and seeing some isolated 5C temperature variations in prints once.

- I've printed with more walls (6-4)

- I've printed models with 0 infill

You'll be able to see my prints below - am I crazy or is there something wrong here, or is this normal print quality for a Prusa and it's as good as it gets? Now, I'm not the most experienced 3D printer, but I've been printing with an Ender3 v2 Pro for the last couple of years and I can print these same models with the ender without these same artifacts. With that said, the ender 3 is not perfect by any means... but it can make consistent, even, straight lines on walls of the same filaments I used here on the Prusa.

What do you folks think? Thank you for your time and consideration - I really, really appreciate it.

RE: Is this as good as it gets?

You obviously spend a lot of time reading about the usual suspects and tried a lot. Kudos for that!

The answer to your question is: No. That should be much better.

For troubleshooting I‘d recommend to print one of these cubes with default settings 0,2 mm quality with a filament with a provided profile and post a pic.

Additionally, tell us about tour setup. Where is your printer located? Room, environment, enclosure..?

Let’s try to get to the bottom of this.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Is this as good as it gets?

Hi Robin,

Thank you so much for responding. I will do that - what's the best way to export/share a profile? For starters, my printer is located in my office - it runs a solid 70 degrees with about 30-50% humidity. There is no enclosure and very little foot traffic. It's sitting on a relatively stable table, and I have anti-vibration feet attached from this printables object: https://www.printables.com/model/1727-anti-vibration-feet-for-prusa-mk3-and-prusa-mini . I found that these are a little bouncy but they reduce the sound the printer makes a ton. I've printed with and without them, and with the printer on the floor with no large difference between these.

RE: Is this as good as it gets?

Have you dried your filament?

This side is actually getting relatively close to "as good as it gets". The repeating vertical artifacts (search for VFA -- vertical fine artifacts) are due to stepper mechanics and getting to the point where you can see them as the primary surface artifact means that you can tuned the printer very well.

The random surface pattern here looks like a variation in extrusion width. Given the work you have put in and the overall state of the prints otherwise, this makes me think the problem is likely in the filament. Either it is very cheap filament with pretty lousy dimensional quality, or it's wet. If you have filament that is specced at +/- 0.05mm, and actually varies that much, then you have a 6.6% variation in filament diameter. That variation impacts the amount of filament extruded by each step of the extruder and in turn will impact the width of the extruded line. We filament can do the same thing as the water in the filament gets boiled by the nozzle and the pressure causes the extrusion to expand. If it is really bad, you will get very little bubbles, strange rough surfaces, pops and sizzling sounds from the nozzle, etc.

The Ender3 V2 is a Bowden style extruder whereas the Mk3 is a direct drive extruder. That difference if one of the things that leads to those vertical artifacts. The bowden setup allows for enough movement in the filament that slight variations in feed pressure are absorbed by the filament flexing. It inherently keeps to filament extrusion rate more constant (up to a point). This same behavior would smooth out extrusion variations due to changes in filament diameter as well (again, up to a point).

RE: Is this as good as it gets?

Hi Patrick,

Thank you for your thoughtful insight on this. I dried this specific filament once for 24 hours and again for 48 using the v2 Sunlu filament dryer at 50C. I'm using Printed Solid's Jessie PLA - and I don't know if that's considered good. I reached out to Printed Solid to get their take on this and they said for that specific batch, there were no complaints about the diameter... but who knows. I seem to get a lot of conflicting opinions on what is good/vs not good... but it has worked for me in the past, and generally, I've gotten really good results. I've purchased several different brands at this point, including prusament, getting similar results - but honestly, if there's something that helps mitigate these issues, I'll print with it instead - I just need to know what I need to buy.

I recently sat down and spent 6 hours with support trying to determine what could be done about it. After trying what support asked me to do and seeing no changes, they then told me that the prints were normal, which was very frustrating. I mean - why would they have my work on this for 6 hours only to tell me everything was normal?

Feeling super frustrated.... and I'm within my return window for a few days. I'm thinking about just returning it and buying something else, which is such a huge bummer. I really wanted to like this and I need something which can reliably produce prints, but not at this quality. 🙁

RE:

As far as the filament goes, Printed Solid lists it as +/- 0.02mm. Assuming that matches reality, I would consider it fine from a specs point of view. When I've had issues with printing with a filament, its not been the kind of problems you are seeing.

Definitely puzzling. If you don't mind, I'll ask a few more basic questions. Looking at your XYZ cube pictures, it's a little hard to tell -- are the sides equally bad on both the X and Y sides? Is the pattern of the variation reasonably similar on both the X and Y side?

