First Layer height variances

Hey all,

Got my MK3 for a few months now and while it is working fine I seem to have some issues with the first layer.

It seems that when I do a Calibration test print the upper left corner of the print seems to be printed too high and you see light coming through the lines and in the lower right corner the surface is very rough which means that it is too low. Hopefully you can see it in the attached picture where in the corners the light does not seem to get reflected as much which is a rough surface.

So I thought it has something to do with an uneven bed.

Did the following things:

- Updated to 3.5.1 Firmware.

- Live Z calibration and made sure that the PINDA Probe is at least 35C hot, but made no difference to the variance

- Changed Filament from Amazon to Prusament with no difference

- Changed Slicer from Slic3r PE 1.41.1 to Cura 3.6 with no difference.

Note that Slic3r starts to print in the upper left corner and Cura from the lower right and they both show the same behaviour.

- Changed the bed leveling according to: https://github.com/PrusaOwners/prusaowners/wiki/Bed_Leveling_without_Wave_Springs and got it down to 0.022mm height variance according to the heatmap (attached). Even though the real variance between the screws is 0.01-ish but still I do get the same first layer issues.

So now I am officially out of ideas. What could cause this height variance between two corners and more importantly - how can I get rid of it?

I hope everything is understandable, if you need more information I will be happy to provide it.

Every help is appreciated and if you come around to Germany you can get a free beverage of your choice at my place 🙂

Thanks!

Re: First Layer height variances

Bed Level Calibration is supposed to help. It allows adjusting four points to "improve" layer one. You can set Front, Left, Right, Rear +/- 50um. I needed to lower the head 0.0015 inches on the left side so I plugged in -5um and saw zero effect. I increased the value and I am at -25um now and can see a slight improvement in fill. The trouble is the settings appear to interact a bit: changing left and rear affects the middle point.

What's really troubling is the simple fact the printer has a pinda sensor that is supposed to automate this, so that when you remove and replace the steel sheet, any anomalies are corrected. At least in 3.5.0 and later firmware, it seems the automatic bed correction is not working as well as earlier versions. I've downgraded from 3.5.1 to 3.5.0, and the issue persists. My next step is to downrev to 3.4.x to see if I can get back to a usable autocal.

ps: my intuition is telling me the PINDA is reacting to the density of the sheet metal, so if the metal is microscopically thicker in a spot the sensor thinks it is a high spot. I haven't tried flipping my sheet over to test this, but ... it's a nagging suspicion.

Re: First Layer height variances

I thought the same so tried flipping the sheet, made no difference.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: First Layer height variances

I would try the new 7x7 calibration that up on GitHub it work great for me. Just because the 9 points are level there still can be big changes in between. This firmware compensated for that and not only gave me a great first layer but Also a great top layer. Note I Also heated the Pinda to 30c before starting. Good luck I hope this helps. A lot more information at the link

Re: First Layer height variances

The evenness of your bed is not bad at all. What you need to do is adjust the Live Z level a little bit.

Start by washing the bed with detergent and water (no chemicals) so that the filament attaches properly.

It is difficult to look at the picture, but try to lower the Z level a little bit.

You seem to be very close to a perfect Z level, so there are extremely small adjustments that you should make. If it doesn't get better then you raise a bit instead.

Bear MK3 with Bondtech extruder

Re: First Layer height variances

How come everyone else seems to be able to get a flatter bed than me?.

