Ghosting, VFA or something else?

Hey,

I'm trying to improve the print quality of my new MK3s, that I assembled last week. I'm using the 3dBenchy as benchmark, using Prusa Silver PLA.

In the first print I've noticed something like ghosting. Then I've printed a fleet on benchys, trying to:

1. improved the X and Y belt tensioning several times. I've started from 286/290 and ended up to 258/268

2. re-assembled the Y carriage to check the bearrings alignment

3. moved the printer to the floor

4. sliced the stl instead of using the one in the SD card

5. moved the benchy to the corner

6. rotated the benchy orthogonal to the axes

The strange thing is that, after each test, I'm getting "exaclty" the same result, and the ghosting pattern looks the same !

The only different result I've got is using the standard 0.15 Quality profile, but with the "external perimeters speed" to 10 mm/s instead of 25 mm/s. This is clearly improving the quality.

Can you help me? What's the "out of the box" quality of the Benchy printed on your Prusa?

Thank you!

Riccardo

RE: Ghosting, VFA or something else?

There are signs of both: Ghosting and VFA

RE: Ghosting, VFA or something else?

There are signs of both: Ghosting and VFA

What do you suggest to try to diagnose/solve the problems?

RE: Ghosting, VFA or something else?

Firstly, compared to some, your first prints are really good.

Next, read this thread and see what you think then prepare to go off down the rabbit hole 😉

BTW, did you lubricate your bearings?, if not, then do it NOW!.

I'm an advocate of light machine oil regularly, but a semi fluid lithium grease would be better as it tends to stay in the bearings longer so no need for as frequent lubrication as with oil. Also, do not fully pack the bearings with grease, and do not use grease with PTFE in it, although it will all still be better than nothing at all.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Ghosting, VFA or something else?

Firstly, compared to some, your first prints are really good.

Well, I guess I'm probably not aware of which is the standard quality I should expect from the MK3S.

Next, read this thread and see what you think then prepare to go off down the rabbit hole 😉

Wow, a 46 pages deep rabbit hole 🤣. I've something to do the next few days!

BTW, did you lubricate your bearings?, if not, then do it NOW!.

I'm an advocate of light machine oil regularly, but a semi fluid lithium grease would be better as it tends to stay in the bearings longer so no need for as frequent lubrication as with oil. Also, do not fully pack the bearings with grease, and do not use grease with PTFE in it, although it will all still be better than nothing at all.

Sorry, I didn't mention that I've lubricated x and Y rods, with the lubricant that Prusa is sending with the kit (it should be lithium grease).

BTW, I've also printed and installed the Y-bearing to replace the U-bolt, but I've got the same result

RE: Ghosting, VFA or something else?

BTW, did you lubricate your bearings?, if not, then do it NOW!.

I'm an advocate of light machine oil regularly, but a semi fluid lithium grease would be better as it tends to stay in the bearings longer so no need for as frequent lubrication as with oil. Also, do not fully pack the bearings with grease, and do not use grease with PTFE in it, although it will all still be better than nothing at all.

Sorry, I didn't mention that I've lubricated x and Y rods, with the lubricant that Prusa is sending with the kit (it should be lithium grease).

I'm sure he refers to the ball guides in the bearings. See here.

RE: Ghosting, VFA or something else?

I'm trying to investigate why, if I set an "external perimeter speed" equal to 15 mm/s or less, ghosting is disappearing.

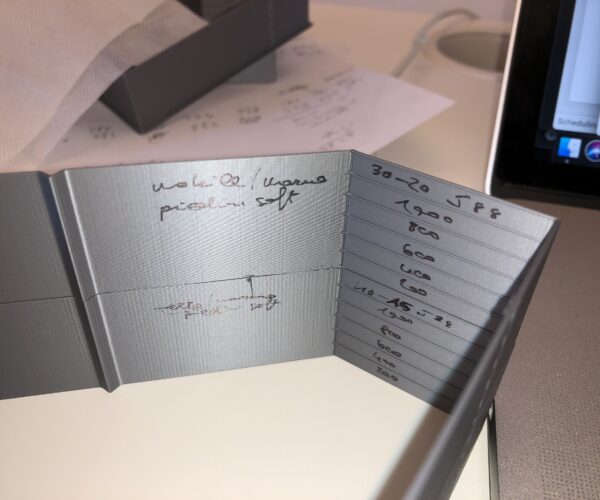

I've printed a calibration cube of 50mm, rotated 60 deg, to get some evidence of which axis is contributing to the ghosting. External perimeter speed set to 45 mm

