first print feedback

I feel like the first layer is printing pretty well now, but I'm new with this, so my opinion isn't worth much. I'd appreciate a bit of feedback.

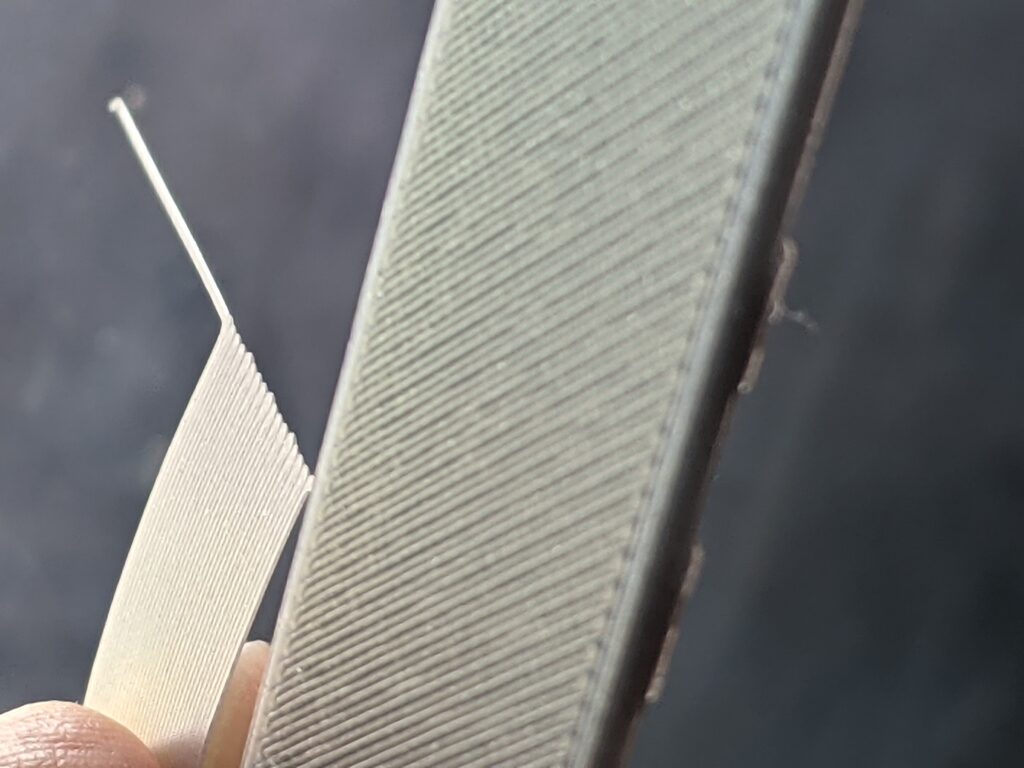

On the live-Z setup print, the little square was very "stuck" to the bed and the sheet side is very smooth. To my finger it feels perfectly smooth and glossy, the top side has the slightest bit of texture that my finger can feel.

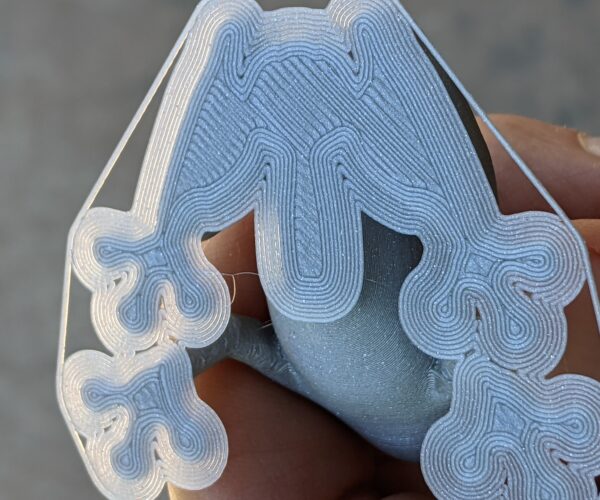

The Prusa logo test print also had great adhesion and has a pretty smooth bottom surface but my finger feels the slightest bit of texture, not as "perfect" as the single layer test. The larger outline came out great, but I snapped a picture during the first layer wondering if the slight rounding isn't correct.