Based on some of the comments in your list of things you've done, I'm going to assume that you built your printer from the kit. Correct?

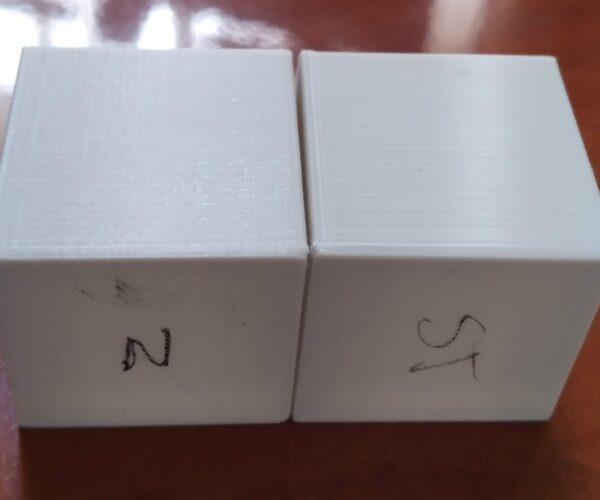

Does the pattern/variation change if you print the cube in a different part of the bed? For example if you print a cube in each of the four corners and one in the center, do they all have the same quality? A simple 1-2cm cube is a sufficient print, it doesn't have to be a full XYZ cube.

If you print 4cm cube in vase mode, with 0 top layers, what do the sides look like?

Are you printing in normal or silent mode?

If you want to rule out the extruder and filament, you can move the extruder up, off the build plate 150mm, then tell the printer to extrude 100mm. You will get a single strand hanging in the air. Once it cools, take the micrometer to it. It should be the same diameter along its entire length. Doesn't really matter what the diameter is, though it should be the same size or slightly larger than your nozzle diameter. You are working at dimensions that are really had to measure, even with a precision micrometer, especially since the filament will deform if you put too much force on it.

Given the smoothness of the variations, it doesn't strike me as a problem with the the axis binding on anything that would cause the motors to skip steps as I would expect those to be sharper, more pronounced deformities. After sitting and staring at my printer for several minutes, the only thing that came to mind is to check all the screws holding the frame together and the Z motors and leadscrew mounts to the frame.

To give you some reference pictures, here are some from my printer. This is the side of a case I did a while back. You can see the stepper drive artifacts in the surface.

You can also see some surface variation. This was printed a good while ago, so I don't know the details around the print right off hand.

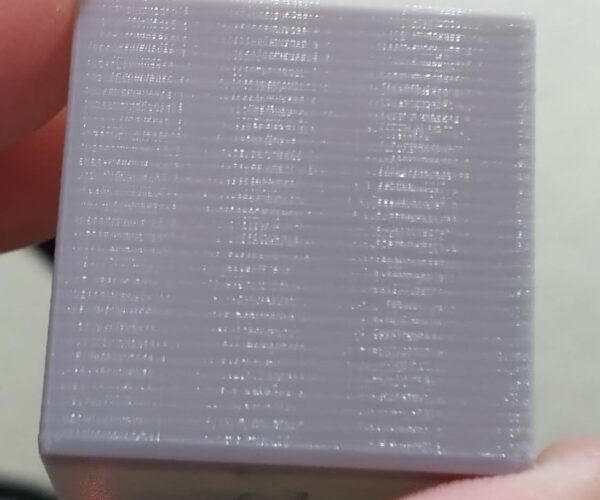

While I was typing this message up, I ran a 25mm cube, using some AnyCubic "engineering gray" that I had laying around. It's been sitting, unsealed for a month or more. 0.4mm nozle, 0.15mm layer, quality setting -- all defaults. I have not done anything other than extrusion multiplier and Z offset calibration on my printer in well over 1500 hours. It just recently finished a print job that was just over 1,368 hours of continuous printing. All that to say, this is a good example of the worst I would expect from a well set up printer.

Looks pretty decent. You can see the stepper artifacts.

What happens when I rotate the face 90 degrees? You can start to see some surface imperfections.

Now I tilt it so the light is at sharp angle to the surface.

Starts to look pretty ugly. You can make out the layer offsets at the sides as well.

In reality, I went to a lot of work to make that picture look bad.

RE: Is this as good as it gets?

