Help... First Layer is giving me inconsistent gaps

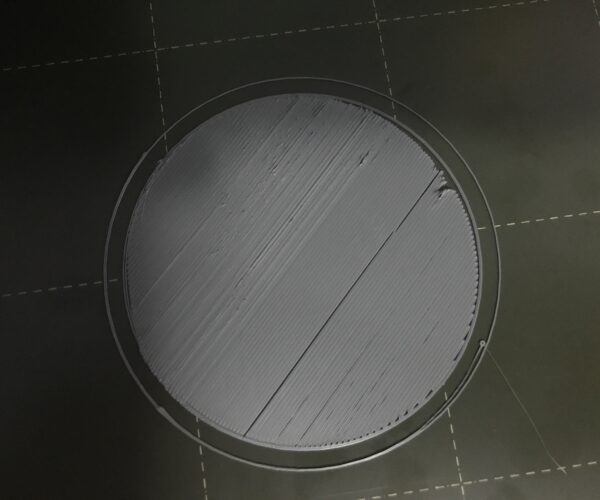

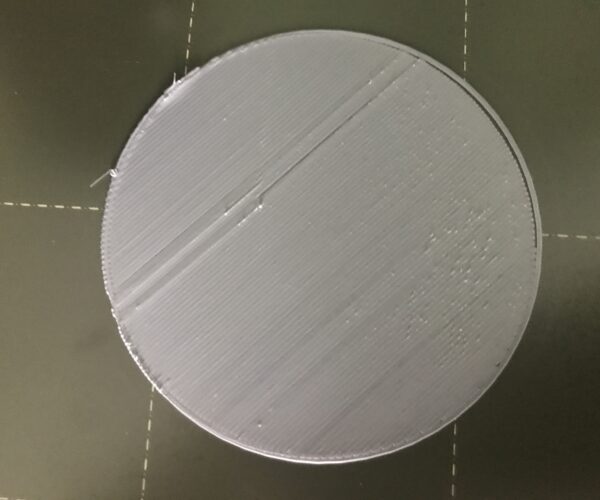

Basically what's going on is the first layer infill will overlap with the first layer perimeter and leave gaps on the opposite side, but only sometimes. I've tried tightening my belts, live z adjusting, and cleaning my extruder. I'm quite stuck on this. Thing is, this problem only seems to happen on the first layer. Any kind of help is appreciated.

Best Answer by Steve:

Have you checked the set screws holding the drive pulleys on the x and y-axis steppers? Your problem appears very much like a positional issue. It is not uncommon for these pulleys to work loose if not properly tightened. You did not specify, so I am assuming you built from a kit. When tightening these screws it is critical to first align one with the flat on the motor shaft and tighten it firmly and only then tighten the second screw.

If the screws are tight then look to other mechanical parts. Are the u-bolts on the y-axis bearings snug (be careful not to overtighten these as you will crush the bearings and damage them!). Are the belts properly tensioned? Is the x-axis carriage firmly affixed to the bearings?

Regards,

Steve

RE: Help... First Layer is giving me inconsistent gaps

EDIT: So, I fixed it, sort of. After finding out that the PINDA sensor wasn't tightened, I fixed that and it ran a lot better. But it still starts leaving overhang about halfway through the print and just not connecting the infill to the perimeter about a quarter of the way through the print. Any suggestions? Anything is helpful.

RE: Help... First Layer is giving me inconsistent gaps

Have you checked the set screws holding the drive pulleys on the x and y-axis steppers? Your problem appears very much like a positional issue. It is not uncommon for these pulleys to work loose if not properly tightened. You did not specify, so I am assuming you built from a kit. When tightening these screws it is critical to first align one with the flat on the motor shaft and tighten it firmly and only then tighten the second screw.

If the screws are tight then look to other mechanical parts. Are the u-bolts on the y-axis bearings snug (be careful not to overtighten these as you will crush the bearings and damage them!). Are the belts properly tensioned? Is the x-axis carriage firmly affixed to the bearings?

Regards,

Steve

RE: Help... First Layer is giving me inconsistent gaps

Have you checked the set screws holding the drive pulleys on the x and y-axis steppers? Your problem appears very much like a positional issue. It is not uncommon for these pulleys to work loose if not properly tightened. You did not specify, so I am assuming you built from a kit. When tightening these screws it is critical to first align one with the flat on the motor shaft and tighten it firmly and only then tighten the second screw.

If the screws are tight then look to other mechanical parts. Are the u-bolts on the y-axis bearings snug (be careful not to overtighten these as you will crush the bearings and damage them!). Are the belts properly tensioned? Is the x-axis carriage firmly affixed to the bearings?

Regards,

Steve

Aha! That did it. The pulleys weren't tight enough. Thank you so much.

RE: Help... First Layer is giving me inconsistent gaps

Glad to help. Happy printing!

Steve