I cannot get the powder coat sheet to print correctly

I have tried numerous times to get prints to work with the powder coat sheet and they just will not stick. I have recalibrated every time. My flat sheet calibration is at z=-0.85 and the powder coat appears optimal at about z=-1.0. It will calibrate. When I try to print something I always end up with significant first layer issues with things not sticking, or the first few layers will stick but after about 10 layers stuff is falling off and the print ends up failing. Any tips would be appreciated.

RE: I cannot get the powder coat sheet to print correctly

All with PLA, I'm guessing? I've had great luck with TPU and PETG sticking just fine to the textured sheet, but ongoing adhesion issues with PLA. The smooth sheet is amazing for PLA.

Some advice I have tried, with limited success:

- The "life adjust Z" post here is better for levelling -- this is a good idea for both sheets and regardless of any issues you may have Life Adjust Z

- If you're finding the adhesion problems are more in certain parts of the bed, you can try Bed Level Correction or the Nylock mod

- Increase bed temperature to 70 degrees for PLA

- Wash the textured sheet with unscented dish soap and hot water

- Go nuts with the isopropyl alcohol cleaning... pour some on there and let it soak a few seconds before wiping with a clean paper towel

RE: I cannot get the powder coat sheet to print correctly

On the textured sheet, I have to smash PLA a bit more than recommended, and I always use a brim - even then I would have imperfections on the 1st layer, but almost always good enough for a finished part.....but nothing I would consider better than "prototype" finish. I honestly hate PLA without the smooth sheet....but they have been removed from the store currently due to the pandemic.

My steps are clean with ISO before printing, use 60C Bed, Brim, and enough smash to have a prominent elephant foot.

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: I cannot get the powder coat sheet to print correctly

Hi Evan,

Did you do all of those at the same time? Lol...

Hi rimcrazyph,

The textured print bed seems to be problematic for some folk.

Please give these notes a try, without adding any extras (No IPA, NO Acetone, no Glue, No ABS juice, No Hairspray, No Painters tape), and if it doesn't work after giving this process a fair try, then... I am out of options, guess you will have to try other options...

I assume you are having problems with PLA, make sure there is a roll of PLA, properly loaded in the printer before you start.

1, Make sure your printer is using 7x7 Mesh Bed Levelling,

2, Download the Zipfile from the first post on this thread>>> https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

Unzip the file and copy the appropriate file to your SD Card there are files for PLA, PETG, ABS.

3, If you have been printing abrasive filaments with a brass nozzle, change your nozzle to a new 0.4mm nozzle just to ensure your nozzle is not worn out.

Make sure that any previous surface preparations have been fully removed from the textured build plate surface

4, take your build plate off the printer and into the kitchen

5, using hot water and fairy liquid (or equivalent dish detergent) and a clean scotchbright/ foam kitchen pad, scrub the build plate surface vigorously, from side to side, then from top to bottom, then diagonally working from the top left corner to the bottom right corner, then diagonally from the top right corner to the bottom left corner, then scrub in circles. (if you can think of other ways to scrub it, to make absolutely sure the surfce is clean and grease free, give them a try too!) and finally rinse off the soap suds using clean HOT water, handling the build plate by the edges, drain and shake off excess water and dry the top and bottom surfaces well, with a clean paper towel,

Install the build plate back on the printer (ensuring that no foreign bodies are left between the build plate and the heatbed, and

6, start the print using the appropriate Gcode file, that you loaded on the SD card, earlier.. (Be aware that the printer will initially heat to 160C before completing the Mesh bed levelling, then It will heat to the proper temperature for the print. )

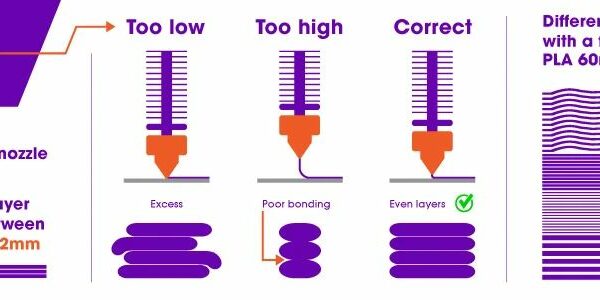

7, as the print progresses, adjust the live Z values to obtain a nice smooth layer with all of the lines of filament squished enough to join with the adjacent lines, with no gaps, no ripples and no surface roughness.

when you lift the test square off the buildplate (Without rubbing your fingers across the build surface), the square should ideally be a single smooth layer of plastic, with all lines of filament weldedmfirmly together.

If the lines of filament are like separate straight lines of spaghetti, the live Z value is toosmall a negative number

If the lines are welded together but buckled to form ridges and possibly a rough surface, then your Live Z number is too big a negative number.

If the test patch is a single sheet with barely visible straight lines welded together with a smooth surface, then your live Z is just right

you may have to try the test squares a number of times. the amount of 'squish' required may be more than you expect, on the textured build plate. Please note, you should never need a positive live Z value, ever!...

You may wish to try 70C for the Bed temperature for PLA...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: I cannot get the powder coat sheet to print correctly

Thanks for all of the recommendations. No PLA at the moment I'm using Prusament PETG. Will not stick for the life of me. Was actually trying to print the RC3 Headshield. I have tried using the textured sheet before with no luck. Thought I'd try again this morning and would just not work. I always use the 7x7 level before any print. I will look into the Life-Adjust-Z-MyWay. Thanks for the tip. I do a super clean too all be it really has not been used at all.....well because it won't print but I'll clean again. I know not to use acetone on it. I use isopropyl wipes...lots of them for cleaning.

RE: I cannot get the powder coat sheet to print correctly

That's quite odd,

Some people complain that PETG adheres too well...

anyway, give it a try with Soap and water, cross your fingers

try a print,

and GOOD LUCK!

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: I cannot get the powder coat sheet to print correctly

That's quite odd,

Some people complain that PETG adheres too well...anyway, give it a try with Soap and water, cross your fingers

try a print,

and GOOD LUCK!Joan

LOL.... I always knew I was strange...Guess this proves it. I'm using the default Prusament PETG print profile. I also tried doing a 10 min preheat before a print just to make sure all of the temps were stable but still no luck. I will try all of your suggestions. My guess is most likely it's calibration and uber clean first and maybe tweaking the temp next. All good feedback so I will go from there. Did not know about the Life adjust z so that's a good thing too I'm sure.