HELP - Prints failing after using ABS

Hi everyone,

I set my new Mk3 up last week, went through all the configuration settings, and was making some fantastic prints. Once calibrated, the Mk3 was printing amazingly well!

Then, yesterday I tried to make a print using ABS (had been using PLA up till then). It was a print I've done before on another machine, but the print failed 3 times yesterday, so I gave up until I have more time to fine tune my ABS settings. I then ejected the filament and replaced it with PLA.

And that's when the problems started.

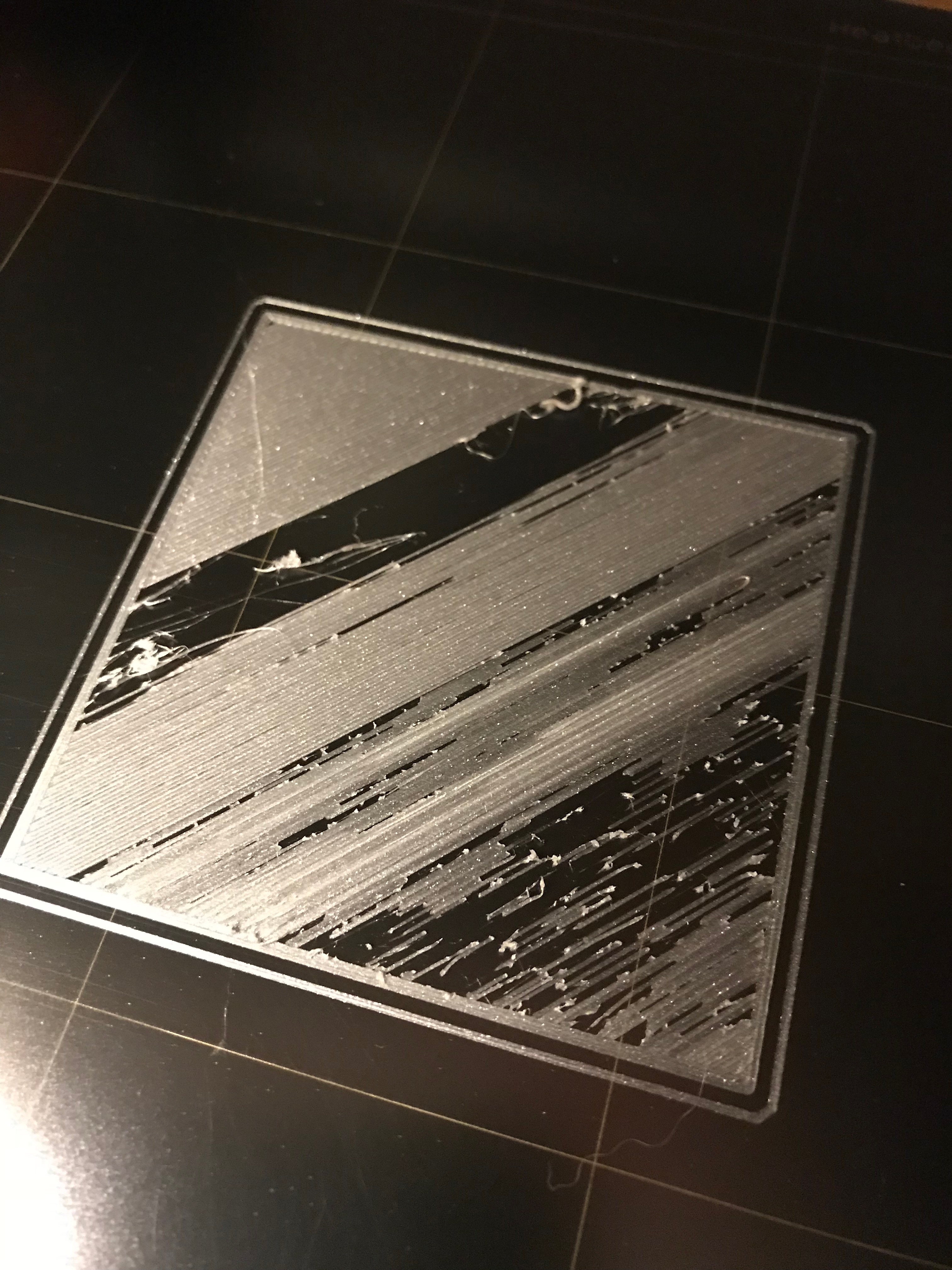

Now when I print, I get massive swaths of nothing or what looks like the print is being scratched (see picture below). The places in the photo where the print is smooth and good, is when I've paused the print, raised the extruder, and poked the acupuncture needle up it several times. Then it prints OK for 20-30 rows, then starts failing again.

Also, at the points of failure, there is a clicking sound where the rollers are trying to push the filament through, but it's not moving. The sound is of the rollers skipping on the filament and the filament springing back up.

I have run 3 or 4 of these 75x75mm calibration prints, and have double checked that the Z axis fine tuning is set correctly. As you can see, when I've cleaned the nozzle, it prints fine for a bit.

Is there a way of super cleaning out the nozzle, to make sure nothing is stuck in there? I have heated it to the ABS temps, and used the acupuncture needle several times. Have probably used the needle 20 times or so now in total.

Unless you guys can give me some good advise, my next step is to dismantle the extruder and make sure everything is as clean as can be, but don't want to do that if I don't have to. Besides, I think the problem is inside, and don't know the best way to clean it out.

Thoughts?

Re: HELP - Prints failing after using ABS

Now when I print, I get massive swaths of nothing or what looks like the print is being scratched (see picture below). The places in the photo where the print is smooth and good, is when I've paused the print, raised the extruder, and poked the acupuncture needle up it several times. Then it prints OK for 20-30 rows, then starts failing again.

