First layer print troubles

Hi there, I have recently assembled my printer and to my knowledge it was done correctly and I took extra care and time in doing so as this was my first time. After assembly I proceeded to follow the calibration guide and I achieved the best result possible for the axis calibration. I took a few turns at the first layer calibration and found that the best results for me were achieved at a z value of -0.850mm ish. I then proceeded to print a benchy. The benchy had no issues and I was really happy with the outcome and quality. However, after this I have been unable to get any first layer to go down properly. After I have removed the oozing filament from the preheat and proceed to start the levelling process of the print, there is sometimes still some filament which manages to seep through (the issue still occurs regardless of any oozing). When the print moves onto the intro line, some of the filament always strings upwards onto the extruded nozzle, this in turn means that when it moves to print the first layer outline, the filament always strings up onto the extruded meaning it’s impossible to even get a single layer down. I have spent hours testing different ideas to try and solve this, ive reduced the temperature from the standard 215 for pla down to 200 etc and also reduced the print speed but to no avail. I have attached a video which should show the problem I have described in a bit more detail ( excuse my recording skills haha). So any help or advice towards solving this would be much appreciated! Many thanks in advance!

RE: First layer print troubles

Hi,

Simple things first when trouble shooting.

So the first thing I would do is pull the metal print bed and wash it real good with hot water and a fragrance and hand conditioner free dish soap. I use paper towels to wash and dry my print beds when I clean them. Make sure to handle the bed by the edges as much as possible to prevent finger oils from contaminating the coating. In between washings I use either a plain window washer spray to clean between prints or some isopropyl alcohol. But hot water and dish soap is best.

After I'm sure of the cleanliness, I do a first layer calibration to get that first layer as good as I can. So run the Z-life square again. Look for pillowing. That means things ain't sticking to the bed well and your nozzle will need to come down again.

To eliminate the oozing, many people use a custom G-code intro. https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-general-discussion-announcements-and-releases/oozing-nozzle-while-doing-bed-leveling/ is a good discussion about making a custom startup G-code. This will help prevent those strings from welding to those parts we want to stick to the plate.

RE: First layer print troubles

Oozing is no problem, just before printer starts to move, remove filament, after that a little filament is no problem.

Most important for printing is:

1. clean bed, wash the bed with dish soap, a few times, a new bed will stick a little less.

2. First layer should be 100%.

Both settings are for good sticking to the bed, and to get a good model higher up in the model.

3. tip: Every print you start:

Check the first lines and adjust the z-layer,

then wen first layer is finished, check firts layer if is sticking enough or if it is already releasing.

All of this also prevents the big ball of filament that sticks to your nozzle , and what is almost not to clean.

How I work in general:

A new sheet will stick less then a used one.

PLA sticks more difficult on a powder coated sheet. Is still possible settings need to be more preciese.

This how I work on a pei sheet(there are always exceptions):

Most important to 3d printing is:

1. 3d print will never be like start and i have the print, there will always be problems!!!!!!

2. A clean sheet, use dish soap, then you can print on it. A few prints you can use alcohol, then again dish soap,

big flat models and models with small footprint on sheet- use glue stick(and not every glue stick is the same,

use one that makes a thin layer), and big flat models and small footprint, use a big brim attach to model so footprint is bigger.

Petg sticks to much on the pei sheet, use window cleaner, this leaves a layer on the bed, so it does not stick to much.

3. To get it stick very good, a 100% first layer is very important, see youtube for movie on this.

Every new print watch the first layer, and look if it is 100%, this will also prevent a big ball of filament on your nozzle wen model let loose during printing.

Extra: (normally not needed).

First layer, print hotter.

First layer slower.

Bed more heat.

Most problems are first layer to get this 100%, and bed not clean.

Bad filament is possible, or filament with water inside.

Move extruder to the top and extrude filament, it should go straight down(if not, nozzle possible blocked),

it should be thick enough(if not, nozzle possible blocked, or partial blocked), (do a cold pull),

if Bubbling during extrusion then it has to much water inside.

