First Layer problems - Inconsistency

I've really struggled with my Prusa MK3S lately. It was printing fine a while, but I started having adhesion problems and I felt like a textured steel sheet would help me out (note I was having the same types of issues before replacing the sheet).

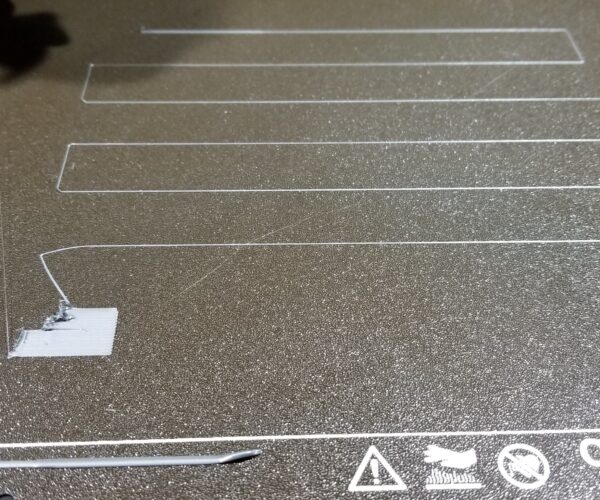

Here's the results of my first layer calibration from the prusa menus. When around the -0.675 range the long lines won't stick. At -0.700 the lines stick but I get it won't stick and get what I believe to be good results. I end up with the best looking results with a Z value of -0.700. This seems to adhere nicely, gives nice clean corners on the lines and gives a smooth appearance to the last square section.

What is this indicative of?

I think I may have totally messed up the tightness of this screw that control the gears that feed the filament. If you could point to or advise me on the steps to make sure this is correct that would be helpful too.

I've been at this all day and it's been getting worse and that's why I've stopped and come here.

A tremendous thank you for any suggestions!

Best Answer by rmm200:

Bit of bad news for you. The textured plate is far harder to get good adhesion.

Scrub your plate with hot water and unscented detergent. Dry with a clean paper towel - and never touch the print surface.

Use no IPA this time.

Now print a calibration square from this topic:

Adjust your Z while it is printing. Stop adjusting when the threads start to merge. Post your result here.

The built-in calibration square is pretty worthless.

RE: First Layer problems - Inconsistency

Bit of bad news for you. The textured plate is far harder to get good adhesion.

Scrub your plate with hot water and unscented detergent. Dry with a clean paper towel - and never touch the print surface.

Use no IPA this time.

Now print a calibration square from this topic:

Adjust your Z while it is printing. Stop adjusting when the threads start to merge. Post your result here.

The built-in calibration square is pretty worthless.

RE: First Layer problems - Inconsistency

@robert-rmm200

Thank you for your help.

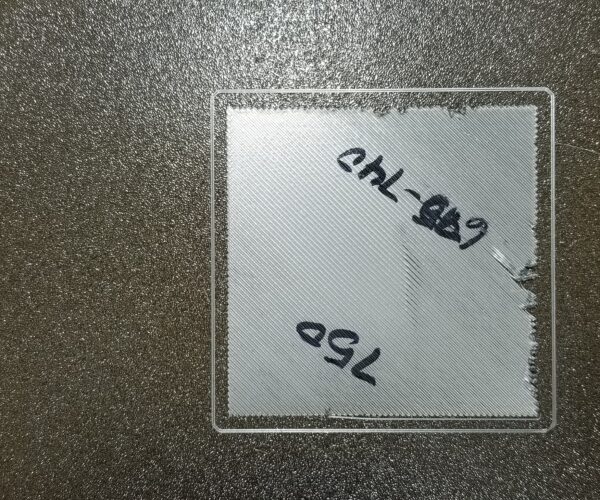

I hadn't cleaned my textured bed with hot water and soap before, I think that was a very helpful suggestion. Using the v6.1 of that calibration square got me the results I was looking for and here they are:

I'll run it one more time to see if I can narrow in on a value between -0.775 and -0.800.

The reason I got the textured bed was because I thought it would have better adhesion. Oh well, live and learn.

RE: First Layer problems - Inconsistency

You are making fantastic progress!

Textured bed is invaluable for PETG. That stuff adheres too well to the smooth plate.

Also, it is nice having a choice of bottom surface texture. I think the textured surface looks really nice...

RE: First Layer problems - Inconsistency

Hi there! i am having a similar problem. I was printing with various filaments, decided to upgrade to the MK3S, tried printing with Nylon and literally nothing would even extrude. I thought it was a blockage. The printer was inactive for a month or so. Since then, i tried printing with the prusa PLA, passed all calibration tests besides this first layer calibration. It seems to print ok to begin with but when it reaches the middle section of the snake, it thins out and struggles to extrude and then finds it position in the latter third. The very end bit is also the same, prints the first part, reaches the middle and nothing appears and then extrudes again. What you see is consistent every time, virtually identical. Any thoughts?