Check for debris under your steel build plate. It looks to me like there may be areas where the nozzle is getting too close to the plate on the first layer, which would cause the symptoms you describe. If you have a little bit of plastic or other stuff trapped between the heated bed and the steel build plate it can cause it to lift just a bit. It doesn't take much.

Re: HELP - Prints failing after using ABS

It's hard to see at your picture, but I think your Z level is a little bit to low.

In addition, you should clean the bed with warm water and detergent. It is significantly better than either alcohol or acetone.

Bear MK3 with Bondtech extruder

Re: HELP - Prints failing after using ABS

Have checked that. I remove the plate after each use and clean it well, and then check the heat plate for any debris.

I've experimented with different Z settings, and it prints fine after I needle the nozzle. I'm 99% sure the z height is good. and that wouldn't explain the clicking noise in the extruder.

But, worth raising the Z up a bit and starting from scratch. I suppose if the Z was too low, and it couldn't push the plastic onto the plate, that would generate the same issue.....

Testing...

Re: HELP - Prints failing after using ABS

Yes. Whenever you go from high-temp to low-temp materials, it's recommended to use the cold-pull method to clear the hotend and nozzle of any accumulated high-temp materials. Repeat as necessary until the cleaning filament comes out clean.

[...] Is there a way of super cleaning out the nozzle, to make sure nothing is stuck in there? I have heated it to the ABS temps, and used the acupuncture needle several times. Have probably used the needle 20 times or so now in total.

Before you start, you can confirm you've likely got a partial block by raising Z to max, heating up to print temp and extruding filament. If it doesn't come out smoothly in a straight line (after removing any snags), you may have a partial hotend or nozzle clog.

I recommend doing a cold pull anytime you switch materials of different characteristics, or before a nozzle swap. You want to avoid having any high-temp stuff stuck before trying lower-temp prints.

I'm a fan of cleaning filament although others swear by using white ABS the same way.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: HELP - Prints failing after using ABS

I took the Z setting back up to -0.300 and started the print. It printed smoothly, and didn't make the clicking sound. So, maybe the Z height was the issue.