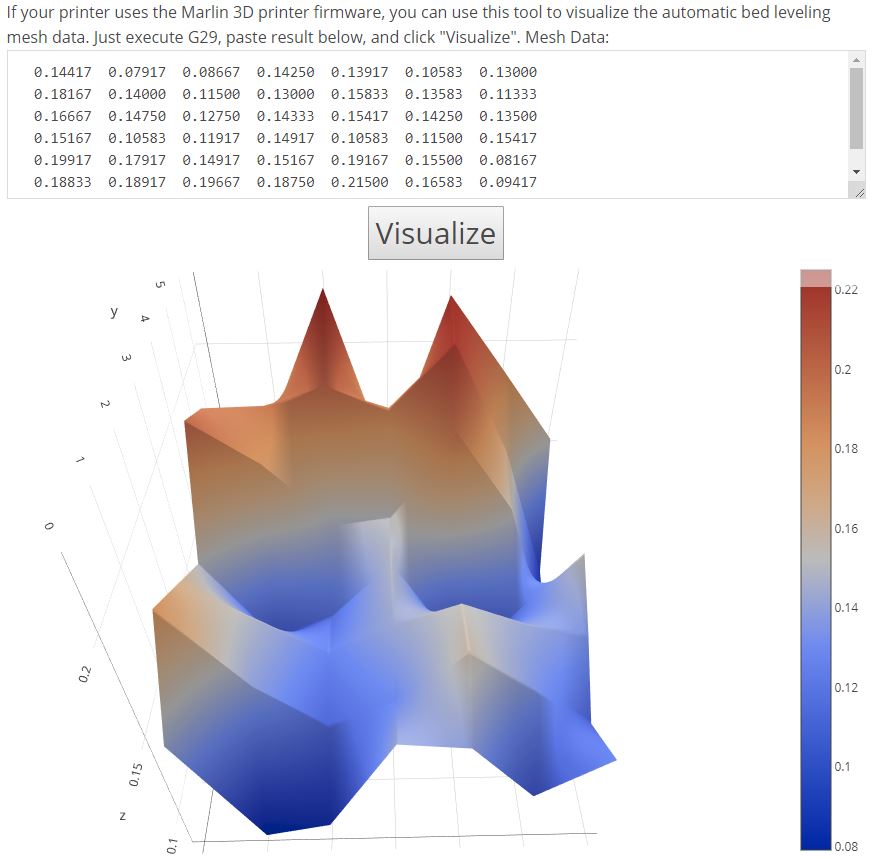

I flashed the 7x7 grid bed levelling firmware (Thank you john.k7 for the info about it) and tweaked the bed a little to get the 9 existing points pretty close, but the rest of the bed is all over the place!.

See below.

Admitedly, the first layer print is better with this modified firmware, but still far from ideal.

Here is the raw data from the G81 output.

0.14417 0.07917 0.08667 0.14250 0.13917 0.10583 0.13000

0.18167 0.14000 0.11500 0.13000 0.15833 0.13583 0.11333

0.16667 0.14750 0.12750 0.14333 0.15417 0.14250 0.13500

0.15167 0.10583 0.11917 0.14917 0.10583 0.11500 0.15417

0.19917 0.17917 0.14917 0.15167 0.19167 0.15500 0.08167

0.18833 0.18917 0.19667 0.18750 0.21500 0.16583 0.09417

0.15083 0.16833 0.22500 0.14333 0.22167 0.18833 0.15417

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: First Layer height variances

I flipped the PEI sheet and tried rotating it and still get the peaks and troughs the same, so suspect a warped heat bed, at least with this firmware the results are consistent unlike the original 3x3 mesh bed levelling and interpolation, those results are all over the place as the software tries to make sense of my undulating heater bed. So I would definitely recommend you try this modified FW.

Oh well, at least I have some results to speak to PRUSA support with tomorrow, since I have to go to work now.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: First Layer height variances

Hey all!

Thanks for the replies everyone!

Bed Level Calibration is supposed to help.

I have not yet tested it, as I have worked in the assumption that the Mesh Bed Leveling will compensate for any 50um variances in the sheet, but I will give it a try thanks!

I have flipped over my powder coated sheet, but the variances stayed the same.

I would try the new 7x7 calibration that up on GitHub it work great for me. Just because the 9 points are level there still can be big changes in between. This firmware compensated for that and not only gave me a great first layer but Also a great top layer. Note I Also heated the Pinda to 30c before starting. Good luck I hope this helps. A lot more information at the link

https://github.com/prusa3d/Prusa-Firmware/issues/1239

That is a great idea! It is worth a try and I will test it asap when I get the firmware to compile.

The evenness of your bed is not bad at all. What you need to do is adjust the Live Z level a little bit.

Start by washing the bed with detergent and water (no chemicals) so that the filament attaches properly.

Thanks for the suggestion. I do clean with 99.9% Isopropyl alcohol and I have played with the Live Z setting a lot. If I go any lower then the lower right corner loses adhesion completely and if I go any idea, then the upper left corner gets too high and also does not stick to be bed very well. So I think I pretty much have the perfect Live Z in my case.