RE: First Layer problems - Inconsistency

Are you using a recent firmware? 3.8.1 is the latest!

are you using 7x7 mesh bed levelling?

select via LCD menu

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First Layer problems - Inconsistency

@joantabb

I followed the directions from your answer to my feed about adhesion. I live adjusted to 100 and the first line on the front left corner adhered good as well as lines closer to the edge but then more towards the center of the bed.

Then I started to print the batman logo and of the first layer started not adhering. Do I need to up the negative number on the z level and raise the temp on the bed because lines are still separated from one another. I am using default temp for PlA. I am thinking that I should adjust the live z some more before attempting to fool with temp.

Any suggestion would help. and thanks for the videos in my post. I know how to do the 7x7 leveling and adjust the live z now, but again I need to know what exactly I should focus on. More live z from -300 or bed temp for pla.

RE: First Layer problems - Inconsistency

@danny-l5

Danny I am so happy for you. Your calibration looks great. I am still trying to figure mine out. My bat logo looks like a disaster.

Your first calibration square was progress none the less. I am sorry but I had to laugh at teh rough edge of your square. It looks as if a rat decided to help himself to your square while you were away.

Again, good job!

RE: First Layer problems - Inconsistency

@joantabb

I already had the latest firmware version but reflashed it anyhow.

Changed to 7x7 mesh bed levelling but I still get the exact same problem.

What could it seem to suggest when the inconsistency of the line is virtually identical? It must be indicating something quite specific? If it was a blockage, surely it would be random each time?

RE: First Layer problems - Inconsistency

I am definitely a newbie. What you are saying makes sense, though. If it is a frozen piece of filament, dirt, or other obstruction, it should not make an identical pattern repeatedly, right? Other things might be that it starts and stops heating, changes the feed rate on the spool of filament at some time you did not request? Those are just what I can guess; wishing you good luck on curing it.

RE: First Layer problems - Inconsistency

@wdash

Yeah! If you have answers to those questions, they're more than welcome. It is almost like it is too perfect to be anything other than code related. Especially at the end how it lands exactly in the middle every time. Unfortunately, I cannot look in to this and test it as the machine is down until I receive a replacement part that I damaged. I will update my findings at a later date.

RE: First Layer problems - Inconsistency

@1256hubster

Well I used the 7x7 mesh leveling with the square test provided by Joantabb.

If you look at my bat it was horrific. What I did was go back and raise the PINDA up a bit so that it barely has any pressure against the zip tie (guidance from handbook) and then I did negative z adjustment (-550) and now I was getting tremendous results.

What part did you break? I cracked the housing for the x axis motor when i screwed in the tension screw to far. I thought I had not put enough tension on the belt, but apparently I did the first time so i unscrewed the tension screw and am fine now. Thank goodness it has not been an issue and I am now able to print.

What looks like to me from my experience of calibrating now is that your bed may not be leveled correctly, but if your running 7x7 bed leveling then your issue is out of my league.

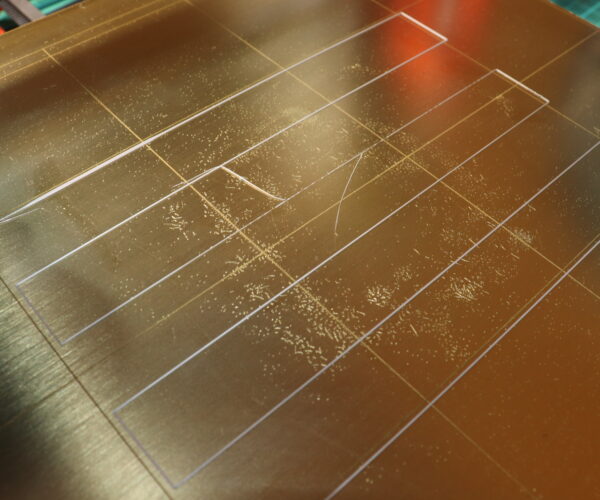

Here are some pics of what I have printed. These two parts were printed on transparent transition PLA from Filastruder and they turned out a nice translucent color. I was able to see through them. The parts were for our Epson wide format printer (7890) at work which we were not able to get parts for becuase there are not Epson part numbers for it (maybe Epson figured someone like me would come up with the idea to 3d print their own). The parts go to the catch tray, however; I had to improvise the bottom part. As you can see I had to redesign a part that wrapped around the railing becuase the original part attached to the railing from underneath with screws and mounted to the side of the railing. Since our printer is big and in use all the time I did not want to try and get another employee to try and hold it tilted up (and not risk it being dropped and we are out a wide format printer), so I could unscrew the broken piece as well as the intact piece on the other side to dimension the new piece. I decided to go with a less aggressive approach and make a simple snap on piece with a hole housing to pop the catch tray rod into along with a backing to keep the rod from moving back but static. I was thinking about moving the layer height down but after printing the top piece I liked the slight rough look and decided to not try and make a smooth piece. Tell me what you think?

RE: First Layer problems - Inconsistency

Hi everyone, I have had the printer for two years and have never been given a solution for a problem like 1256hubster. In my case I have in the front right corner that the layer is much more compressed than in the rest. I have tried putting springs on each of the bed clamping screws but the same thing always happens.