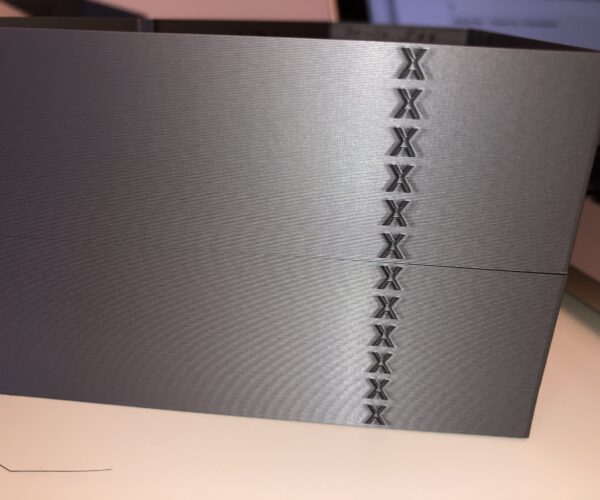

This is the front side: you can see more ghosting on the left side and after the letter. My interpretation is the x axis is the main contributor, because the vector is 60 deg. It looks like that is the acceleration that is creating the ghosting.

This is the right side. Less ghosting. Does this confirm that the problem is the accelleartion of the x axis?

Back view: ghosting in the acceleration phase of the X axis?

Left view: Ghosting after the letter. Always the acceleration?

What do you think about this?

Best

R

RE: Ghosting, VFA or something else?

Here is a bit of a debate going on about the merits of different lubricants. Tim is knowledgeable and his choice of lubrication is good, but could be better 😉 (But that's just my opinion - sorry @Tim):

But whatever you choose, like Tim stated, even car engine oil is better than nothing at all, the grease PRUSA supply is good, but you could definitely do with more to initially grease the bearings, this would then be followed up by occasionally lightly greasing the rods, no more than a thin film.

Also for info, after a few months, check your extruder cooler where the cooling fan is for gossamer filaments buildup which can eventually melt and drip onto your heater block as I found out. I'm going to get a can of compressed air or some sort of blower, and with a finger on the fan to stop it spinning, blow air back through the cooler to give it a clean out every so often.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Ghosting, VFA or something else?

Do you still have your filament on top of your printer?, try a reverse Bowden setup, initially, just feed the filament by hand from above the printer without the reel on top and see if this helps, the idea is to reduce shaking of the printer, also those soft feet PRUSA supply are not the best for reducing wobbling, ideally you want to print some rigid feet and put felt pads like the ones for furniture on the bottom, then place your printer on a heavy solid base like a slab or granite chopping board. You actually want to add fixed mass to the printer to stop it moving about.

Iv'e actually considered bolting heavy weights to the side of my printer, but ultimately it depends on what you are trying to print, if perfect test pieces is your goal, then you will be chasing the never ending nirvana for a long time, there comes a time, when you have improved your prints to a level that is acceptable and cost is not exorbitant.

For me this was reverse Bowden feed, granite chopping board, solid feet with felt pads, skelestruder, better pulleys and probably the biggest improvement for me anyway, 0.9 deg OMC stepperonline X + Y motors.

I am going to try some misumi bearings and rods, and use semi fluid grease instead of oil for lubrication, not because I think it is better for wear, but because it is more viscous which should help dampen down ringing a bit, but this will only likely be visible after all the improvements I have already made, my main artifact now is the pulley teeth, and some ringing but that's it, no more improvements after this.

If you do go this far, put the slab on some sorbothane hemispheres to isolate any vibration from whatever you are using as your work table on which the printer stands, this wont help with the ringing, but will silence the vibration transferred into the table right down.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Ghosting, VFA or something else?

And have a read of this and maybe play with your jerk values. Prusa seem to vary these between firmwares.

If you have carried out modifications, it cant hurt to try values around the PRUSA settings to see if your particular setup benefits from a slight tweak.

http://www.desiquintans.com/ringing

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Ghosting, VFA or something else?

I'm trying to investigate why, if I set an "external perimeter speed" equal to 15 mm/s or less, ghosting is disappearing.

I'm going to focus on slicer settings as I don't see anything in your pics that looks unusual.

Slowing down perimeter speeds does several things:

- It reduces the effect of acceleration and jerk between turning a corner and moving the nozzle up to full speed. Acceleration and jerk are well-known contributors to ghosting. This is more of a happy side effect. Prusa has made significant changes to the Mk3 acceleration and jerk settings since original release.

