Help

Hello all.

Im sorry if this is a big cliche, but im very suddenly having huge problems with layer 1 adhesion.

It all started with a crash during along print. everything upto this point had been printing perfectly.

I guess I messed up the calibration, and so ran all calibrations again. since then ive had the hot end clog twice.

taken hot end out to unclog and changed nozzel

I bought a new textured print bed. cleaned old and new with IPA

I have tried new filament.

ive tried glue

ive been running 1st layer at super slow speeds

ive been running the 1st layer calibration literally hundreds of times. and reading multiple websites and youtube vids

right now nothing will print.

im so frustrated with this right now. any help

RE: Help

One of two problems is happening - under extrusion or your need to readjust your live Z with a first layer calibration. Start by redoing your first later calibration.

--------------------

Chuck H

3D Printer Review Blog

RE: Help

Hi. thanks all.

so I had another hotend clog.

cleared this.

ive also tried soap washing the print bed.

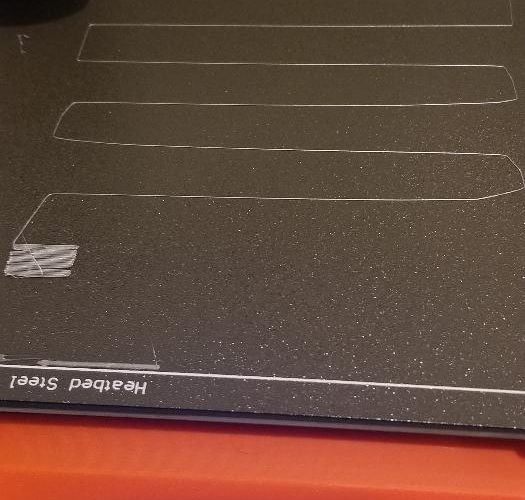

here aresome photos including 1 of most recent 1st layer calibration.

it extrudes well at the clearing streak at the start- and incidentaly this sticks well to the bed. and also at the very start of the long track part og the test

the rest however, seems to extrude little material,and gets picked up and smooshed around by the nozzle.

I have a feeling it is under extruding,

how to troubleshoot / fix this

RE: Help

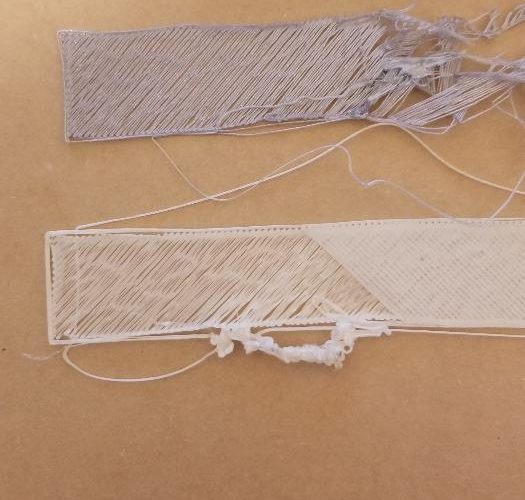

another 1st layer calibration picture

the nozzle seems to dragonthe filament layed down, and round the corners

also the edges of the solid partat the end curl up, seem to get stuck to the nozzle and lift up as it changes direction.

I have tried cleaning the outside of the nozzle (but only witha cloth and the nozzle at285 ( I dint have a brass brush)

Although I did replace the nozzle 0 successful prints ago), and the inside with the accupuncture needle.

RE: Help

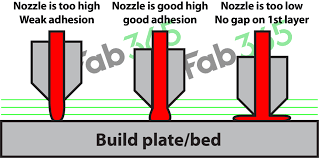

looks to me like the extruder is still too high...

have you enabled 7x7 mesh bed levelling via the LCD Menu?

have a look at this thread

there is a zip file in the first post, which contains three files, one for each of PLA, PETG and ABS

they give you a 75mm square, which is much easier to tune in...

if the strands look like individual strings, Live Z is too hign,

if the strands look smooth and joined together you are about right,

if the strands rook rough and start to buckle up, your live Z is too low...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Help

@joantabb

What do you mean by: start to Buckle?

