First layer calibration issue

Can someone please tell me what happened?

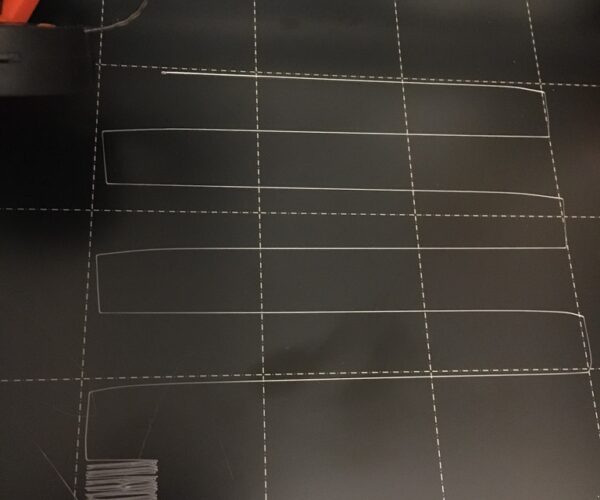

my first print layer is wavy on the corners and looks separated on the square.

I cannot adjust he z-axis as i have the screw screwed almost all the ways in after cracking the x-axis housing I had to unscrew so my printed housing would'nt completely break off.

I have tried to do the live z adjust but it only makes negative adjustments.

I have lowered the extruder to where the paper moves smootly under the nozzle and the pinda is pretty firm on the zip tie when I lower it.

Can someone tell me which axis is causing this and should the nozzle have a little hold on the paper rather than freely moving under the nozzle, as i know the nozzle does not need to drag on the plate, but i do not think lowering the pinda anymore will work as it already has a good pressure on the zip tie when I push it under the pinda.

Any help is much appreciated.,

RE: First layer calibration issue

Mr B,

Live Z only uses negative numbers.

the Pinda sets a nominal displacement between the X carriage and the build plate, that is bigger than you actually need, then liveZ adjustment lowers the X axis from the level set by pinda, to the actual level required to get a good squish on the filament,

You probably need to re adjust your Pinda, relative to your nozzle then re run Live Z calibration.

If you are currently using 9 point mesh bed leveling, activate the 7x7 (49 point) mesh bed levelling using the LCD menu.

Search the forum for Jeff Jordan's 'Life Adjust Z, My way' and use the zipfile at the bottom of the first post. this process is easier to get success with, than Prusa's lirst layer calibration tool.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First layer calibration issue

joantabb

Are you saying that if I calibrate according to the 7x7 levelling and then print the file according to jordan's suggestion it will work.

I will have to try this when I get back home because I am away on work.

Thanks for any follow up.

RE: First layer calibration issue

most people get success with that process.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First layer calibration issue

Looking at the picture, It looks like a LiveZ adjustment issue. I recently went through this and can't say enough about printing the squares ( Jeff Jordan's "My Way" )

This along with temperature towers will help you dial in your machine to filament specifics. I had great success, then failure after failure. Taking the time to print the squares, REALLY helped. I use a textured surface - so I also had to figure out what worked for us to get decent adhesion.

PLA - Windex the surface

PETG - Isopropyl Alcohol

ABS - Isopropyl Alchohol

- AND if prints have small surface area - use a smear of glue stick. ( mild dish soap removes this after the print is finished )

RE: First layer calibration issue

@1humshark

1humshark common sense is not one of my best abilities, so please excuse me. When you say you had these same issues, did you start printing the square and? As the square was printing you made adjustments so gradually the square became more defined to a perfect square. Is my thinking right or am I wrong? If there were a video showing this happen in real-time would be great. Also when you mention pla- windex the surface, do you mean that in an adhesive sense or easy removal sense. Again I apologize but I have adult adhd and if you are not detailed my brain questions back and forth so that I will doubt myself. It is a burden I must carry for the rest of my life.

Thank you for your response.

RE: First layer calibration issue

@mr-b

Hi MrB

this is a video... that covers the setting of Live Z using the Prusa first layer calibration.

This video uses a calibration square... apart from the printer being what looks like a Bear or Zaribo derivative, it is similar to the mk3

the demonstrator, is, in my opinion very verbose and a little difficult to understand... but it might help you

he insists that the changes need to be done in 20 or 25 micron increments, this is not critical,

similarly he suggests that the live Z should be between -.400 or -.450 and -.900 or -1.00. the range of acceptable values can be larger than this...

As the demonstrator says, every printer will end up with a slightly different value of live Z in order to achieve the preferred adhesion/squish.

so don't stress about achieving a particular number for your live Z

while you watch the video's please note the first video uses a 'Stickered Build plate' and the second uses a 'Textured powder coated Build Plate'

Both work on the prusa, different people have preferences and different success rates. In My opinion cleanliness is the key to pla adhesion... other folk have different opinions. the absolute BEST solution, for you, is what ever works consistently, for you!

also note, the first video uses 9 point mesh bed levelling (3x3 mesh bed levelling) and the second uses 49 point mesh bed levelling. (7x7 Mesh bed levelling) I find greatest success with 7X7... (this is selectable using the LCD Menu on recent Mk3 firmware!)

Also note, if you have more than one build plate, the 'best' Live Z adjustment may vary between them particularly if you change between a stickered build plate and a textured build plate, the textured build plate is thinner than the sticker version so your best live Z is likely to be a larger number for the textured build plate. (latest firmware has the ability to remember a number of live Z values to address different build plates. bu it is up to you, to do the initial adjustments, and to ensure you are using the correct setting for the correct build plate.

also note, if you change filament from pla to petg or abs, then the best live Z may change because the temperature ranges are different, leading to differential expansion of various parts... which may affect the Live Z setting.

I hope this helps,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First layer calibration issue

@joantabb

Thank you for putting a link to the video. Now I understand that it will vary and I do not have to worry about trying to get a positive number only negative. I want positive adjustment I just need to adjust the pinda I think?

I see now to test the adhesion with my finger as in the picture.

Thank you again.

RE: First layer calibration issue

Rule of thumb: Once you set the PINDA and it calibrates - never touch the PINDA.

It only sets the distance between the nozzle and the PINDA. Everything else is done with Live Z calibration.