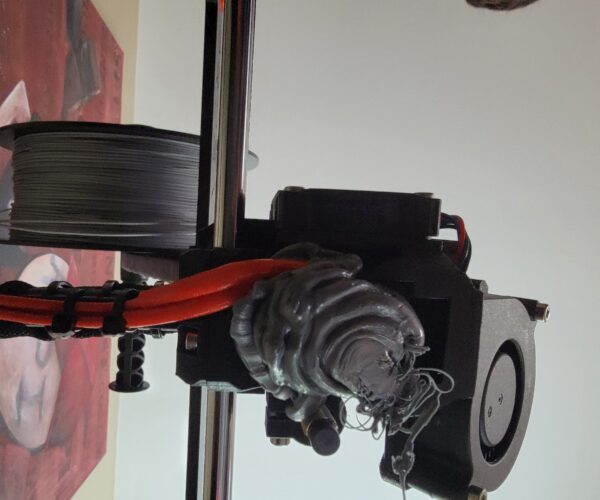

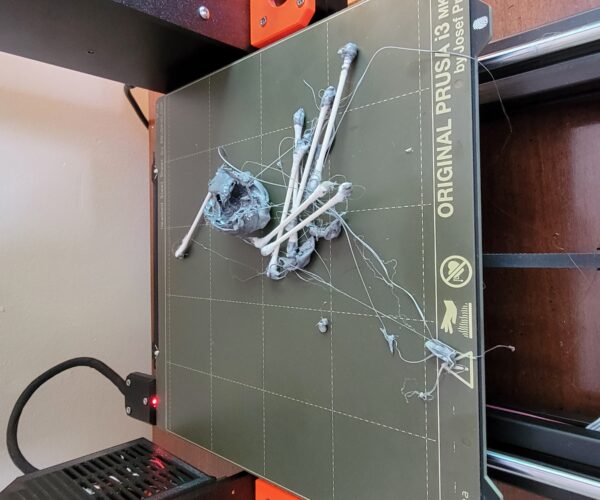

Full plastic block

I just got my new printer set up yesterday. The first two prints went great and I was very impressed by the quality. The 3rd one did not go so well. I'm guessing it was due to some settings I messed up in the slicer. I know am going to have to basically chisel this thing free, but does anyone have any tips for this sort of situation? Anything I need to be particularly careful of or avoid?

RE: Full plastic block

Failed adhesion can cause this.

--------------------

Chuck H

3D Printer Review Blog

RE: Full plastic block

Sorry for your loss... but those can generally be cleaned up with time, effort, and great care to not damage the wires when peeling and chipping the glob off. Buy a spare hotend from Prusa, you'll thank yourself tomorrow.

As for why it happened?

- Getting Layer One properly calibrated is something most of us have all learned to do well.

- Keeping the print sheet in a pristine clean condition is something most of us have all learned is mandatory.

- Touching the print sheet with your bare hands is something most of us have all learned to avoid.

- Screwing with slicer defaults as a new user is something most of us have all learned to avoid.

- Not reading the material shipped with the printer is something most of us have all seen cause problems.

- And - watch the print to ensure layer one is printing as expected before walking off...

ps: there are several threads with the subject of removing globs; do a search of the forum; it will take time with how results are presented, but the info is there. Short form: remove the hot end, power it up off the printer to warm the plastic so it peels off rather than chipping, don't pull the wires, ... etc.

RE: Full plastic block

Do not chisel! Best tip I was ever given for dealing with the Blob of Doom was "heat got you into this mess, heat will get you out of it". Heat the nozzle up, using a hot air gun if necessary, and slowly pull at it. With any luck, most of it will come off in one chunk.

- Be as careful as you can around the wires.

- Be prepared to replace the thermistor and heater cartridge if the wires are damaged.

- Be prepared to replace the heater block if you are unable to remove damaged thermistor or heater cartridge.

- Be prepared to replace the heatbreak if you are unable to remove it from the heater block (or snap it in the process).

It's also common to need to print or source a replacement part cooling fan duct and PINDA mount.

