Help analyze first layer issues

Hello everyone,,

I have a mk3 printer that has been used quite a lot in the last year (probably 10 kg of material).

Recently there are issues with the print not sticking to the bed.

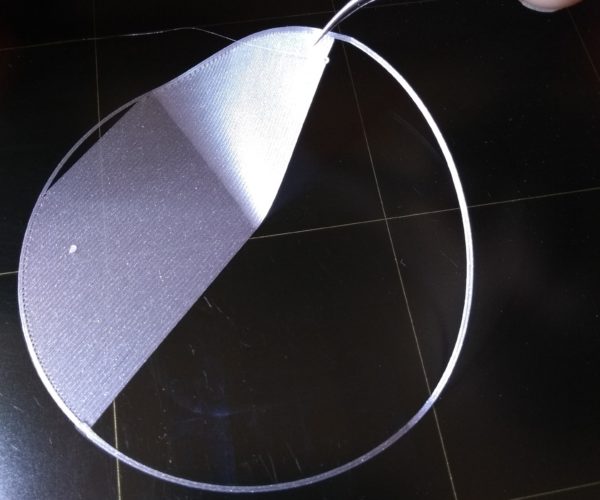

I cleaned everything as good as I can, and then tried the first layer calibration. I just can't seem to get the layer to stick unless it's really low (so the first layer is over extruded). Here's an example of the end of the first layer calibration:

(Please ignore the surface - it's just the table the piece was on as I took the picture)

The issues I'm seeing:

- It seems the first layer is too low - there's over extrusion on that first layer.

- It seems the first layer is too high - the edges of the printed square are not aligned, it seems the edges don't stick and lift up a bit.

- There are "tractor marks" on the extruded filament - this is new. I don't remember this from the past (or from other Mk3 printers). Maybe the extruder idler is too tight?

Any thoughts on what's causing this?

https://reverseimagesearch.onl https://emailchecker.vip/https://portchecker.pro/

RE: Help analyze first layer issues

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Help analyze first layer issues

Here's what I use to set layer one and Live-Z. The idea is to get the extrusion strands to weld together leaving no gaps. But not so low yoou begin building ridges at the weld.

As for adhesion, on new sheets in good condition, a hot wate wash and rinse usually does the job or restoring bed adhesion. On older sheets that have been used quite a bit, a scrub with acetone then washed and dried at a sink is sometimes needed.

The acetone removes PEI oxides that build up over time. The wash removes the residue from scrubbing the surface (a while film usually appears and needs to be washed off).

Wash with only paper towels; do not use any other kitchen cloth or sponge or dish towel. Fresh, plain paper towels are best. Avoid dish soaps with hand sanitizers, anti-bacterials, and scents. In all case rinse for a few minutes at 3 gpm (typical sink faucet) and use water as hot as you can get, rinse until the water beads and sheets off. Usually, a clean sheet will only have a few drops of water to dry off.