First layer not constant in time

Hi everyone, I have been trying to setup my MK3S perfectly without success yet. I followed the standard wizard and did the live z adjustement until it was right. Then, I discovered this auto incrementing gcode and used it to be perfect. Finally, I went with the bed leveling test gcode to adjust the sides of the bed. With the last one, I discovered that my Z level seemed too high in the center...

Which is odd because it was perfect before when using the auto increment gcode...

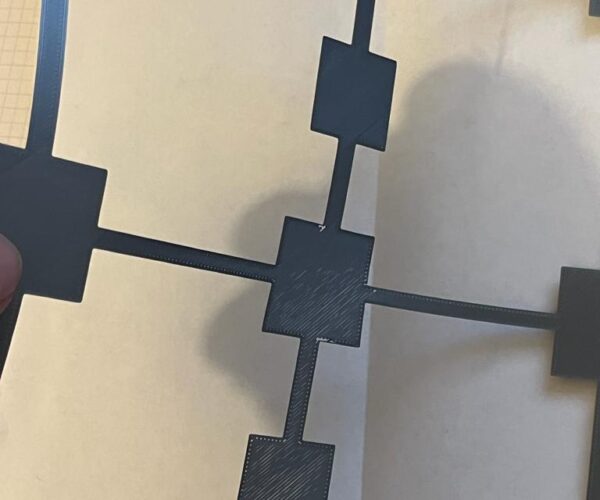

So I tried to print only the square from the center

Which came perfectly, or even with a Z level a bit too low I would say.

Then I tried to print the same square but with the one attached to its right. Again, no issue with the square printed in the center of the bed.

Then I tried to print the same as before but with one more square attached. Here we have the same issue, it is like the Z level is too high.

What is the problem here?

The square is always printed at the same location, meaning it should not be a problem with the Z level. Since the square at the center is always the last part to be printed, the only thing that is different when starting to print the final square is the printing time. Is it a temperature issue, getting lower and lower while printing? Or does it affect the PINDAv2 probe? Or an issue with the extruder as more and more material are used? Honestly, I have no idea.

Thank you for your help on this !

RE: First layer not constant in time

PINDA is only used for mesh bed levelling, not during printing. So no issue there if it heats up during printing. It is a good idea to let it heat up a bit before starting mesh bed levelling (a print) because it does matter if it heats up significantly during that…

You probably screwed up your nicely calibrated first layer with the bed level correction.

My recommendation would be: do a factory reset, run the wizard and the first layer correction (use the auto increment code if you please) and than leave it there. The bed level correction is normally not needed with a new original PEI sheet. It compensates for deviations in the coating thickness which PINDA can not sense (it‘s triggered by the metal).

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First layer not constant in time

are you using the 7x7 mesh leveling already? double check your heated bed, the spacers provided by Prusa are fairly consistent, so each of the 9 points should be screwed down to about the same tightness without overtightening so the spacers can do their job.

RE: First layer not constant in time

PINDA is only used for mesh bed levelling, not during printing. So no issue there if it heats up during printing. It is a good idea to let it heat up a bit before starting mesh bed levelling (a print) because it does matter if it heats up significantly during that…

It makes complete sense !

You probably screwed up your nicely calibrated first layer with the bed level correction.

Between the images of my first post I didn't change anything except the gcode printed. If what you say was true, shouldn't I expect to always get the same issues at the same location on the bed? Why bad bed level correction would sometime print the square at the center correctly and sometimes not?

My recommendation would be: do a factory reset, run the wizard and the first layer correction (use the auto increment code if you please) and than leave it there. The bed level correction is normally not needed with a new original PEI sheet. It compensates for deviations in the coating thickness which PINDA can not sense (it‘s triggered by the metal).

Will do !

so each of the 9 points should be screwed down to about the same tightness without overtightening so the spacers can do their job

What do you mean by "the spacers can do their job"? Are we expecting them to move?

RE:

What I did:

- Checked all the belt tension and lubricate the axes rods.

- Screwed the bed again following the manual recommendation for the order.

- Did a cold pull just in case the nozzle was clogged.

- Unscrewed and screwed the nozzle back to check everything is clean.

- Checked the extruder tension to grab the filament and its alignment.

- Started the wizard procedure and went successfully with a Z adjustment of -0.890

- Used the auto z live adjust gcode to pinpoint the z correction at -0.950.

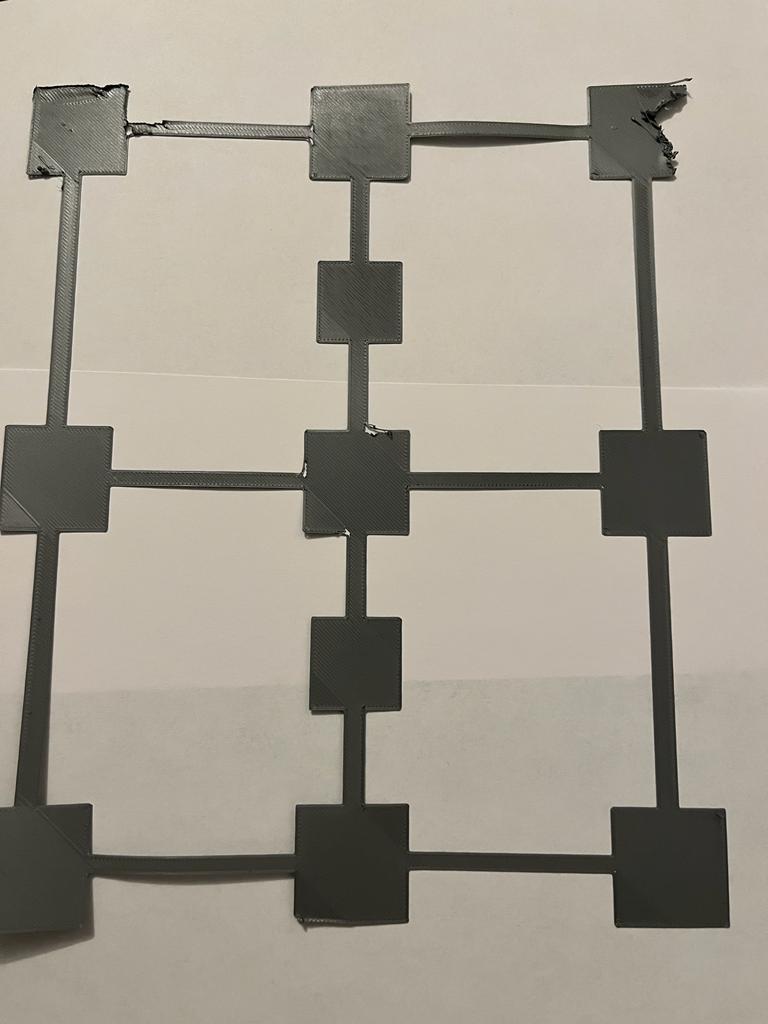

Now, printing the full bed gcode result in the following result:

A few observations:

- Even on the squares that seem perfectly printed we can see problems. For example, the middle-left square is printed in two steps and we can see the difference between the two areas that look like they have been printed with different Z corrections.

- Lot of issues for other squares as well where they are destroyed at some point...

At this point, I ordered new nozzles and upgrade to the SuperPINDA because it is the only thing left to check...

Any idea?