Check after the first layer is ready, then you see if it sticking enough, and not releasing and sticking to the nozzle.

If you see white spots like a bubble on the bed, then filament is releasing from bed.

Also no gabs between lines should be visible.

Use 7x7 calibration for first layer, see settings in the printer.

Search for " 3D printer first layer problem Calibration process" on youtube, movie on first layer calibration, with a good zoom in.

RE: First layer print troubles

RE: First layer print troubles

Hi Im having issues regarding bed adhesion.The first few layers stick perfectly and the print can run up to two hours before loosing adhesion and moving the entire model 🙁Does anyone have any advice? ive tried cleaning the bed and raising the temperature to 90 degrees, but the geometry still loses adhesion mid printLooking forward to any advice!!

Have you done the My Way (or equivalent) Z calibration test?

RE: First layer print troubles

@jsw

Yes and that all works and looks good for the first few layers. The print then just gets detached after a few hours :/

RE: First layer print troubles

@jsw

Yes and that all works and looks good for the first few layers. The print then just gets detached after a few hours :/

If you're confident that the plate is really truly clean, I might suggest a next step of something like that Bed Weld adhesive discussed in other threads. I know first hand that it really works.

RE: First layer print troubles

@natalie-alima

Print a big first layer on the bed, make a good picture, and let us see, no holes allowed, and white spots, there the filament is not sticking.

Did you try different filament?

RE: First layer print troubles

Hi Natalie,

what filament are you using?

I print PLA at 70C bed temperature.

can we see a picture of your first layer on a model with a flat bottom please?

are you using the 7x7 mesh beb levelling option that you can select using the LCD Menu?

Are you still using the Prusa First layer calibration option? I find it a poor tool...

I use a 75mm square 0.2mm thick patch and adjust Live Z whilst it is printing

I use the "Life Adjust 'Z' My Way" process.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First layer print troubles

@peter-m26

Thanks for all the advice I will try some of that out! However, I feel that my issue isn’t bed adhesion, but more to do with how the filament always strings up onto the extruder for some reason, it’s doing this every time right now and it’s meaning I can’t print anything. I’ve done cold pulls but I couldn’t see any debris or difference afterwards.

RE: First layer print troubles

@austc23

Move extruder up to 150 mm, and extrude by hand, if you see bubbles, then there is water inside the filament, look if you can see if it is thick enough(partial clogged if it is ti thinn), it should also come out in a straight line.

If it strings up , check if the nozzle is not to low or to high, or a partial clogged. And try a different filament.

Nozzle change is 10 minutes, and you now if it is the problem.

RE: First layer print troubles

@peter-m26

Will do, the filament may have had air in it as I did see some issues like that, will swap out the filament and try your suggestions

RE: First layer print troubles

So I’ve changed the filament a few times, extruded by hand and used the accu needle to try and dislodge any particles in the nozzle tip, I’ve also ran some more cold pulls. I managed to get one print going after leaving the filament to ooze out for 15 mins before starting the print, but again afterwards I can’t get anything to print successfully because it strings and doesn’t catch, gonna try cleaning the bed again properly with dish soap but not much else I can really think to do at this point

RE: First layer print troubles

Hi,

Since you seem to have done the basic trouble shooting with no fixing it, this does begin to sound like it could be a mechanical problem. Recently, I kind of had the same issue of prints being being knocked loose. It was not every time and it seemed to affect taller prints the most.

I removed the print cooling fan and the fan duct for it in an effort to see if the was anything sticking to the heat block. What I found instead, was the fan duct had one end sag just a bit and it was catching the prints and pulling them loose. It didn't even cause a "crash detected" error.

I printed a new fan duct from ABS and haven't had a problem since.

RE: First layer print troubles

Can you provide a good clear picture of the bottom of the benchy?

RE: First layer print troubles

hi guys,

Thanks for the responses.

