Failed prints after replacing the hotend

My printer has been printing fine for 3 years. A few months ago, a long print detached from the bed and caused such a big mess around the hotend that I had to replace it.

I took a spare hotend from a friend, it's an E3D v6 clone (24V) and replaced my dead one.

Since then, I can't reliably print anything. I'm suspecting the extruder idler tension, but I wanted to get more help on this.

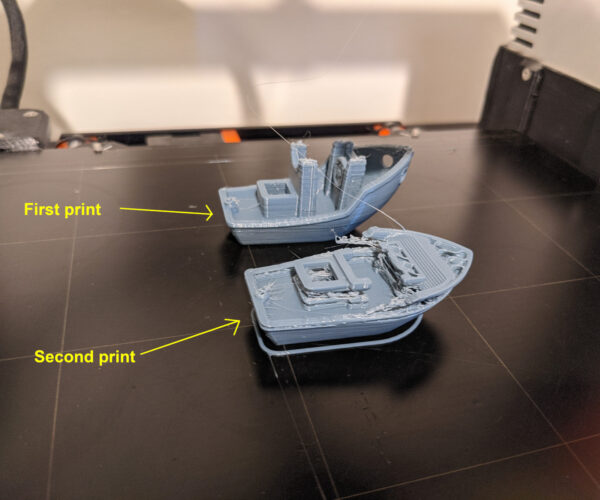

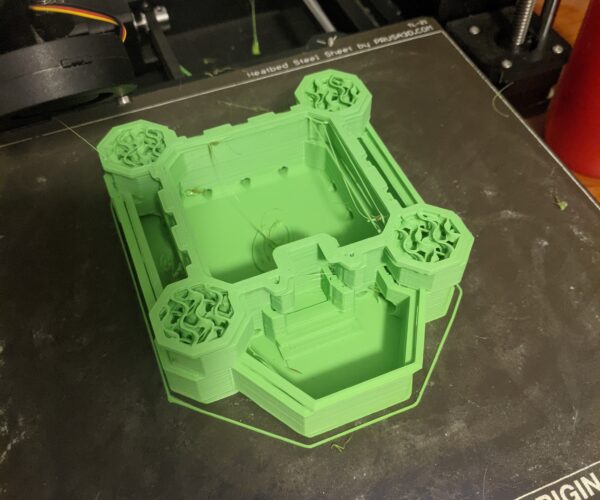

Here are two attempted prints (I just put the first one next to the second on the heatbed - they were printed a few days apart):

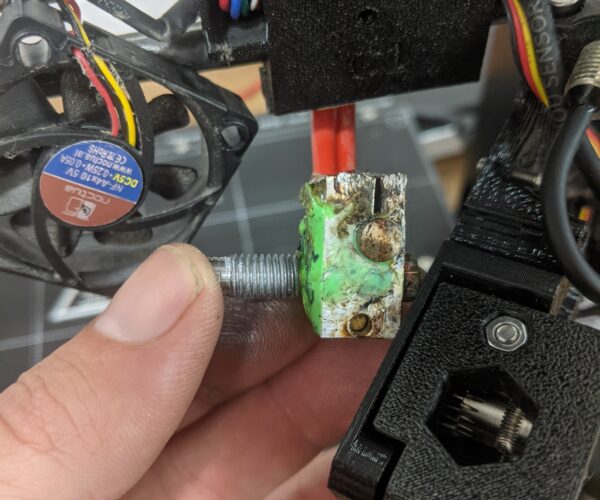

In the first one I tightened the idler screws to be flush with the extruder body. It printed well in the beginning, but after a while, there are a couple of layers where it seems less material is being pushed (see the 4 corners of the middle "house"), and then the filament started accumulating around the nozzle and hotend. Here's a closer look:

I decided maybe the idler springs are too tight and tried to find a reasonable explanation on how much to tighten them. I followed this video:

I eventually tightened the screws one more turn (each) because the springs felt very loose. This resulted in the "second print" above, where the print is fine for the first few layers, then it became spongy (minimal material extruded) and then it printed a few more good layers before I stopped the print. Here's a look from the side:

Any suggestion on what's causing this? I'm using OctoPrint, are there ways to collection more information (logging) to diagnose this?