I increased the Z setting by 50 every few minutes through the test print, have just started the 2nd test at -0.450. The print strands aren't sticking together yet, so going to work my way back to -0.500 to -0.550.

Thanks for the advice.

Must remember, always go back to the basics when there is a problem.

1. check build plate

2. check calibration

3. check temperatures

Thanks guys 🙂 Feeling much less frustrated.

Re: HELP - Prints failing after using ABS

WANTING TO SCREAM NOW!

What am I missing?

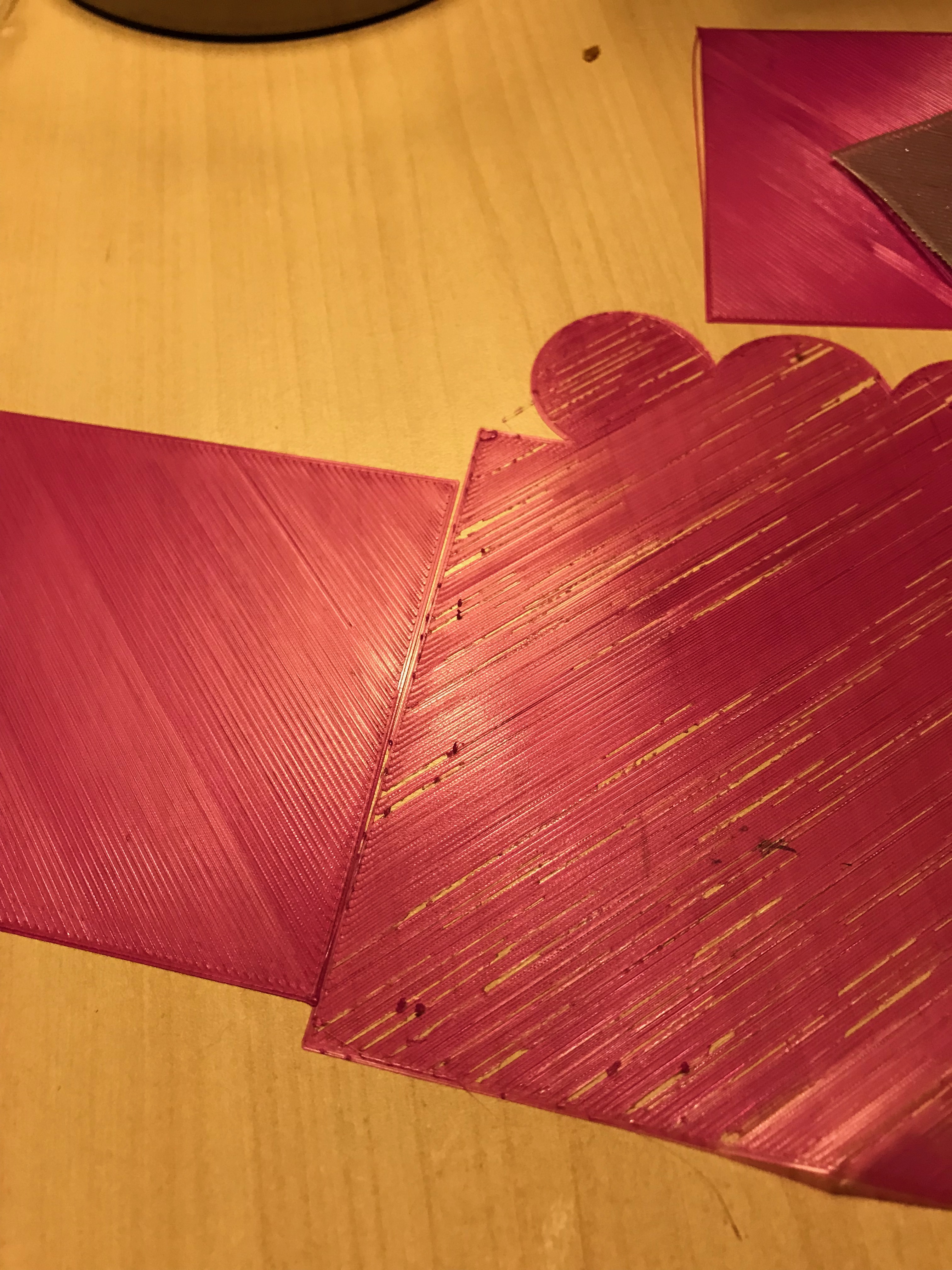

I've run 4 calibration prints as pictured below. From the top left print, I started at -0.300, and increased it by -50mm until the bottom right print, which is at -0.650. Everything printed fine, no clicking, no skipping.