How come everyone else seems to be able to get a flatter bed than me?.

Try this one: https://github.com/PrusaOwners/prusaowners/wiki/Bed_Leveling_without_Wave_Springs

It is a bit fiddly to tune it correctly, but you can get a relative nice and flat surface with that.

Please let us know when Prusa Support comes back to you 🙂

Thanks all again!

Re: First Layer height variances

Thanks for the suggestion. I do clean with 99.9% Isopropyl alcohol and I have played with the Live Z setting a lot.

I do not understand why so many believe that only Isopropyl / Isopropanol helps when cleaning the bed.

Isopropyl does not dissolve all dirt on the bed (fingerprints, glue stick, etc.).

By far the best cleaning method is detergent (hand dishwashing) and water. Isopropyl / Isopropanol can then be used between the prints.

Bear MK3 with Bondtech extruder

Re: First Layer height variances

Thanks for the suggestion. I do clean with 99.9% Isopropyl alcohol and I have played with the Live Z setting a lot.

I do not understand why so many believe that only Isopropyl / Isopropanol helps when cleaning the bed.

Isopropyl does not dissolve all dirt on the bed (fingerprints, glue stick, etc.).

By far the best cleaning method is detergent (hand dishwashing) and water. Isopropyl / Isopropanol can then be used between the prints.

Because it is recommended by Prusa as the "best option" here: https://help.prusa3d.com/article/6Gtws6Yqjg-pei-print-surface-preparation

Re: First Layer height variances

Because it is recommended by Prusa as the "best option" here: https://help.prusa3d.com/article/6Gtws6 ... reparation

What Prusa forgets to mention is that his recommendations apply to a pretty clean bed. For example, if you have used glue stick, you will have obvious problems if you try to clean the bed with Isopropyl or at worst acetone.

By our own and many others' experience, we know that detergent and water do the job 😉

Bear MK3 with Bondtech extruder

Re: First Layer height variances

I can get by with a wipe with a dry wipe between prints, 01%+ isopropyl alcohol wipe every few prints, 100% acetone every 2-3 weeks, and a dunk under the kitchen sink with Dawn as needed. I've dunked it 3 times since my printer arrived last April.

[...] I do not understand why so many believe that only Isopropyl / Isopropanol helps when cleaning the bed.

Isopropyl does not dissolve all dirt on the bed (fingerprints, glue stick, etc.).

By far the best cleaning method is detergent (hand dishwashing) and water. Isopropyl / Isopropanol can then be used between the prints.

What Prusa forgets to mention is that his recommendations apply to a pretty clean bed. For example, if you have used glue stick, you will have obvious problems if you try to clean the bed with Isopropyl or at worst acetone.

Prusa is assuming you've been following their guidance and not using glue stick except for very sticky materials. Your bed should be "pretty clean" most of the time. We see a lot of posts here from people who've read online articles, then start gooping their bed up with glue stick, hair spray, window cleaner, tape and other nasty (and usually unnecessary) stuff. "Avoid touching" eludes a lot of people for some reason. In those cases, I recommend the sink as the "Start Here" step just to be sure. The real point I try to get across is that touching the bed is a big part of the problem. Avoid that and you will make fewer trips to the sink.

Tom has a YouTube video in which he shows applying a bit of glue stick, then spreading it about using alcohol before printing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: First Layer height variances

Update time!

Tried a few things over the last day:

- Gave the Powder Coated Sheet a good rinse with detergent but with no difference in first layer quality.

- Flashed the 7x7 firmware and did a retest and my wonderful 0.036mm Bed Variance went up to 0.153mm.

A test print with the new firmware showed a much, much better First Layer but it seems that either my right side is too high or my left side is too low. Used the 5x5 Bed level Test STL from the Github and the squares on the left have a bit of air between the lines.

- To compensate for the left side being too low I tried the bed level correction feature and gave the left side a full 50um extra but interestingly it did not made any difference whatsoever. Does this setting get ignored over the last couple of releases or does anyone have an idea why it made seemingly no difference?

- As I am using the bed level method without wave springs I had the idea to just give the left side another 0.1mm in height and hope that even with mesh bed leveling it would made that side a bit better. But no, even with now a bed variance of 0.237mm the left side is not sticking very well.