Hi Patrick,

Thank you so much for your contributions here... so on your questions:

Definitely puzzling. If you don't mind, I'll ask a few more basic questions. Looking at your XYZ cube pictures, it's a little hard to tell -- are the sides equally bad on both the X and Y sides? Is the pattern of the variation reasonably similar on both the X and Y side?

Yes - the X and Y are both pretty consistent.

Based on some of the comments in your list of things you've done, I'm going to assume that you built your printer from the kit. Correct?

Yes, this is correct.

Does the pattern/variation change if you print the cube in a different part of the bed? For example if you print a cube in each of the four corners and one in the center, do they all have the same quality? A simple 1-2cm cube is a sufficient print, it doesn't have to be a full XYZ cube.

Printing now...

If you print 4cm cube in vase mode, with 0 top layers, what do the sides look like?

You know - I think I recall them looking pretty great when I did the vase-mode calibration cube for the extrusion multiplier. I don't have it, tossed it, but I can print another.

Are you printing in normal or silent mode?

Normal mode.

Given the smoothness of the variations, it doesn't strike me as a problem with the the axis binding on anything that would cause the motors to skip steps as I would expect those to be sharper, more pronounced deformities. After sitting and staring at my printer for several minutes, the only thing that came to mind is to check all the screws holding the frame together and the Z motors and leadscrew mounts to the frame.

They all are snug. Although one thing I recall coming up when I initially put the frame together is that the M5x16r screws appear to be mismatched... maybe? I'm not sure if this would be impactful but some of the screws (10 of them) have some sort of branded element on them, whereas 6 of them do not. They all appeared equal in size to me when I assembled the printer and assumed it was just some variation in hardware since I didn't see any mention of it in the assembly manual.

While I was typing this message up, I ran a 25mm cube, using some AnyCubic "engineering gray" that I had laying around. It's been sitting, unsealed for a month or more. 0.4mm nozle, 0.15mm layer, quality setting -- all defaults. I have not done anything other than extrusion multiplier and Z offset calibration on my printer in well over 1500 hours. It just recently finished a print job that was just over 1,368 hours of continuous printing. All that to say, this is a good example of the worst I would expect from a well set up printer.

Looks pretty decent. You can see the stepper artifacts.

I don't think I need to work hard to get a shot that's not flattering. However, I have white, bright, overhead lighting that illuminates my desk... if I turn this light off and look at it with just my ambient room lighting from other sources it does look better, but I can still make out the texture. I mean - who doesn't look good in the dark though? I know I do. 🙂

RE: Is this as good as it gets?

I ran the same cube in vase mode. Pictures below. Screws coming from different sources wouldn't matter -- they'll all be M5x16 and so long as they all snug down, the origin doesn't matter.

I should note that I am printing in silent mode. I wouldn't think that should matter, for overall quality purposes...

I normal light, might prints have the normal 3d print "shimmer" from the layer lines. At the right angle, I can see the surface irregularity, but only because I know what I'm looking for. Nothing close to the pictures you posted though.

I'm out of ideas for the moment... :shrug: It's gonna bug me though.

RE: Is this as good as it gets?

Hello @patrick-mcnamara -

I’ve been following this thread and totally understand why this bugs you. You’ve invested a lot of time and experience to help the OP and his prints should be improving with all the suggestions you’ve offered.

I’m just curious if it could be a bad nozzle that shipped with the printer? I know this is rare and that users often have issues after swapping out nozzles, but I can’t think of what else is happening here. Interested to hear your thoughts.

Thank you for sharing your insights with the community. I always appreciate members like you who are so generous with their time.

Cheers

RE: Is this as good as it gets?

Hello @patrick-mcnamara -

I’ve been following this thread and totally understand why this bugs you. You’ve invested a lot of time and experience to help the OP and his prints should be improving with all the suggestions you’ve offered.

I’m just curious if it could be a bad nozzle that shipped with the printer? I know this is rare and that users often have issues after swapping out nozzles, but I can’t think of what else is happening here. Interested to hear your thoughts.

Thank you for sharing your insights with the community. I always appreciate members like you who are so generous with their time.

Cheers

Thanks. Having read plenty of threads of people who have little patience or troubleshooting skills, or unrealistic expectations of what is needed to get good prints, when you come across someone like the OP that has done everything "right" and even has a working printer from another vendors, that would be considered "more fiddly", its hard not to share their frustration. It leaves me with the feeling that we are all missing something that will appear quite simple once it is identified, but is odd/strange and therefore not obvious.

