Flow and/or bed adhesion problems

Hey all,

I've recently upgraded my Prusa MK3 kit to MK3s

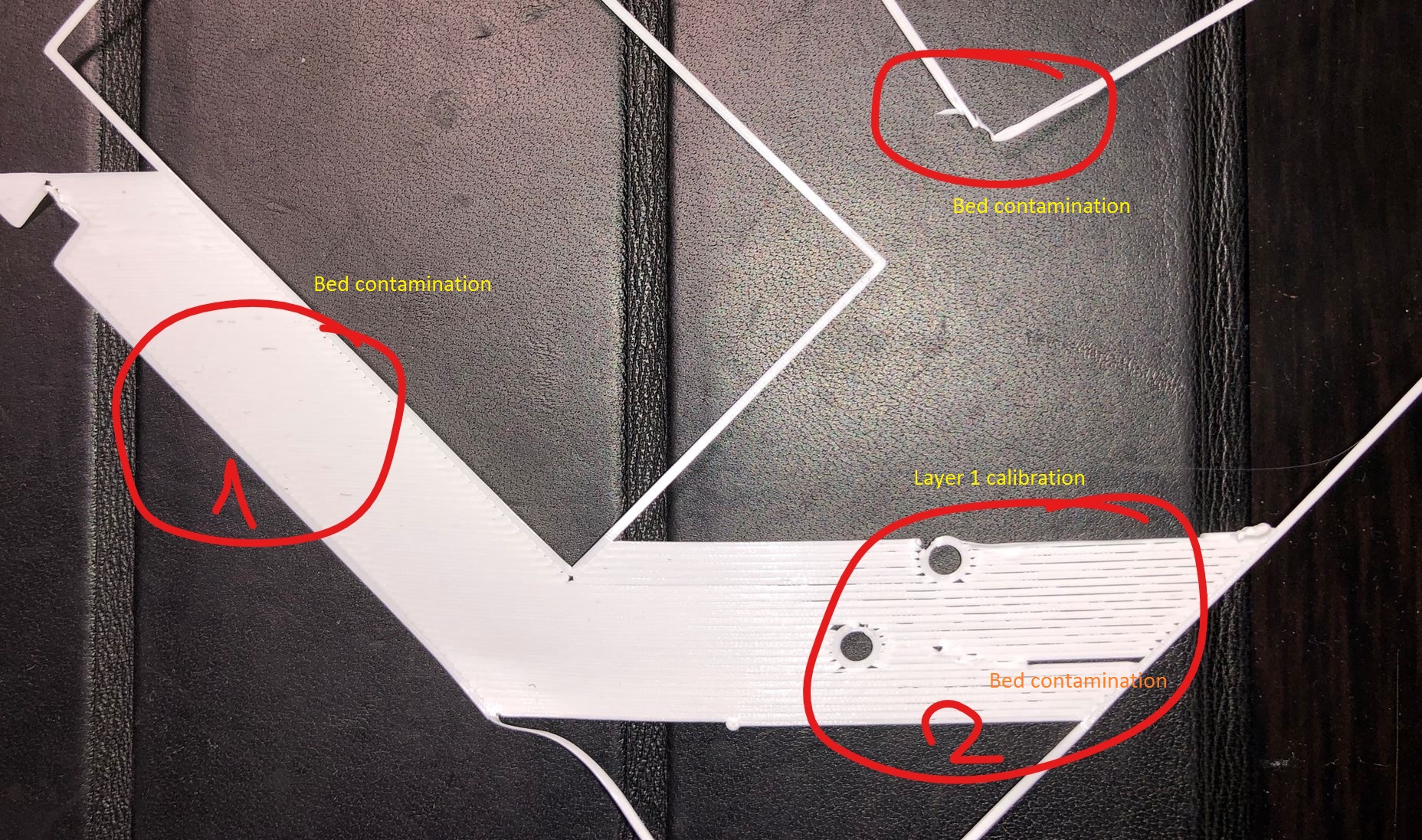

I have big problems with bed adhesion and/or flow, see the photos:

https://imgur.com/a/GNmhpTG

What happens: filament will unstick from the bed (Or judging by the filament width, it's not extruded enough so it would actually reach the bed?).

When printing first layer, sides will either curl up or be removed altogether; resulting in Big Blob of Death (As seen on the tissue) - it just catches all plastic, and blob it without any adhesion to bed. If they stick properly though, first layer seems okay.

IF first layer is printed correctly enough (E.g. benchy, or some of my own slices) it will print other layers very, very well.

What I've tried:

* Extruder

- Cleaned the nozzle

- Removed the nozzle, cleaned it, and re-seated it

- Under and over tightening of the tension screw (Last test was overtensioned I think, as seen on photos, but please note - pulley teeth barely bit the filament, so maybe here lies the problem?)