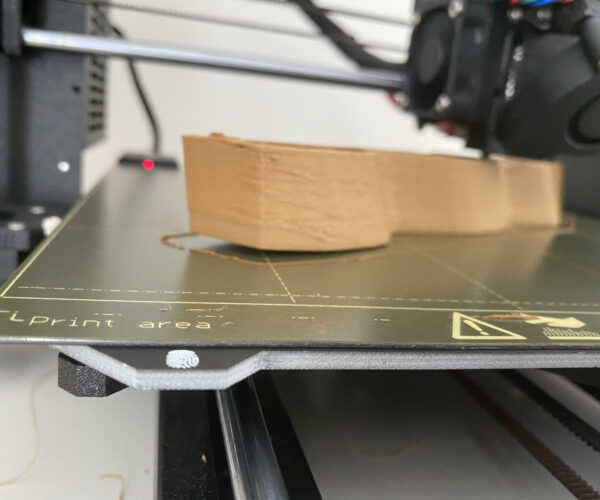

In my case. The print extrudes and sticks well to the bed. However after a few layers the model begins to peel off the bed. Images attached.

I have cleaned the bed with soap + water + Methylated spirits and added a bit of hairspray.

Bed temp : 90

Nozzle: 240

Z axix: - .650

speed: 90

Any suggestions why this happening/ how to fix it??

Thanks in advance!

@peter-m26 @bobstro @charles-h13

RE: First layer print troubles

@dalee1002000 I had the stock fan shroud start to droop as well. I assume the original was ABS, but I figured that something higher temp would be better, so I ordered a spool of the PC Blend and used that. I figured that if I just used a replacement one of ABS, it would eventually droop about as badly as well.

@natalie-alima In your first photo above, if that were my print I would try using some of that Layerneer Bed Weld adhesive or, lacking that, a small amount of glue stick. I'm assuming here that the bed is really most sincerely clean and that a 'My Way' or similar Z calibration was done successfully.

RE: First layer print troubles

@natalie-alima

Hi,

You gave us 97% of the information we need : ) what filament are you using? It's hard to tell from the photos you provided, but I would guess the first layer isn't being smooshed down enough still. Can you provide a good photo for the bottom?

RE: First layer print troubles

@natalie-alima

Print with a big brim attached to model 6 or 8 lines.

Use glue stick so model sticks better.(or other sticking material).

Clean bed with dish soap, and then print.

First layer should also be 100% correct.

If this does not help, you could try to print with higher temp, 10 - 20 degrees higher, and let no cold air hit the print.

RE: First layer print troubles

@natalie-alima

Hi natalie,

looks like some sort of wood fill stuff you're trying to print there, just for those who nag about missing information 😉

Overall it seems a typical case of warping to me. I'm sure there is heaps of stuff around to help with that. But just two ideas I would like to throw into the discussion (and I would appreciate if somebody more knowledgable than me could confirm or explain where I'm wrong).

Warping as such is a bit of tug of war between the printed object sticking to the built plate and the object contracting during cooling (pretty much everything does that but some materials are more notorious for it, e.g. ABS or ASA). As soon as the contracting forces get stronger that the sticking forces -> pop off the plate it goes.

So one thing to to do is obviously make the "sticky" forces stronger (clean built plate and good z-adjust, as mentioned above).

The other thing that needs to be taken into account then are the forces that bend the object during cooling. Grossly oversimplified the more material, the more shrinking. Yes, it is oversimplified, but I hope it helps to illustrate. So printing with as little infill as possible might be a first step in the right direction. The other consideration, and this might be part of your problem trying to guess from your bottom image, is the direction in which the forces work. It looks like your main warp is along the direction of some of your infill (the long bars of infill that go along the main axis of your print). This probably results in a proportionally stronger force along those bars when the material shrinks.

Hence maybe considering a different infill pattern might be of help. I personally have acceptable success with using the gyroid pattern, it seems to dirstribute the shrinkage forces more evenly through the printed object.

And in case you haven't found it yet and are keen to learn, bobstro's "random notes" on 3D printing helped me a lot to understand the whole thing a bit better: http://projects.ttlexceeded.com/3d_printing.html

hth

Hansjoerg