Filament getting stuck upon removal

After the 3.2.1 upgrade I can no longer unload the filament with out it getting stuck between the gears and the upper PFT tube. Each time I have to open the housing with the gears, pull the filament, cut and then remove. Any recommendations?

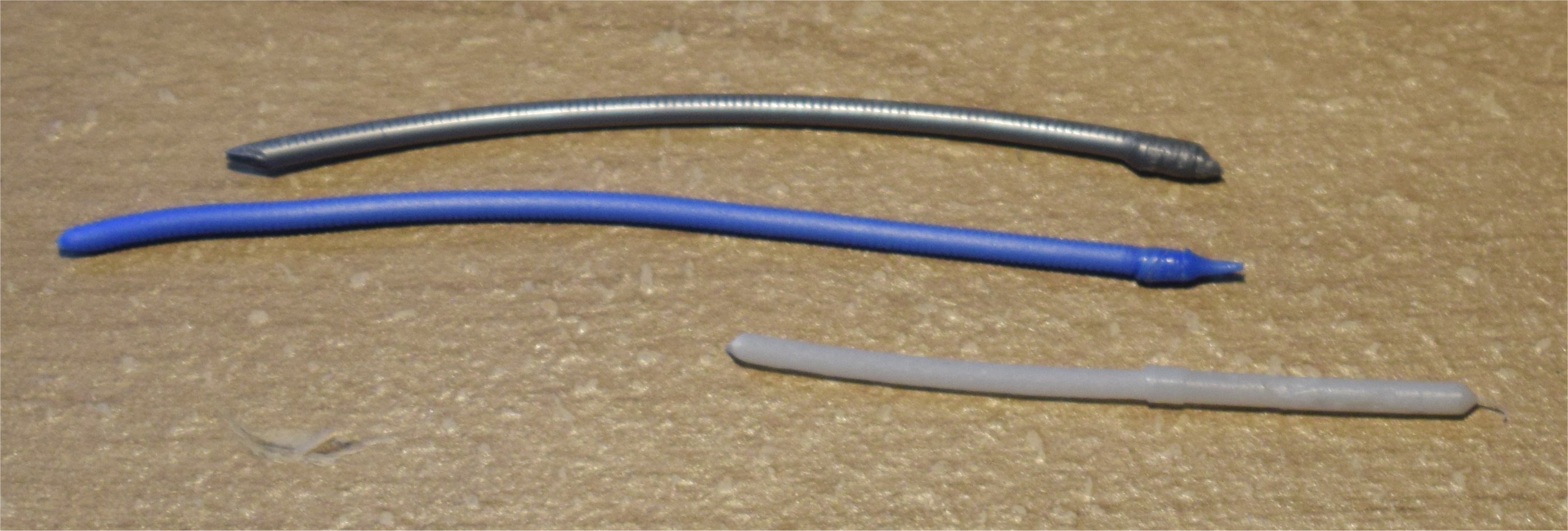

Below is the glob that is getting stuck.

Re: Filament getting stuck upon removal

I do not have to go to that "extreme" but when I unload filament, I always end up with a tiny blob at the bottom which makes it harder to pull out.

Re: Filament getting stuck upon removal

same problem for me.

I have to open the housing with the gears, pull the filament, cut and then remove.

Re: Filament getting stuck upon removal

I've never had to disassemble anything to get the filament out but yes, it's often difficult to pull out of the top tube after the reverse feed runs. I'm not sure how that blob gets created.

Re: Filament getting stuck upon removal

The blob is formed by material being pulled up from the heat break still being hot when it hits the gears and the tensioning springs set wrongly. It can be seen in your photo that the teeth dug deeply into the hot filament when pulling it out. I have found it is best to unload at the bottom end of a filaments temperature to avoid this problem. That way is just hot enough for the bottom of the PTFE tube to reshape and pass the removed filament but it will be cold when it hits the gears.

2 Unloads and a Cold Pull

The top unload cutting was from Prusa Silver PLA. The middle one from my preferred PLA+. In both of those you can see a slight narrowing behind the blob which was formed as the unload started but as the filament quickly cooled as it passed though the heatsink no other features were formed.

The bottom one is a cold pull. On this several features can be seen. At the tip the nozzle cone. Working up a thin ring at the join between the nozzle and the hot end of the heat break. The next feature is formed by the heat break between in the actual heat break zone. This is the bulge that can form a blob. It is caused by a high extruder pressure pushing out on the very thin walls of the heat break resulting in a section that is more than 2mm in diameter. This is the bit that if it is still too hot when it hits the bears will cause the blob. The final section is raw filament, with out teeth marks as I was doing manual loading and unloading while cleaning the nozzle.

Possible solutions are turn the temperature down as far as possible that the extruder can still pull back at. Remember you are only trying to force the filament through 1.75mm PTFE tube not a 0.4mm nozzle so it does not need to be as soft to get through. Change your heart break for a titanium one as these are less prone to bulging due to higher strength.

Regards,

Martin

Martin Wolfe

Re: Filament getting stuck upon removal

Great tip. I’ll try next time to unload at a lower temp within range and see how it goes.

Thanks

Gaston