So, thought I had found and solved the problem, and that problem was Z calibration. I even noticed a little piece of the red ABS came out during the print. WooHoo!

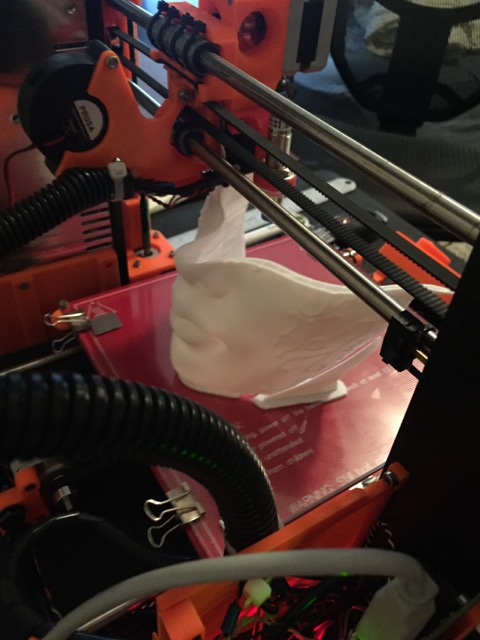

So, then I went on to a proper print, and this happened.

It would print a few lines Ok, then skip and clip, and print, and skip and click.... When it went to layer too, it started printing at a 90º angle from the first layer, and much faster. As you can see, nothing of the 2nd layer printed, and that's when I aborted.

So now I'm chilling out, resisting the urge to scream at my new printer, also resisting the urge to power up my old printer so I can at least print something.

Thoughts?

Re: HELP - Prints failing after using ABS

I've run 4 calibration prints as pictured below. From the top left print, I started at -0.300, and increased it by -50mm until the bottom right print, which is at -0.650. Everything printed fine, no clicking, no skipping.

So, thought I had found and solved the problem, and that problem was Z calibration. I even noticed a little piece of the red ABS came out during the print. WooHoo!

So, then I went on to a proper print, and this happened.

It would print a few lines Ok, then skip and clip, and print, and skip and click.... When it went to layer too, it started printing at a 90º angle from the first layer, and much faster. As you can see, nothing of the 2nd layer printed, and that's when I aborted.

So you have to ask yourself what's different between the test prints and the real print. One thing that's obviously different is that you're using different filament. It may also be trying to print a little faster because there's more room to accelerate on the straight line infill.

To me, the picture and symptoms you're seeing in the real print looks like it could be caused by either too low of a print temperature, or trying to print too high of a volumetric flow rate (the two are related: a higher temperature will let you get away with a little higher print speed).

I'd suggest double-checking that you're using the right filament profile, and bumping the print temperature up a few degrees and/or the volumetric flow rate down a bit. See if that helps.

Re: HELP - Prints failing after using ABS

Hi Peter,

Same filament on both sets of prints, just the light and background was different in the photos.

I was thinking along the same lines - what has changed between the 2 prints? And it comes down to the parameters of the gcode. I'm going to load them up in the morning and see what is different between them. The calibration prints were quite slow. The print job was set to 'fast', as it's a big print.

That's a good thought about adjusting temperature for different print speeds. Will do more testing in the morning, try some basic prints at a slower speeds, then hotter temps and faster till I find the right mix.

So frustrating, as it was working so well.

Renee

Re: HELP - Prints failing after using ABS

Same filament on both sets of prints, just the light and background was different in the photos.

