Re: Filament tip problems.

forget it, PJR handled it

I tried fine tuning the settings but it doesn’t work on mine.

Re: Filament tip problems.

My next step now is to replace original MK2.5 heatbreak with MK3/Multimaterial type.

Re: Filament tip problems.

PJR also mentioned in one of his posts that he changed out the PTFE tubing for ones that had a larger tolerance if the tubes are bigger in diameter they could offset the mushroom and allow the filament to flow freely back and forth with a wider tip

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Filament tip problems.

PJR also mentioned in one of his posts that he changed out the PTFE tubing for ones that had a larger tolerance

Yup. I have Bowden and filament feed tubes which are 2.5mm ID. Not sure if its that or removing the lower Festo that solved my problems - I made both changes at the same time.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Filament tip problems.

Update: No more jamming on my extruder after replacing MK2.5 heat break with MK3. Before installing the replacement, I insert all jamming tips and noticed that I can go in freely. Diameter of MK3 heatbreak is confirmed bigger than the one originally installed on my MK2.5.

My MK2.5+MMU2.0 is currently running almost 2 hours without jamming.

Re: Filament tip problems.

Managed to complete 15x15x10 cube with zero jamming and zero layer skip. Before I couldn't complete even 3mm high without skip and jamming. Big improvement on my MK2.5+MMU2.0.

Re: Filament tip problems.

awesome, now the sad part is 2.5 users are kind of getting screwed here as they need the 3 heatbreak

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Filament tip problems.

It's my 2nd batch of cubes and still no issue. What a relief. I'm going to print lizard or benchy tomorrow.

Re: Filament tip problems.

There is one thing I forgot to mention. I am using the default filament and printer settings.

Re: Filament tip problems.

