Inconsistent Extrusion

Hi all,

every print went fine on my MK3. No matter of filament.

But out of a sudden I ran in a problem of inconsistent extrusion.

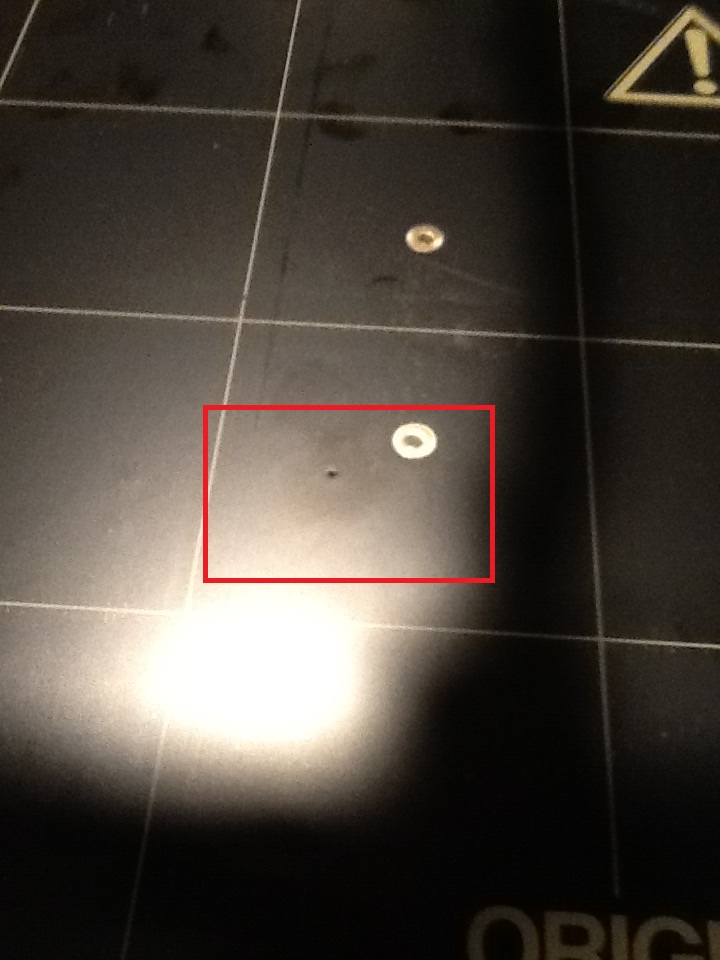

The pictures show the ramming line

and a skirt line

No print is possible any more, because the lines don't stick to the bed because of repeating underextrusion.

Sometimes (very seldom) the extrusion motor skips back.

I tried allready:

- different filaments: PLA, PETG, filements out of my box with drying pearls, brandnew filament

- cleaning the nozzle

- new nozzle

- disassembling, cleaning and reassembling of the hot end => no reasons can be seen

- different spring loads on pulley

- different Z-calibration

Has anyone experienced the same? Any ideas to fix this?

Günter

Re: Inconsistent Extrusion

That isn't under extrusion - your Z height is way too high.

Re: Inconsistent Extrusion

THX for looking at this.

I calibrated the z-Axes once more.

Then I found a posting, where the filament sensor got hot and caused inconsistent extrusion.

I unplugged the filament sensor and the next first layer was (allmost) perfect.

But the second layer (higher speed) didn't print at all (underextrusion)

I did another print (see picture) with higher temperature.

Please take a look at the ramming area. In the past there was much more filament.

The skirt: incomplete.

The numbers show the sequence of printing. On 4 surface incomplete.

On 3 and 5 one of the two lines of the circle incomplete.

Any new ideas?