At this point, I wouldn't rule anything out. Here is my line of reasoning -- because the imperfections appear pretty random, and affect both axis pretty equally, it is unlikely, in my mind to be something with either axis. It is also unlikely to be something like the axis binding as that would cause pretty major disruptions in the print. Plus, since the OP is printing in normal mode, things that would cause skipped steps would likely be reported by the printer. We are looking for something that could impact both print axis equally and in a seemingly random way. Looseness in the frame, that would allow the overall structure to move slightly as the head and bead moved around could possibly do that. So could a loose nozzle, though I would expect that a nozzle that loose would also be exhibiting other issues, like leaking and/or jams.

@benjiale

What do the rest of the parameters in the support menu look like on your printer. Here are mine for comparison (leaving out the ones that don't impact the physics).

XYZ details:

Y distance from min

Left: 9.50mm

Right: 9.65mm

Measured skew: 0.03deg

[0;0] point offset

X: -0.73mm

Y: -1.00mm

Belt status

X: 237

Y: 285

As a confirmation check, I printed the vase mode cube in normal mode. If anything, it's surface is a bit better.

RE: Is this as good as it gets?

I was suggesting a bad nozzle, not a loose nozzle.

As you say, the OP appears to have gone over all the usual suspects with little to no improvement in print quality. If the nozzle had an internal imperfection or there’s a partial clog in the hotend, it could result in the uneven extrusions we’re seeing.

I’ve had my MK3S+ for about 18 months and a few months back my print quality began to diminish. I did a regular service including lubrication, tightened and adjusted everything, all with no improvement. I decided to change out the original brass nozzle to eliminate it as a possible contributing factor. I installed an 0.4mm E3D nickel plated copper nozzle and the quality returned to normal.

RE: Is this as good as it gets?

Okay, forum timeout ate the rest of my post 🤬

Anyway, I suggest first to slow down a print to 50% using the scroll wheel and LCD menus. Any changes in print quality? If yes, run another print at 70% speed.

If the uneven layers persist at lower speeds, do a couple of cold pulls and try again. If that doesn’t help, I would swap out the nozzle for a new one from E3D. Follow the instructions on the E3D site for changing the nozzle. The Prusa instructions tell you to turn the heat block, don’t! Hold it steady while you remove the old nozzle and install the new one. Be careful as all of this is done with everything heated. Use a 7mm socket for the nozzle and a small adjustable wrench to hold the heat block. Remove the print fan shroud for easier access. Be careful not to touch the heater or thermistor wires with tools.

https://e3d-online.zendesk.com/hc/en-us/articles/360017013257-V6-Assembly-Guide-Edition-2-

Patrick, let me know if you have a different or better course of action at this point. Thanks.

Cheers

RE: Is this as good as it gets?

Hi there Patrick,

Here are the details you're looking for.

XYZ details:

Y distance from min

- Left: 9.78 mm

- Right: 9.58 mm

Measured skew

- 0.01deg

[0;0] point offset

- X: -0.21mm

- Y: -0.71mm

Belt status

- X: 246

- Y: 266

I've not printed the vase mode cube - yet - but I did print the four 2 cm cubes, and there is no discernable difference in either of them, same random pattern. I spent about 6 or so hours with support today with one person coming to the conclusion it's the extruder gears and the other possible issues with the hot end. Both were unable to complete the troubleshooting procedures with me and I'm waiting for an e-mail response from the one technician who asked me to check something basic and he told me he'd 'check back in the new year'. :-/

Regarding the nozzle

I have changed the nozzle from the stock nozzle. I too thought it might be the problem as I noted in my list in the first post I made. These issues were also exhibited using a nickel-plated nozzle from printed solid, which ran me about $15. I saw no change in how this was working. I have too, thought perhaps this might be due to a partial clog, but I've gone through cold pulls, using an unclogging tool, and various other things which clear the nozzle out and reattempt my prints. No dice.

Seeing the problem?

So - I've been taking time to play with slicers (against my better judgment, I paid $59 for the upgrade to S3D v5 because I feel like I've tried everything else) and, I don't think I've eliminated it, but I have seen it, or what I think is it. I turned on the 'print perimeter lines first' setting in PS, and turned off Arcahane perimeter generator (just thought maybe I was getting thicker lines from that generator?). While the print quality hasn't improved from my initial review - I watched the first 15 minutes of the print very carefully and I think I have observed extrusion irregularities with my eyes... when I observed the printer printing the perimeter first, I would clearly see an intermittent thick filament extrusion followed by a very thin extrusion - very thin - almost like stringing... this would then resume regular extrusion about .05-2mm later.