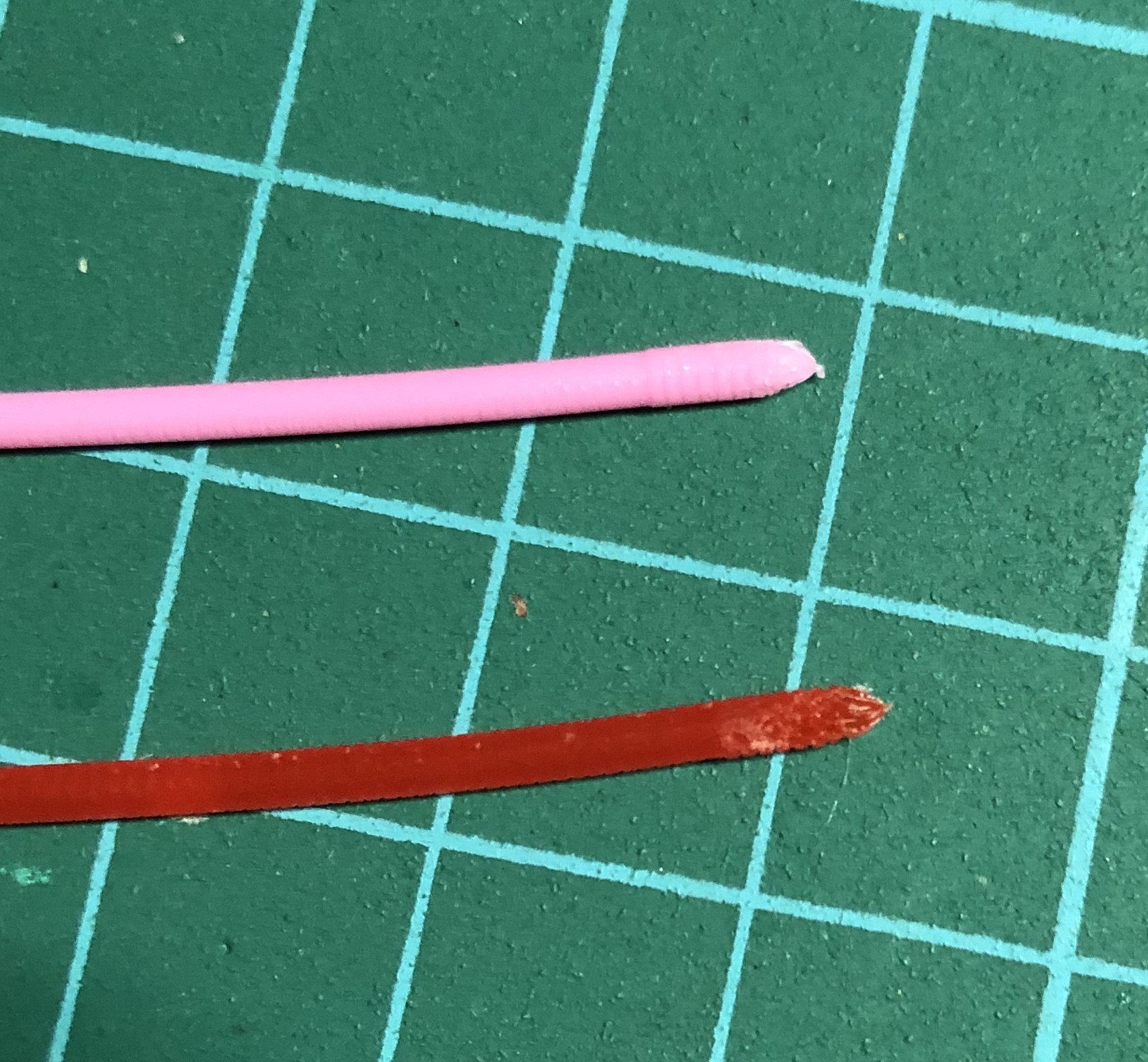

Thank you for this thread. I'd put in a 3rd party, ebay, heat break after mine bent on a over night failed print. The replacement had been printing fine for 6 months before the MMU install, however I've been fighting fat tips for the last 3 weeks since I"d gotten the MMU. I finally remembered after reading this thread again that my heat brake was not stock and I pulled it out and sure enough it had a smaller diameter. Its tough to measure but it is not much bigger than the 1.8mm filament and the 2.0 to 2.1 mm tips I'm getting are not going to go back into it.

Figuring I had to replace it anyway, I just drilled mine out. I kind of thought that my tips would get bigger still with a larger bore so looked for a drill bit in the 2.1 to 2.2mm range. The bit I used has no markings but it measures 2.3mm with a couple different calipers.

I'm still on my first print but I'm 50 tool changes in with no jams at all, that is a record. My tips have stayed the same size to gotten somewhat smaller in the 1.9 to 2.1 mm range with far more down at the 1.9 end. There are some physics going on there that I don't quite understand....

I'm hopeful I've finally got the the root of the problem. This may need to be put on the list of things to check.

I3 MK3 MMU 2.0.

Re: Filament tip problems.

I'm having no luck with my mk2.5 and mmu2. Seems to be no combinations of settings that get me nice string free tips. I get tons of jams and skipped layers. I've quadruple checked there are no hang ups or unesessary friction. I think I might try this heat break thing next.

Is anyone on the mk2.5 having luck without this swap? Or is the only people having success on mk3's?

Re: Filament tip problems.

My MK2.5+MMU2.0 running without jam for 3 days after replacing my heat break to MK3 type.

Re: Filament tip problems.

I gave the mk3 heatbreak a try on my mk2.5 but unfortunately it didn't change anything for my tip issues 🙁 I do however have a mmu2 now for the MK3 I keep at work so I'll see if anything is different there soon when I get around to building it.

Re: Filament tip problems.

