RE: Help understanding calibration issues

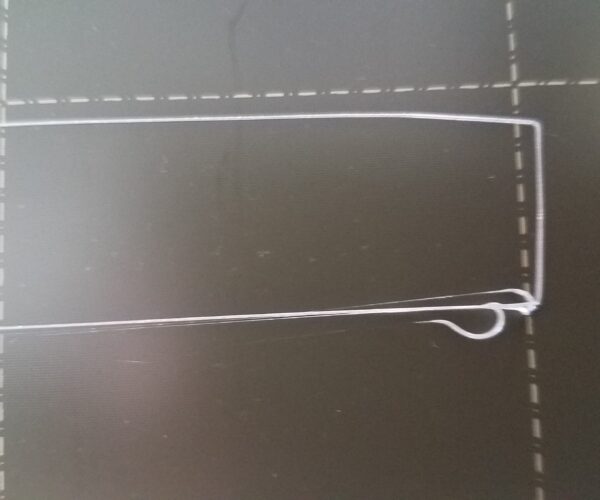

That looks like the nozzle is still too high,

Try this link

the Life Adjust 'Z' process is easier to understand.

Please note that you can change the Live 'Z' value, during a print...

I think your live Z value needs to be a bigger"Negative Value"

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Help understanding calibration issues

@joantabb

Wow, thanks, that really made a difference!

I did that adjustment before, but I was afraid to adjust too much, setting it to -0.015 or -0.020 but never saw any change. After your diagnosis I thought hell, lets go all the way and set it to -1.000. It really made a difference. Is -1.000 or greater a typical adjustment amount?

RE: Help understanding calibration issues

@jconallen

Hi, Over the years the 'acceptable range, has changed. the preferred range used to be 0.300mm to 0.750mm , Now I think it's up to 01.900 to be honest I am not keeping an eye on that as it's a while since I last built a printer.

the situation is, that,

the smaller the negative Live Z number, the bigger the differential between nozzle height and Pinda Probe... (This is good... in that it minimises the chances of a collision between the Pinda, and a warped part on the heatbed...

the Bigger the Negative Live Z number, the smaller the differential, between the Nozzle Height and the Pinda Probe. (this is not so good...)

All of my printers have different Live Z values, the Mk3 next to me as I write, is running a powder coated build plate, and the Live Z is over 1.000, if I put a Smooth Build Plate on the printer this live Z needs to be reduced, because the PEI Sheet and adhesive layer, are together, thicker than the Powdercoat film.

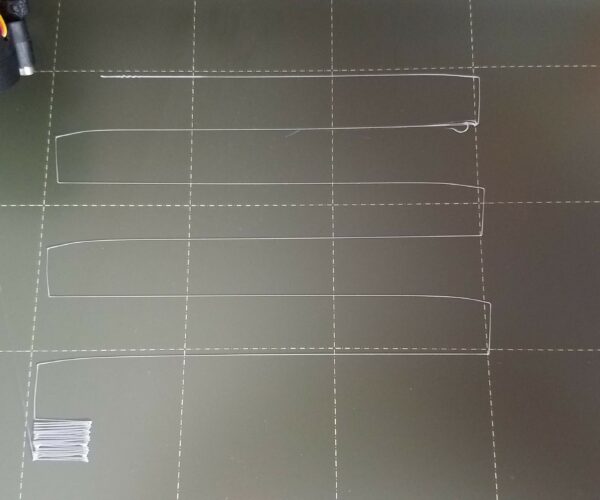

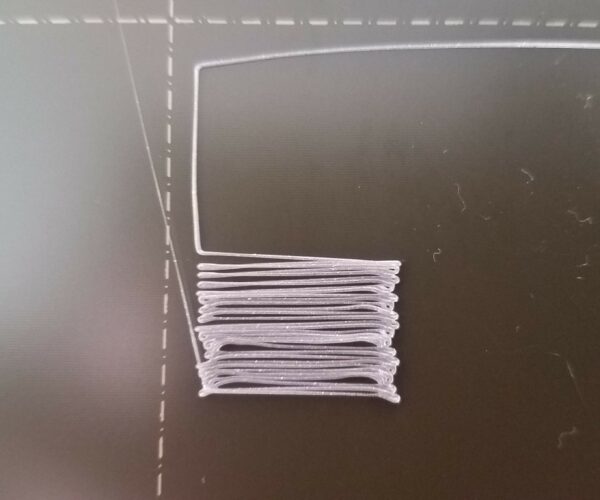

Can we see a photo of your first layer?

if the patch seperates into strands, as it is peeled off the build plate, then Live Z is still too high.

If the patch stays together as a single sheet and is smooth on the top side, you are just about correct,

If the patch has a rough top surface and / or has ripples in the surface, and the strands are welded into a sheet, you have gone too far...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK