First layer issues

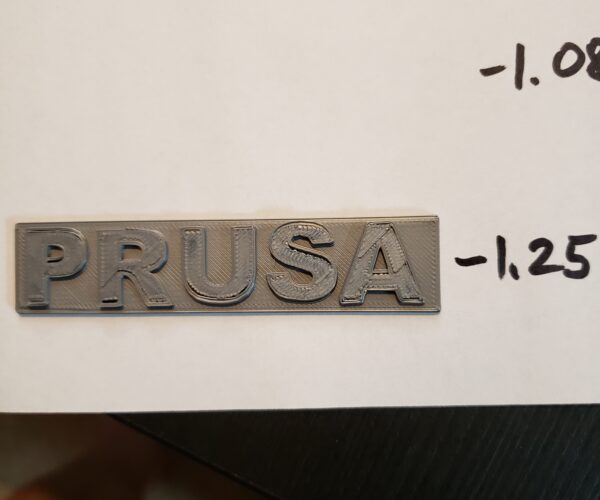

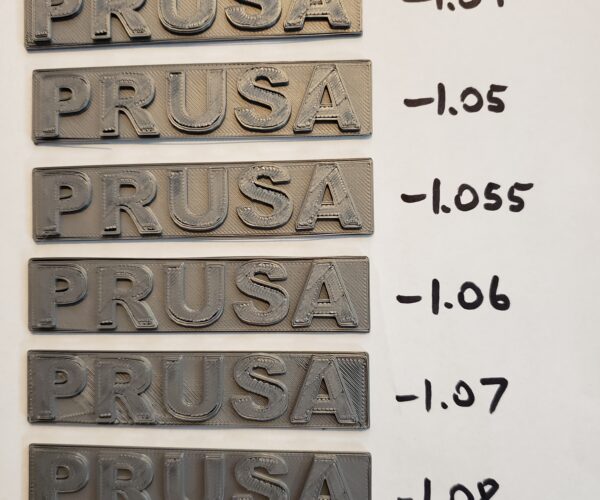

I finished assembly of my new MK3S+ and can't seem to dial in the first layer. It goes from not sticking when too far away (Z adjust -1) to not extruding when to close (Z adjust -2) with nothing acceptable in between. I tried printing the Prusa logo at different Z adjust levels and I've attached a picture of the results. I'm wondering if I've done something wrong during assembly.

First layer issues

I think there are 2 issues present.

First, the first layer isn't sticking very well (obviously). And second, it seems that the extruder is under extruding for some reason. See the Inside of the raised letters. The inside (top solid infill) is supposed to bond properly to the outer perimeter. Its not doing this and example -1.07 is under extruding the top solid infill layer too pretty badly.

Not sure if you have done this before, take your print sheet off and clean it with dish soap and sponge (no scratching) the idea is to get all grease and fat off so the polymer has a chance to stick properly. This is crucial before trying to set Z.

As a reference, my Z usually ends up around -1.5 or -1.4 something. So I think you still have some room to bring the nozzle closer to the printbed.

In case you did not know, you can also do a live adjust Z, that means you start a print job and while printing the first layer, you can adjust Z 'on the go'. Just start a print and while it is printing layer 1, push the wheel selector down a few seconds and it jumps into live adjust Z immediately. This is super handy and much better than doing it the 'official' way. I have done it MANY times.

Could you show us a picture like you did but from the underside of the prints so we can see the first layer.

First Layer Issues

Thank you. I'll clean the plate and try again. Is there maybe something I adjusted wrong, when I assembled it, that is causing the underextrusion?

RE: First Layer Issues

It looks like its not sticking properly. Except at -1.25 it looks better sticking wise but the bottom and top layers are whacked.

Since I do not have the Prusa logo file at hand, it is difficult to see what speeds it is set at. It is possibly too fast as well for your current tune. I sliced a XYZ calibration cube for your printer (MK3S+/0.4mm/PLA) with conservative speed and infill settings. Similar to what I use in production and the results are PERFECT.

I want you to give this gcode I added a try and see how it turns out.

First Layer Issues

Are having an extrusion issue also?

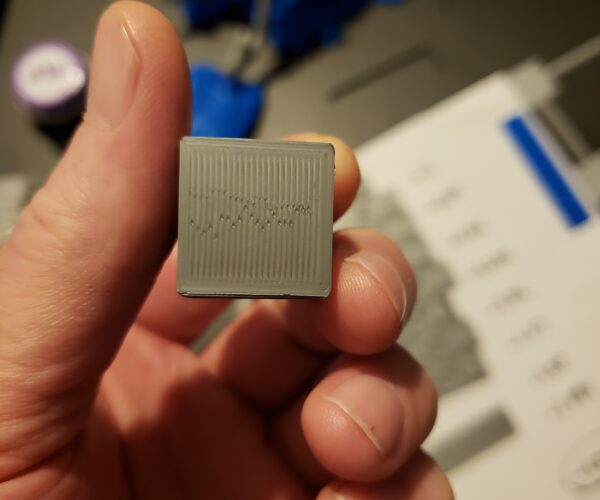

Its quite possible. The top solid infill layers are looking way too wonky and don't connect to the perimeters. The gap is there regardless of what Z he uses. I was curious to know what would happen if he prints my sample object with slow settings. I know those settings produce outstanding quality and I wanted to see what his printer does with that.

First Layer Issues

I'll start this print before I head to bed and post results in the morning. Thanks a ton for the ongoing help. The Prusa community is awesome.

Makes sense

Are having an extrusion issue also?

Its quite possible. The top solid infill layers are looking way too wonky and don't connect to the perimeters. The gap is there regardless of what Z he uses. I was curious to know what would happen if he prints my sample object with slow settings. I know those settings produce outstanding quality and I wanted to see what his printer does with that.

Let me know if I can help.

--------------------

Chuck H

3D Printer Review Blog

Grub screws

Also, check your grub screws. One might be loose or not against the flat side of the drive.

--------------------

Chuck H

3D Printer Review Blog

RE: Y axis loose

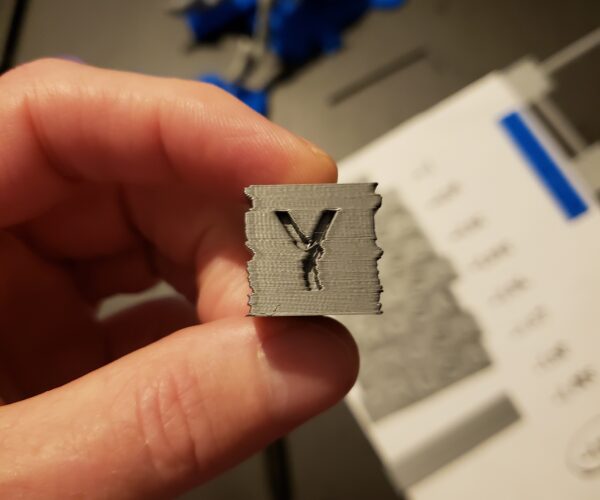

You are having severe Y-layer shifting. Once that is fixed, the Z and X side should improve as well.

There is a hardware issue on the Y-layer axis (printbed moving back and forth). Probably a loose Y-axis. Make sure that the little screw on the toothed pulley (motor side) is tight and that the belt is having proper tension. Also check that the carriage can move freely, it can be useful to disconnect the belt and push the bed back and forth and feel for resistance or binding.

Your Y doesn't suddenly 'jump' from one layer to the next but the transition is smooth/organic. My bet is on the motor pulley not tightened down properly. This would explain those constant/soft back and forth layer shifts on the Y axis.

Give it a check and print the cube again.

Edit : Here is a good prusa article about layer shifts. It covers other potential causes as well -> Prusa Knowledge Base | Layer shifting (prusa3d.com)

screws

Your Y doesn't suddenly 'jump' from one layer to the next but the transition is smooth/organic. My bet is on the motor pulley not tightened down properly. This would explain those constant/soft back and forth layer shifts on the Y axis.

One of the grub screws on the Y should be against the flat side of the drive. Check the assembly of the Y very carefully.

--------------------

Chuck H

3D Printer Review Blog

First Layer Issues

Thanks again folks. I'll do those checks and hopefully get the cube printed again before heading to work.

Good news.

The first screw you tighten is the one on the flat of the shaft. Than the 2nd screw.

If the first isn't straight on the flat it will work loose.

THANKS!!

Thanks again everyone for your help. Hopefully I can gain enough Prusa experience to help someone in the future.