So yeah, it has gotten better but its still far from perfect.

I am now thinking of somehow raiting the left Y rod but I am not really sure how yet.

You guys got any ideas? 🙂

Thanks!

Dennis

Re: First Layer height variances

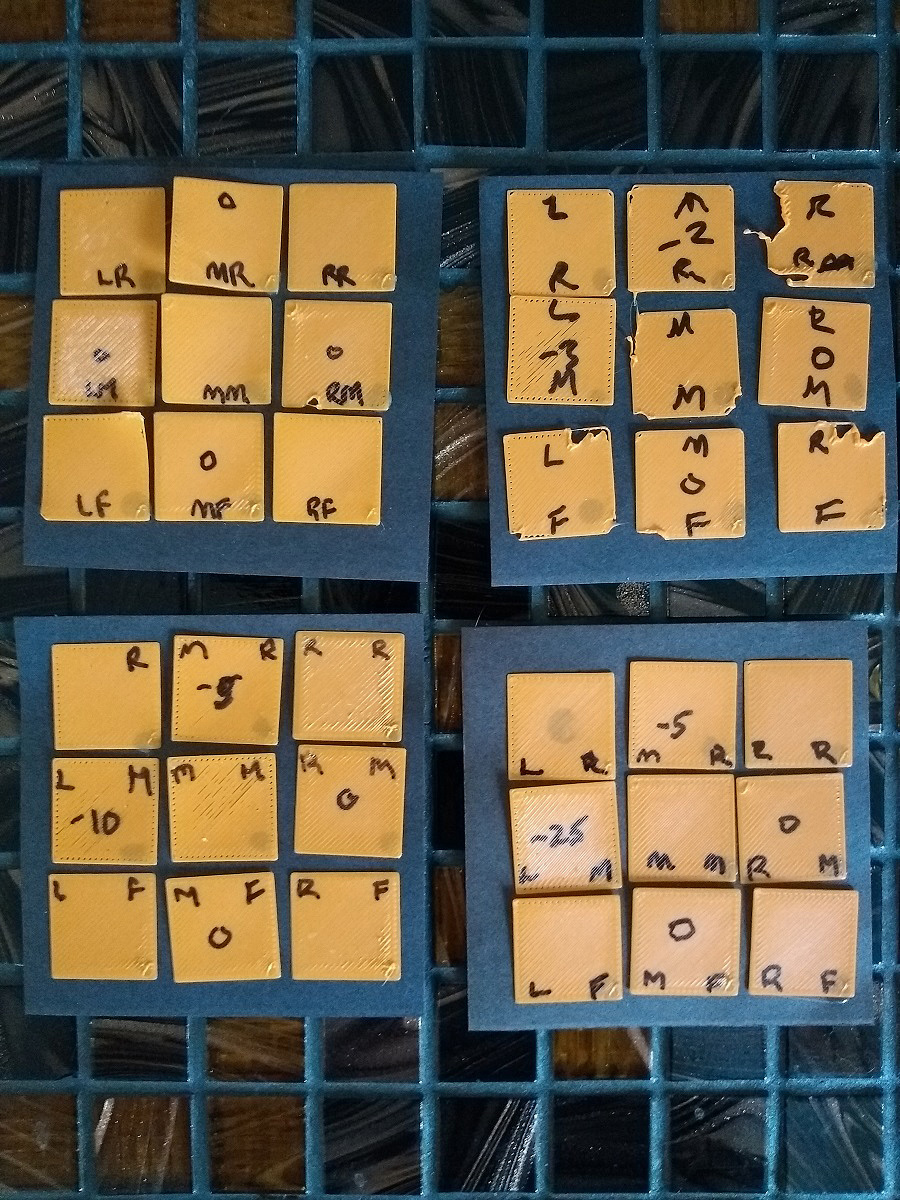

I also tried 50um adjust. It failed miserably. However, going from 0, to -5, to -10, to -25 did show improvement; as shown here. The front could probably be tweaked up a bit... but I was close enough I stopped (all tabs measured 0.008).

Note that at the -10 setting the middle tab showed signs of being too high, even though it had NOT changed. I suspect there is interaction between settings or I hadn't let the PINDA warm long enough.

ps: the torn up spots were caused by a bra that was dropping off the heat block and catching the filament.