I like to use strips of corrugated cardboard to "squeegee" soft filament away, particularly if the printer itself is heated. Wooden toothpicks are handy for cleaning up gunk around the wires. Go slow. Never leave the printer unattended until at least the first layer has successfully printed. If the first layer doesn't look solid, the rest of the print won't be solid.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Full plastic block

Concur with all of the advice above. You walked away, with a bad layer 1, print lifted, hot nozzle rammed into it and melted on - carried it merrily around the bed in mid air all the while happily adding more filament to the pile.

Assume it's PLA since it is one of your first prints. Use the pre-heat feature - but heat for next level filament up (PLA blob, use PETG preheat, PETG Blob, use ASA preheat, etc. ASA/ABS blob - well you are screwed more, but heat and patiencce.

Bring your Z up to about 150, 175 so you can get at things. Don't take it apart. Don't pry on it at all. It'll fall off and start dripping off. Use picks, sticks, needle nose, to get all of that out of the fan shroud, out of the fins on the extruder body (shiny metal thing), but be Very Very careful around the wires on the heat block - you don't want to break them or stress them.

RE: Full plastic block

I bought a fully assembled hot end from prusa, I think it was 100 with shipping several months ago now. Best to have a spare on hand for cases like this. You should always watch the first several layers go down before you consider walking away. I've had similar, but not that bad and definitely learned my lesson lol

RE: Full plastic block

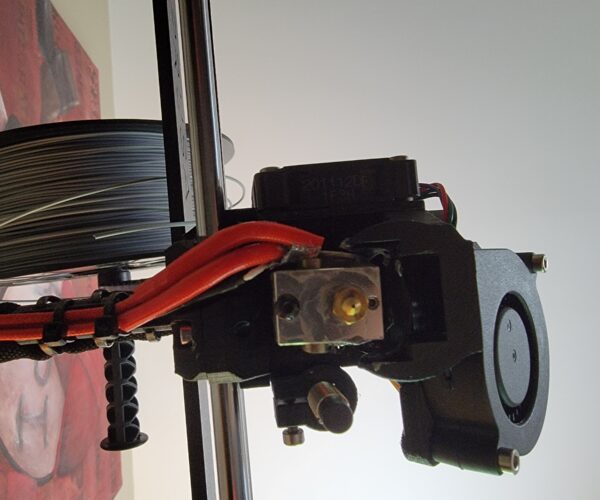

Thank you all for the tips. Heating it up to PETG temps really did the trick. Once it got up to temp, I gave it a minute or so and was then able to start pulling bits away. Like you said, it came away mostly in one big piece. Then I carefully pulled away the smaller chunks that didn't come with the main chunk, and then I swabbed it a bit to get the fully melted bits. It's not 100% clean, but it looks like it should do the trick. I am recalibrating now and will do a test print afterward. Not to worry, I won't walk away this time. Also, I wiped down the bed with some isopropyl alcohol and will avoid smudging the surface. I will get replacement parts when/if I can, but I will certainly print out what replacements I can ASAP. Thanks again for the help!

RE: Full plastic block

Glad you were able to salvage! Having a spare assembled hot end on the shelf just in case isn't a bad thing though. When I upgraded that printer to have the MMU2S on it, I ended up replacing the hot end at the same time with the spare.

RE: Full plastic block

@brachtj

That is good news. It is not the worse I have seen, but not what you want to greet you.

--------------------

Chuck H

3D Printer Review Blog

RE: Full plastic block

T Also, I wiped down the bed with some isopropyl alcohol and will avoid smudging the surface. I

A complete waste of time and effort and you will be doing this exercise over again. And I am not saying this lightly.

Learn to wash the print sheet at the sink using a drop of dish soap/detergent and very hot water. It actually removes fingerprints and oils that people naturally leave when touching the print sheet. Oils account for 90% of adhesion problems. Bad layer one cal is important, too; but fingerprints are worse. Use only new/fresh paper towels as your scrubber and to dry the sheet. And handle the sheet only by the edges.

Alcohol is sometimes needed to clean off certain plastic residue - but a soap and water wash afterwards is always needed.