--------------------

Chuck H

3D Printer Review Blog

RE: Help

@joantabb

What do you mean by: start to Buckle?

I use a 75mm x 75mm x .2mm square to check my first layer height. When the nozzle is too low you will see waves, ridges, or “buckling” start to show up in the layer.

RE: Help

@joantabb

What do you mean by: start to Buckle?

I use a 75mm x 75mm x .2mm square to check my first layer height. When the nozzle is too low you will see waves, ridges, or “buckling” start to show up in the layer.

Thanks. I have never seen it referred to buckling but now I understand.

--------------------

Chuck H

3D Printer Review Blog

RE: Help

when live Z is too low, you try to push too much plastic into too thin a gap, this causes the plastic to try and escape sideways under the nozzle,

this can lead to the new extruded plastic displacing the previously extruded plastic causing the previously extruded plastic to lift off the build plate

when this happens the print starts to get ripples like the sand on a beach as the tide goes out, where the printed filament has lifted (or buckled)

the diagram above may help demonstrate what is happenning...

I don't have a good picture of the results of live Z too low, have a look at the pictures in the 'life adjust Z my way' thread

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Help

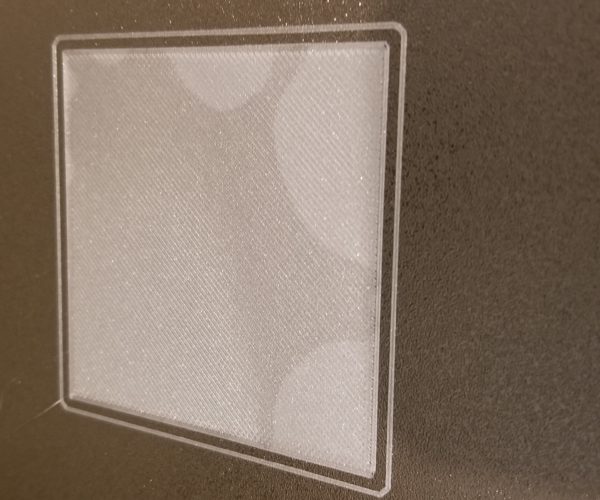

Hello. so Im printing out 75x75mm squares and seem to be having some improvements with lower nozzel positions.

Ill post some pictures when I have a few

one question. I notice the temps on this G code are for 225.

would it help me to up my temp to 225 for layer 1?

RE: Help

but seems not to be uniform, one corner or half the filaments are not fusing together

RE: Help

The delamination is due to poor bed adhesion (those light areas in the photo). You may want to try washing the plate in very hot water using a few drops of ordinary dish detergent (Dawn/Fairy depending on locale). Only use paper towels for scrubbing and drying, and keep hands and fingers away from the print surface at all times.

Once washed and rinsed (water must bead and sheet off the surface, otherwise it isn't clean), dry with paper towels, again, keep fingers at the edges only. Then place on heat bed and dry at 80c for about 30 minutes to prevent rusting.

ps: The stringy threads is due to the Live-Z level being too high. You need to lower (more negative) Live-Z until you are printing a solid sheet of plastic.

RE: Help

Concur with above, wash the bed again. Adjust your live Z. I just bought cotton gloves to protect the bed from my nasty hands.

--------------------

Chuck H

3D Printer Review Blog

RE: Help

THANKYOU!!

thankyou so much you guys.

I was really getting frustrated with this, but thanks to you we seem to be printing again.

I got the live Z dialed in. originally I was miles off.

and I printed this layer 1 at 30mm/s

I had gone down as low as 2mm /s before I think this was causing my extruder jams.. so all is well

layer 1 printing and sticking. and all at a reasonable speed.

Thank you , thank you thank you

Peter

RE: Help

THANKYOU!!

thankyou so much you guys.

I was really getting frustrated with this, but thanks to you we seem to be printing again.

I got the live Z dialed in. originally I was miles off.

and I printed this layer 1 at 30mm/s

I had gone down as low as 2mm /s before I think this was causing my extruder jams.. so all is well

layer 1 printing and sticking. and all at a reasonable speed.

Thank you , thank you thank you

Peter

You are welcome. Thanks for the update.

--------------------

Chuck H

3D Printer Review Blog