Günter

Re: Inconsistent Extrusion

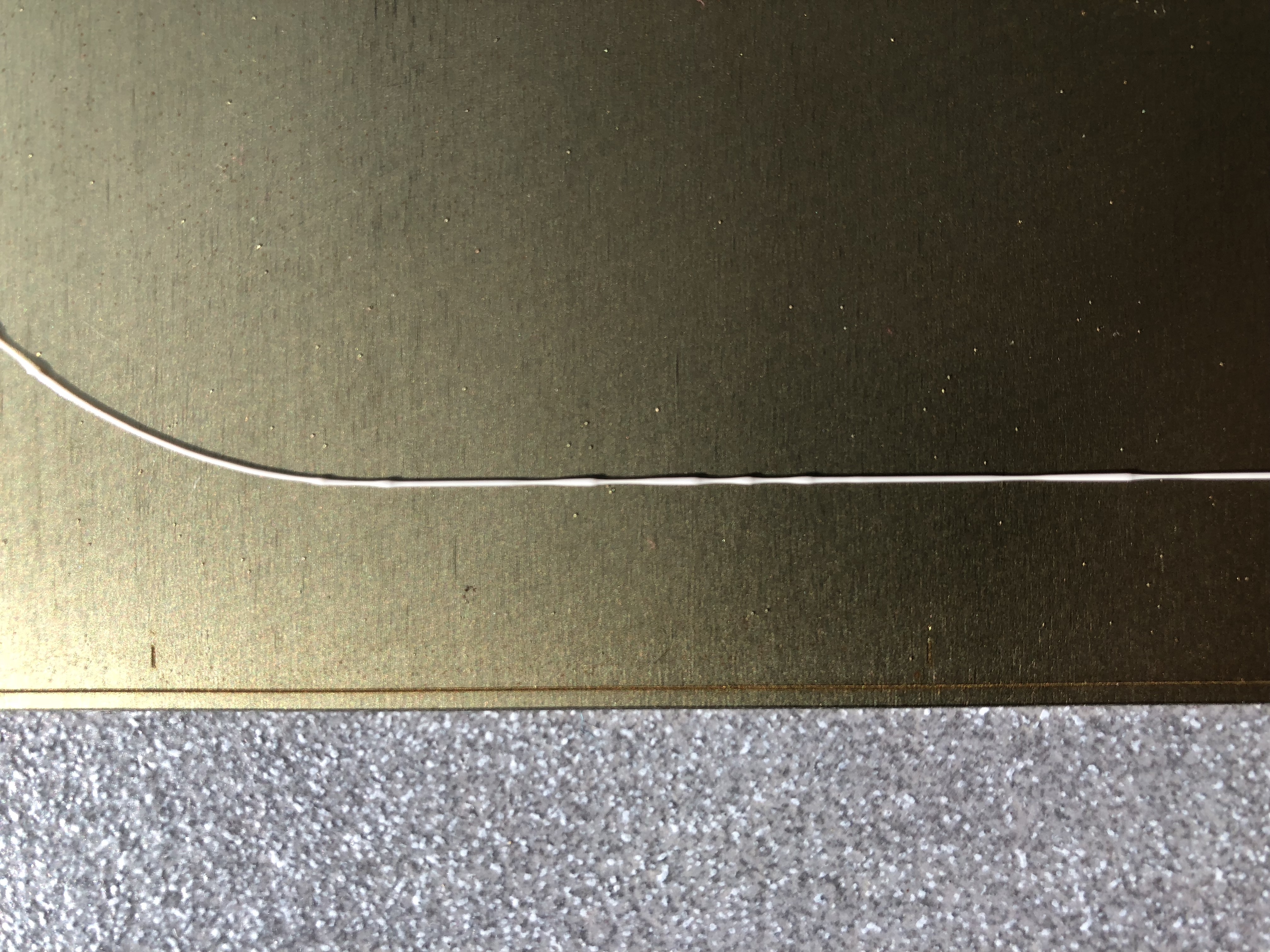

'Did a print of "MK3_PLA_Prusa_200um_19M.gcode" to eliminate all variables due to the slicer.

Ramming: OK

Skirt: OK

First Layer: OK

Further layers: see picture. Extrusion motor clicks and skips back constantly (that's new)

Re: Inconsistent Extrusion

This looks like extrusion issues, the "inconsisten extrusion" is something else though.

Possible causes based on my (moderate) experience:

Partially blocked nozzle: do some cold pulls or change nozzle (hot!)

Bondtech gear tension: check that the gears are not too tight and not too loose. They should just grip the filament, but not more.

I think overheating can be ruled out, since this is a PLA only issue and you had problems with PETG as well. Nevertheless it's better to keep the ambient temperature lower with PLA, to avoid it getting stuck in or before the heat brake.

I've hads something similar and it was the Bondtech gera tension, but I also learned to do cold pulls 😀

Good luck and report back!

Re: Inconsistent Extrusion

Make sure your filament spool moves freely also.

---

Gert

Re: Inconsistent Extrusion

Hi out there,

I did two cold pulls. And now it prints like the first day.

(But don't ask me, how this kind of issue could survive a nozzle change - maybe two issues at the same time)

Because still to be tested: a print with filament sensor.

Stay tuned!

THX to all for good advice.

Günter

Re: Inconsistent Extrusion

Hi to all,

back again after 10 days of testing different prints ...

PLA printed fine. But I had further issues with PETG:

During fast moves there wasn't enough filament. (eg at infills).

But this issue is solved allready:

The nozzle was absolutely tight while it was cold.

But when it was hot, it was a bit loose.

So my to do for nozzle changes in the future: tighten it cold, heat up, tighten it again.

Günter

Still not tested: a print with filament sensor.

Re: Inconsistent Extrusion

Actually nozzle changes always have to be done with a heated hotend.

Trying to unscrew a cold nozzle will easily destroy your heater block and as you experienced, tightening a nozzle in the cold heater block will lead to leaking.

Also use a tiny amount of copper paste on the thread to prevent the threads from sticking. That paste is designed for scews used in hot areas, like the engine exhaust manifold on your car. Buy at car parts shop for little money. It will make removal of the nozzle easier.