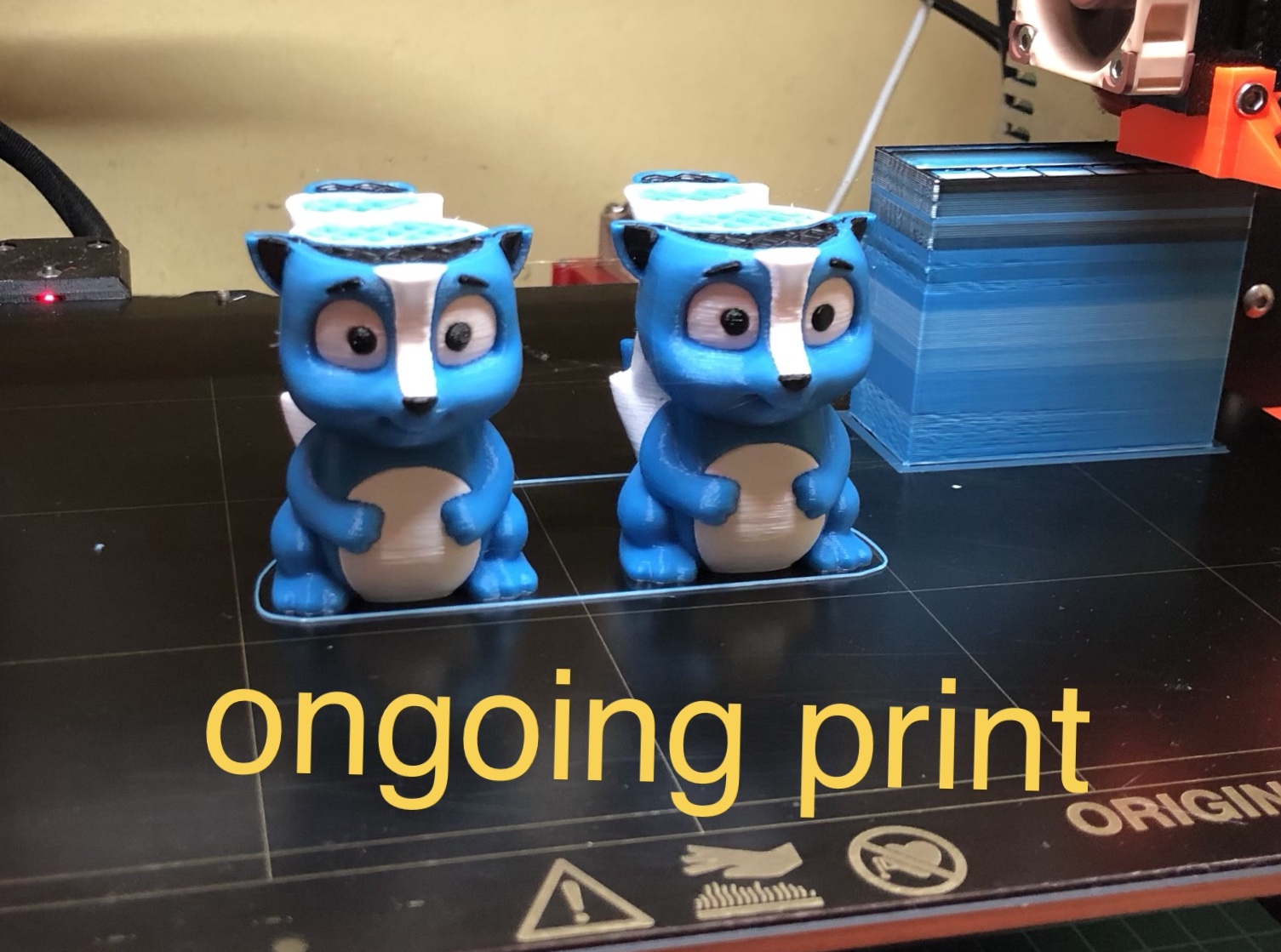

After I replaced heat break with MK3 type I used the default printer and filament settings. I already printed a lot of 3-color key chains for Christmas give aways and 1 large lizard without any jamming. I'm currently printing 2 pcs 3-color skunks (~16 hours) and with remaining 2 hours left.

Too bad I already bought Mosaic Palette 2.0 and just waiting for shipment.

Re: Filament tip problems.

I gave the mk3 heatbreak a try on my mk2.5 but unfortunately it didn't change anything for my tip issues 🙁 I do however have a mmu2 now for the MK3 I keep at work so I'll see if anything is different there soon when I get around to building it.

I might have been premature in my assessment of this heatbreak not working... I just gave it another shot and made sure to use all default prusa settings for PLA and the tips came out perfect with no strings! I don't really understand why this worked but it looks like it did! I'm quite surprised. I'll see if I can get an actual print to work now without failing.

Re: Filament tip problems.

Kenny,

Make sure MMU2.0 to PTFE tube runs fine. Try to print multi material model or cubes with your PTFE tube disconnected to your extruder. This is how I did my dry run. Once no jamming, you can focus with the extruder.

Please note that enlarged filament tip and stringing should be dealt separately. If you have stringing, reduce the temperature on the affected filament only and you may want to save it for that particular filament.

I hope you make your MMU2.0 work on MK2.5.

Re: Filament tip problems.

Do I understand this right? You had two defective heatbreaks?

--------------------

Chuck H

3D Printer Review Blog