Thanks.

RE: Failed prints after replacing the hotend

Is the filament popping when you print? It looks like extrusion issues and this can happened when the filament is wet.

--------------------

Chuck H

3D Printer Review Blog

RE:

^^^^ This ^^^^

Plus, how do things go when you try a simpler print, such as a calibration cube with a known-good dry filament? Those might better indicate the issues.

Remember that the Benchy (Boaty McBoatface) is intended as somewhat of a torture test.

RE: Failed prints after replacing the hotend

I tried printing using a brand new filament, but sadly, the results are very similar.

I never considered the Benchy to be a torture test (well, not for a Prusa), it's more of a quality check. Looking at the results, it's definitely an issue with short paths. It starts when the each layer has very short paths for the boat "house" (see below). Any other suggestion? Retraction settings? Temperature? Thanks

(Note: I stopped the print manually)

RE: Failed prints after replacing the hotend

You definitely having a extrusion issue. Dry the filament and see if it continues.

--------------------

Chuck H

3D Printer Review Blog

RE: Failed prints after replacing the hotend

Sorry, the last print was done with a brand new filament. It's definitely dry. Came out of a vacuum bag straight from the store.

RE: Failed prints after replacing the hotend

Sorry, the last print was done with a brand new filament. It's definitely dry. Came out of a vacuum bag straight from the store.

That is not definitive. It is probably dry.

--------------------

Chuck H

3D Printer Review Blog

RE: Failed prints after replacing the hotend

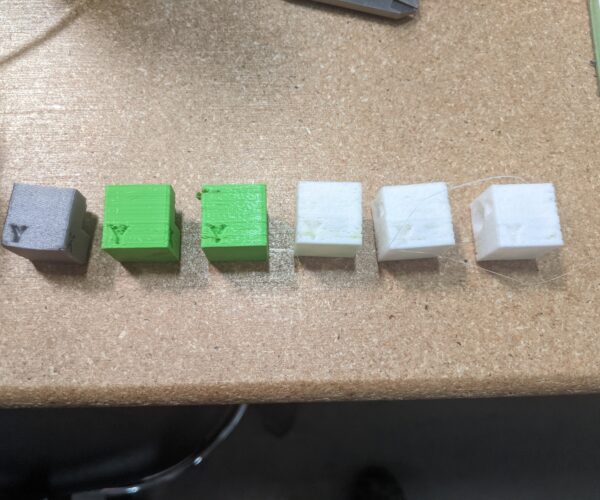

I am having the exact same issues regardless of the filament I use as well, I have noticed that over time its just getting worse and worse with each print. Granted I am tweaking settings between each print but nothing seems to help. I tried tightening the extruder, that didn't seem to work, tried reducing/increasing flow rates, that didn't work. What's funny is I swapped the hotend just like OP, calibrated Z and it looked great, I started printing and after about 6 prints I noticed a sever drop in quality for the same prints! When I get home I will post the pictures of my test cubes.

I am having the exact same issues regardless of the filament I use as well, I have noticed that over time its just getting worse and worse with each print.

Have you tried drying it? All of it?

Cheerio,

RE: Failed prints after replacing the hotend

It sounds like under extrusion. Try drying it and see what happens.

I am having the exact same issues regardless of the filament I use as well, I have noticed that over time its just getting worse and worse with each print. Granted I am tweaking settings between each print but nothing seems to help. I tried tightening the extruder, that didn't seem to work, tried reducing/increasing flow rates, that didn't work. What's funny is I swapped the hotend just like OP, calibrated Z and it looked great, I started printing and after about 6 prints I noticed a sever drop in quality for the same prints! When I get home I will post the pictures of my test cubes.