Really? Daaaang!

I was thinking along the same lines - what has changed between the 2 prints? And it comes down to the parameters of the gcode. I'm going to load them up in the morning and see what is different between them. The calibration prints were quite slow. The print job was set to 'fast', as it's a big print.

That's a good thought about adjusting temperature for different print speeds. Will do more testing in the morning, try some basic prints at a slower speeds, then hotter temps and faster till I find the right mix.

If the prints were running at substantially different speeds, then I suspect that's your answer. Slow it down and see if that fixes the problem.

Re: HELP - Prints failing after using ABS

Really? Daaaang!

I know, right! Flash backs to 'do you see a blue dress, or a gold dress?' LOL

Re: HELP - Prints failing after using ABS

Making progress on this problem.

I started by cold-pulling the filament out twice, until it came out cleanly.

Then, I opened the side of the Extruder and swung the idler up and out of the way. I noticed that the pulley was ever so slightly off centre from the filament (sorry, no picture). But it was off by may 0.25mm, if that. Just barely noticeable. So I loosened the lock screw and centred it on the filament. I then reassembled the extruder compartment, being careful to ensure the spring loaded M3x40 screws were tightened the same.

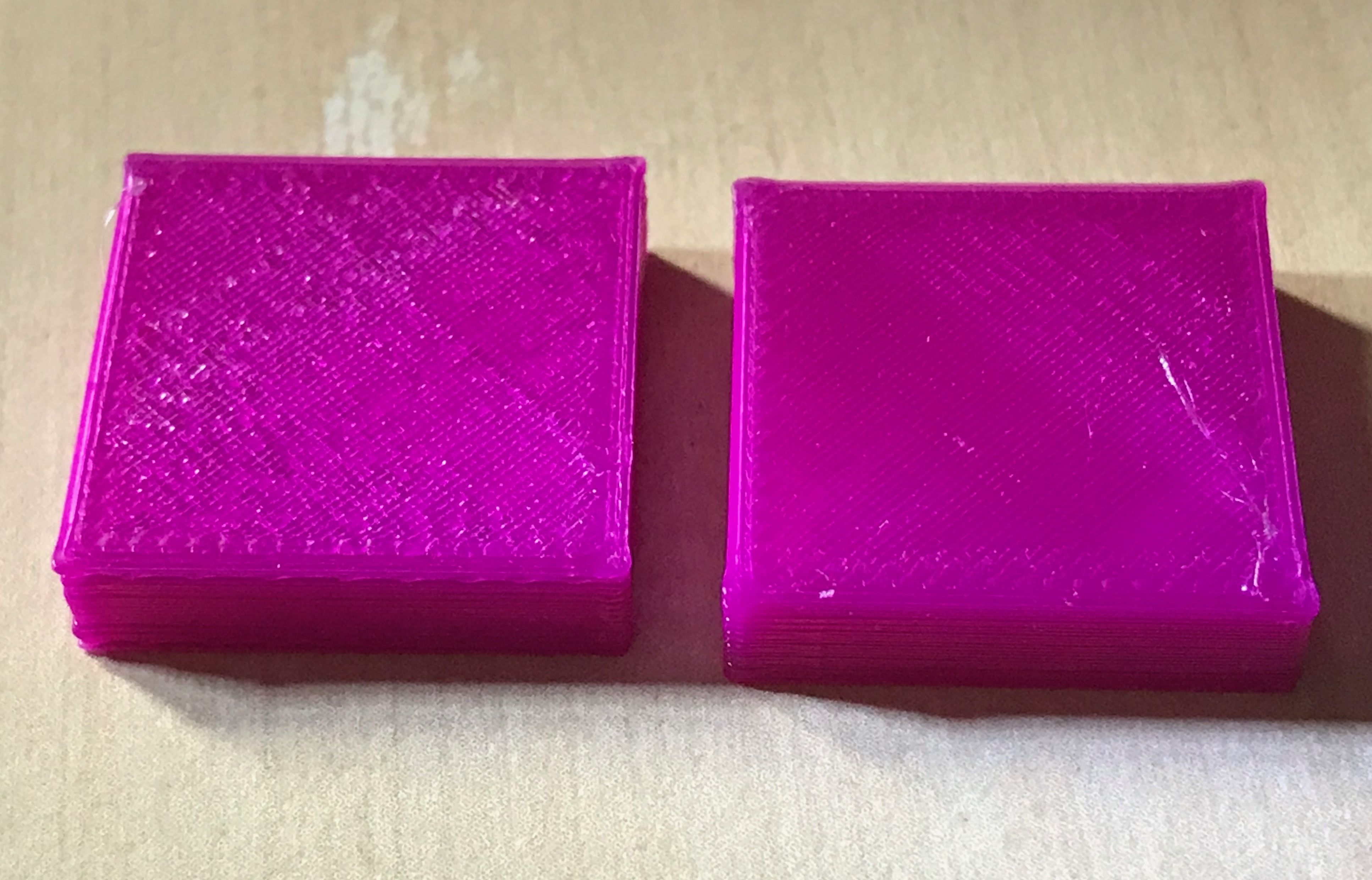

I then recalibrated the z axis with 2 calibration prints, that went fine. I did a test print of some small boxes on ULTRADETAIL setting, and they printed great.

I then printed a 20x20x5mm box on FAST speed. It printed Ok, but there was occasional clicking, but not as loud as it was before. I paused part way through and tightened the spring loaded screws a little, which seemed to help a little.

I then re-printed the 20x20x5mm box, but I slowed the infill speed down from 200 to 150, and set the max print speed to 150. And it was MUCH better.

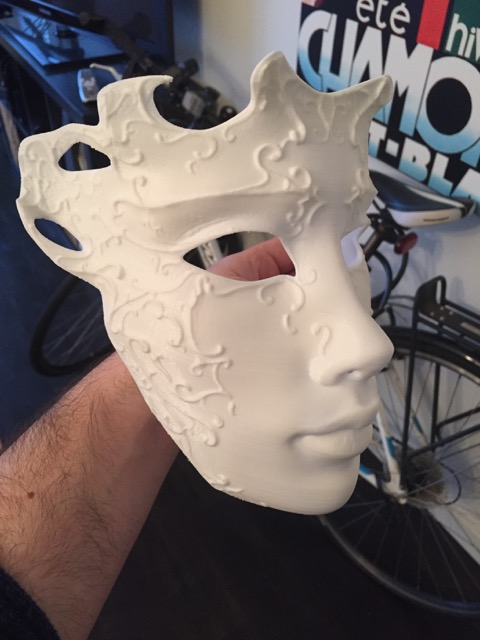

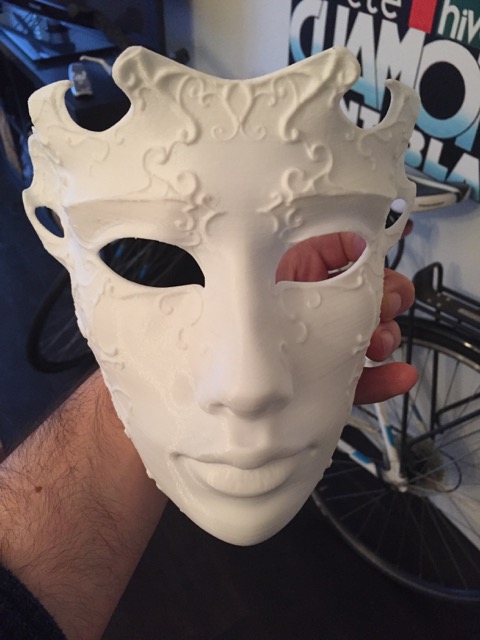

The box on the left was printed with infill and solid infill at 200, the box on the right it was printed at 150.

They look pretty similar, but when you rest them onto of a Maglite, you can see the difference.

Speed = 200[/b]

Speed = 150[/b]

Renee