To me, it's like the Z height is correct on the setup but too high on the Prusa logo. Thoughts?

print bed side of single layer test and Prusa test logo

print bed side of single layer test and Prusa test logo first layer of Prusa logo test print

first layer of Prusa logo test print

RE: first print feedback

The only complaint/question I have on the logo test print is the top layer. It feels rough, scratchy like sandpaper, but the "top" of the base (not the raised letters feels pretty smooth, almost like the bottom, bed layer. Maybe this design is supposed to have a textured top? Could something have happened mid-print?

RE: first print feedback

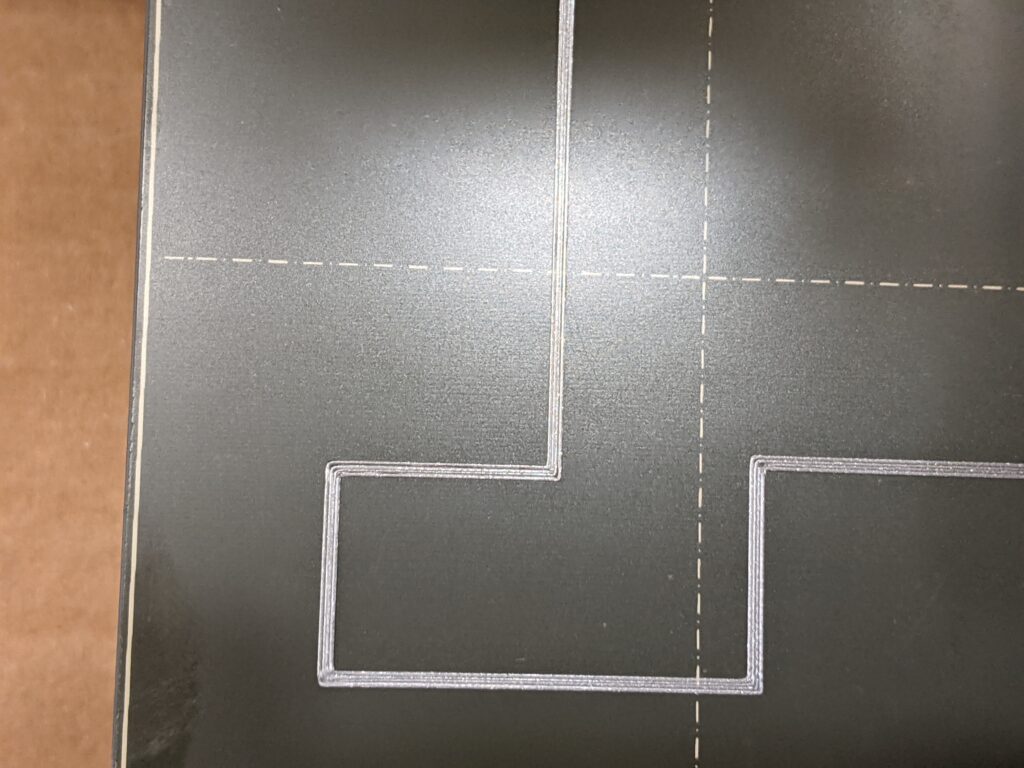

Your first layer is still not close enough. The pictures you show indicate that the threads are not getting squished together. There should be NO lines in the result. Your frog probably would have failed to print if it were not for the brim (no brim should be needed for that print). Keep going lower until the bottom layer is perfectly smooth and you don't see any separation between the lines.

RE: first print feedback

Your first layer could go a fraction lower, you are very close. Go down until the test square has a rough or wavy texture and then back off until it is just smooth to touch.

Bear in mind that the Prusa logo is a carefully designed, forgiving, object, designed to be an extremely easy first print. It's intended to work with a newly built, probably not well set up machine. It's the exact opposite of a benchy or a torture test.

Cheerio,

RE: first print feedback

Thanks for looking at these. The treefrog was printed at -1.30mm, which at the time was a bit of a blind guess. After that, but before seeing your feedback, I used feeler gauges to try to measure something quantitative. I figured out that 0.2mm height corresponded to about -1.29 for me (so the -1.30 guess was actually lucky). Then I did a bunch more single layer test squares. Here are the most useful data points

-1.30 treefrog

-1.29 (0.2mm measured height) the top surface has some minor rough/scratchy spots

-1.27 lowest offset that still has smooth top surface

So now, I think I'm at a point of compromise. I can't go to -1.30 or lower and maintain a smooth finish, but both of your expertise effective said that it needs to go lower, so I'm thinking your expertise over-rules my roughness feelers. I'll try some more tests lower and see where it starts to really fall apart (and maybe do the first layer of the frog to see how low I'd have to go to get those brim lines to be 100% gapless)