- Extruder rate adjusted to E281.2 from E280, i have now 100% extrusion match, it was tested on both configurations

* Filament

- ABS works better

- PET, as seen on the photos, barely works

* Bed

- Tried with and without glue, with glue the results are better, but still not consistent

- Removed, re-leveled, everything is okay according to tests

- I do not have termometer, but bed seems hot enough. Tried higher temp and lower temp

- Z calibration: With PLA first layer is generally okay, but during normal print speeds it will break off

I think that the problem lies with filament being not fed at the expected rate? But only at higher speeds, as the layers > first one are okay.

Any ideas?

Re: Flow and/or bed adhesion problems

If a gluestick helps PLA adhere, the bed it dirty and needs a thorough cleaning. I've seen this with some brands of PETG, too.

Hot Water wash: as needed

Handle the bed only by the edges.

Wash the bed in hot water, use a fresh paper towel as a wash cloth, with a few drops of plain dish soap (Dawn, unscented, no anti-bacterial, etc.). Rinse well in hot water - if you have very soft water, rinse a bit longer.

Dry the bed with a fresh paper towel.

Handle the bed only by the edges.

Place bed on printer.

Alcohol rinse: every few prints

Once in a while, an alcohol rinse is helpful.

Pour a 5 cm puddle of 91%+ alcohol in the middle of the bed, use a fresh paper towel to scrub the bed. Wipe up all the alcohol.

Streak test: when contamination is suspected and after a wash

With a fresh piece of paper towel, and very clean fingers, dampen the towel with 91%+ alcohol, and wipe the bed side to side moving back to front, like you're painting it with alcohol. The alcohol should be thin enough on the towel it quickly evaporates. If you see any streaks, the bed is dirty and needs a wash.

Acetone wash: infrequent

Pour a 2 cm puddle of acetone on the bed, scrub it around with a fresh paper towel. It will evaporate fast as you clean. This step removes PEI oxides that form over time and with heat, and improves PLA adhesion to a like new state.

Re: Flow and/or bed adhesion problems

Exact same issues after upgrade

Re: Flow and/or bed adhesion problems

Same problem here (update from MK3 to MK3s). Neither the cleaning nor various other solution attempts have helped. 😳

This is what a printout looks like:

Especially the starts don't stick properly.

The quality of the print varies greatly. The first part is ok and then it gets bad.

I use 1.75mm PLA from Prusa

I have no idea. I didn't have the problems with MK3.

Suggestions?

Re: Flow and/or bed adhesion problems

If you are able to get some good prints, that means it's not a PINDA level or other mechanical issue. Tim's advice is solid. For anybody new to a Prusa, don't fight this or try to think of reasons it won't work. Just try it. You'll find dozens of posts (like this one) on these forums that start out with exactly these sorts of problems and end with "well, I finally tried the sink and it worked." Do these things in this order:

There's a bit of a trick to adhesion, getting the bed clean and mastering Live-Z. Once you get the hang of it, you'll get good results. Good luck!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Flow and/or bed adhesion problems

Okay, so for me it's mostly solved. Issue did not stem from the bed, as it was cleaned, re-cleaned, glued, cleaned, acetone, alcohol, soap yadda yadda.

What did help is actually screwing tension screw really tight (Which I'm worried will reduce the longevity of the parts).

My thought is - By default, new PTFE from the MK3S upgrade is actually just slightly 'inside' extruder gears, so I assume that I've just squished it with tension screw - because filament is still not damaged by teeth all that much

Edit: Also, I've fiddled hard with z-level, for PLA I've used -0.440, and for PETG the correct setting was -0.510

PLA is Prusa, PETG is prusament

In the first post I've mentioned ABS where i meant PLA.

Re: Flow and/or bed adhesion problems

If you have to jam the tension then something is seriously wrong with how you assembled the upgrade. You may want to go back and review what you did.

Re: Flow and/or bed adhesion problems

That's a possibility, but judging by another post ( https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/mk3s-stops-extruding-mid-print-filament-grinding--t28052.html ) this seems to be a common problem.

Probably will do the same, trim the PTFE that is

Re: Flow and/or bed adhesion problems

That's a possibility, but judging by another post ( https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/mk3s-stops-extruding-mid-print-filament-grinding--t28052.html ) this seems to be a common problem.

Probably will do the same, trim the PTFE that is

You could always try the second piece of PTFE supplied with the upgrade kit in case one of them was mistakenly from the original MK3 batch?

Re: Flow and/or bed adhesion problems

Second one has the same length as the first one; both shorter than the stock MK3

I'll disassemble it today and check the length if it matches expected length, if not - I'll shorten it. I'm only worried about bevelling on the input side of PTFE. ;/