- It reduces bed sway on direction changes. Compare faces on the X & Y walls to see if movement of the heavy bed impacts the severity of ghosting.

- It gives the filament more time to heat and extrude evenly. This is more of an issue with adhesion.

You can try the extruder linearity correction calibration procedure to see it if helps with the moire patterning. I found it beneficial. It's always hard to tell from pics if this is a problem or just a lighting issue.

Did you notice any change moving the printer onto the floor? A vibrating surface can contribute to issues. I wound up mounting my Mk3 on a concrete paver when I moved it to a cabinet.

Edit: How big is that XY cube? It looks large in the pics.

RE: Ghosting, VFA or something else?

@chocki @lichtjaeger: I've read the article you've suggested https://prusacommunity.com/set-your-bearing-straight/ . It says that "One of the many misconceptions about bearings is they need to have zero friction. This is why people like Igus bearings. The problem is when you have no friction you also don’t have smooth acceleration or deceleration. Basically the less friction the greater the backlash. So yes, Igus bearings hurt your print quality. I said it and I’ll say it every time. If you like sloppy bearings and lots of additional ringing in your prints or lots of overshoot then feel free ..."

So I'm not understanding if I should look for better greasing or better friction 🤔

@chocki @bobstro: I've already tried to move the printer to the floor, to use felts, to feed the filament by hand from above the printer without the reel on top. Without success 🙁

@bobstro: I've did the extruder linearity and it looks like I'm not needing correction so far. Regarding the cube. It's 5cm x 5cm x5cm. I wanted to have a longer side to diagnose problems

@chocki: I'm going to try this: http://www.desiquintans.com/ringing .

Guys, thank you so much for your help!

This is an awesome community!

RE: Ghosting, VFA or something else?

Quick update.

I've replaced the X bearings and the Y bearings with new fully lubricated bearings. I've done the full calibration.

I've reprinted the benchy. Same ghosting, same pattern, same result 🙁

I'm running out of options and ideas.

RE: Ghosting, VFA or something else?

That appears to be extruder (non-)linearity. If the E-linearity calibration Bobstro mentioned does not affect it significantly, then really the only way to get rid of it is to change to a different extruder or extruder motor (0.9 degree steps). Personally I run a skelestruder with 3.5:1 gearing which eliminates that artifact nicely.

But beware, surface finish is a rabbit hole. The next thing that will show up is VFAs, which are reduced by changing the X/Y motors for 0.9 degree steppers, at that point ringing becomes the most prominent visual artifact.

RE: Ghosting, VFA or something else?

Same as Vintagepc, I to have a skelestruder with 3.5:1 gearing fitted with 1.8 Deg motor and both X + Y have 0.9 Deg motors and even with all this I can never get a truly smooth surface and yes, ringing is the most prominent visual artifact.

I am in the process of re-printing my printer parts more accurately now that I have some experience under my belt, to see if it improves anything, but mainly so that I have a spare set in case something breaks, and am going to use grease in the bearings instead of oiling as it is more viscous than oil and may help reduce ringing.

Here is my result before modifications and after modifications of going from standard 1.8 Deg motors on X and Y to 0.9 Deg motors and modified firmware.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Ghosting, VFA or something else?

Another quick update.

I've done several other tests. I've tried different types of feet, rigid, absorbing, and the factory ones. I've moved the printer to a marble base 45x45x6 cm. Weight 30 kg!

Long story short: the quality cannot be improved. The only way to improve the print is to lower the speed. It looks like that 15-20 mm/s for external perimeters is the best parameter you can use.

I think the real problem is the x-axis and x-carriage stability. The two rods are not so stable (eg. you can easily move the x-carriage 1-2 mms on the Y-axis). That's the reason why I'm getting ghosting especially in the movements that are simultaneously involving X and Y movements.

Example of a 45 deg perimeters. Up: 30 mm/s with different acceleration(200 to 1000mm/s2), Bottom 40 mm/s.

Example of only x movement perimeter

Best

R

RE: Ghosting, VFA or something else?

After having been printing happily with Ultimakers for years I finally decided to give a simpler printer a go as I was hearing good things about Prusa.

Now I don't know what a Prusa should print like. Maybe this is as good as it can do, but I was hoping for more.

I've just assembled my printer yesterday and am seeing the exact same thing.

So far I've tried to:

- Take a bit of tension of the belts

- Print a e linearity tower, but for me the best results are with it set to 0