So layer maybe it's layer adhesion? But I have printed temp towers (I checked the gcode changes the hot end temp) from 180 - 240 on filaments and have seen this issue throughout.

Would the spool holder perhaps introduce friction which might cause this? I put it smack-dab in the middle of the printer.

Finally - I checked the gears for proper alignment with the filament, the grub screw holding the gear in place, ensured they were cleaned, and applied a small amount of grease. I've tested very low, low, medium, and high levels of tension on the tensioner door.

So not sure... temperature related?

RE: Is this as good as it gets?

Here’s the Prusa instructions for a nozzle change. It looks like they have updated them and removed the bit about turning the heat block.

https://help.prusa3d.com/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

Cheers

RE: Is this as good as it gets?

Hi,

Anyway, I suggest first to slow down a print to 50% using the scroll wheel and LCD menus. Any changes in print quality? If yes, run another print at 70% speed.

In my initial post I said I had tried this already;

I've slowed down printing to 90, 80, 70, 60, 50, 40, and 30% of slicer defaults - I have not seen much change outside of improvements at very slow speeds (40/30%).

The quality issues though, I saw improvements in were ghosting of artifacts - and not necessarily ones related to this odd texture. I have printed fast, too - I saw a video about VFA where they said you need to go 50% faster on perimeters... no improvement in this texture issue.

RE: Is this as good as it gets?

Hello @benjiale -

I must have missed where you changed the nozzle so please ignore my prior post(s). I also see you’ve done multiple cold pulls.

Have you tried printing different materials and do the uneven extrusions occur with all materials? Definitely a strange one.

Cheers

RE: Is this as good as it gets?

Apologies, I guess I need to go back to the start of this thread and reread your posts…

Hi,

Anyway, I suggest first to slow down a print to 50% using the scroll wheel and LCD menus. Any changes in print quality? If yes, run another print at 70% speed.

In my initial post I said I had tried this already;

I've slowed down printing to 90, 80, 70, 60, 50, 40, and 30% of slicer defaults - I have not seen much change outside of improvements at very slow speeds (40/30%).

The quality issues though, I saw improvements in were ghosting of artifacts - and not necessarily ones related to this odd texture. I have printed fast, too - I saw a video about VFA where they said you need to go 50% faster on perimeters... no improvement in this texture issue.

RE: Is this as good as it gets?

Have you tried printing different materials and do the uneven extrusions occur with all materials? Definitely a strange one.

I have observed this while printing PLA (and variants like Plus, Meta, and whatever manufacturers market their stronger PLAs as), abrasive PLAs (glow-in-the-dark, wood texture), matte PLA, glossy PLA, silk PLA, glitter PLAs, and various colors of the Jessie PETG. I have tried alleged awesome brands to bargain basement junk. I store my filaments in a Rubbermaid gasket-lined box which has one of those plug-in desiccant dehumidifiers, then I seal them in vacuum bags with desiccant until use - where I typically run them out of a dryer - something I've not been doing with the Prusa since I've not devised a good way to accomplish that yet (I have a printed rack addon for my other printer). I can say that some of the PLAs mask this issue better than others simply because they reflect light differently, but I have still observed the same pattern and inconsistency.

RE: Is this as good as it gets?

I'm not sure if I was clear enough about this and I can't seem to edit this now - but I feel like I expressed I saw this only once. I saw this several times - usually once every 1-3 layers in different spots.

Seeing the problem?

So - I've been taking time to play with slicers (against my better judgment, I paid $59 for the upgrade to S3D v5 because I feel like I've tried everything else) and, I don't think I've eliminated it, but I have seen it, or what I think is it. I turned on the 'print perimeter lines first' setting in PS, and turned off Arcahane perimeter generator (just thought maybe I was getting thicker lines from that generator?). While the print quality hasn't improved from my initial review - I watched the first 15 minutes of the print very carefully and I think I have observed extrusion irregularities with my eyes... when I observed the printer printing the perimeter first, I would clearly see an intermittent thick filament extrusion followed by a very thin extrusion - very thin - almost like stringing... this would then resume regular extrusion about .05-2mm later.

RE: Is this as good as it gets?

Went back to the top and reread your original post and I see where you’ve done everything I suggested and more.

I recall reading in another thread where someone had a similar problem and it was discovered that something was loose in the extruder/hotend and it was ‘wobbling’ during printing.

With the hotend at room temperature, if you grab the nozzle, can you move it left, right, forward, back, or any other way? Do you notice any movement of the hotend while printing?

I’m afraid I’m not being super helpful here 🫤

Cheers