--------------------

Chuck H

3D Printer Review Blog

RE: Failed prints after replacing the hotend

I think we can rule out wet filament. I took my filament to a friend and printer the same model with the filament (it's the center "house" from 3DBenchy - didn't want to spent the extra time on printing the bottom area which print ok). Here are the results:

Again - same filament, same gcode, 2 hours apart on 2 printers.

It's definitely something with the extruder. The moment the paths become short (and there are more retractions), things get really messy and after a while, the extruder stops pushing the filament (grinds the filament). I wasn't near the printer in previous prints (they were longer). This time I stayed near the printer, and the when the paths became shorter, I started hearing the occasional tick from the extruder.

This article: https://help.prusa3d.com/article/extruder-noises_2013 seems relevant, but it feels like its more about something that happens all the time and not only (or almost exclusively) when the printer draws shorts paths with retraction between them (this is my understanding of the print problem I have).

Any suggestion? Thanks.

Your friend needs to check belt tension. The filament is damp.

Your print sheet is dirty, clean it thoroughly.

Dry the filament. Show us a dry print and then we'll have a better idea - but I suspect your fan shroud may need attention.

Cheerio,

RE: Failed prints after replacing the hotend

I know this is not that kind of forum, but I have to talk about feelings.

I feel great frustration. Whatever I do - take a new spool out of its vacuum seal, compare to the results on a different printer... the issue of wet filament keeps lurking back even though I clearly said "we can rule out wet filament". I compared my poor print to an "amazing" print on my friend's printer and the comment is to clean my friend's bed (and dry the filament...)? Why does it matter if the bed isn't clean if the print came out that great? (at least compared to mine). My friend hasn't printed anything in a few months and the heatbed had dust, we did a quick swipe, and it was good enough to stick. This was just to show that the problem isn't the filament - it's something in the printer. Isn't this obvious? What should I have said?

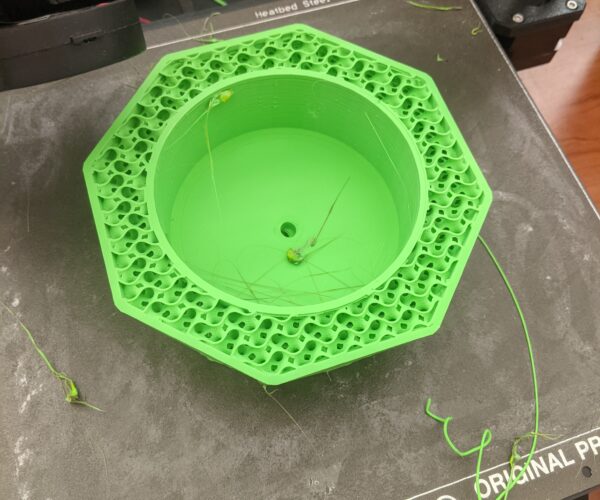

OK, I dried the filament. Now the results are much worse. Quite sure extrusion is messed up (maybe the hobbed gears are now completely clogged), I'm asking for some advice to shorten the path to fix.

The bottom image is the sample print after drying the PLA filament at 45C for 4 hours (the two top prints are the previous ones - for reference):

FTR, in >7 years of printing I never had issues with damp PLA. I would use a spool for months, and it was fine. Sure drying might give you an extra 2% in quality, but I don't need that. I need reasonable prints, which I'm not even close now.

RE: Failed prints after replacing the hotend

Did Your hot end have a new nozzle in it when you put it on??

Go read it again.

Your second print, without the interference of moisture, suggests you have a temperature/cooling issue. Check your fans and fan shroud. Show us a picture of your shroud in relation to your nozzle if you are unsure.

Cheerio,

RE:

Your original post:

My printer has been printing fine for 3 years. A few months ago, a long print detached from the bed and caused such a big mess around the hotend that I had to replace it.

I took a spare hotend from a friend, it's an E3D v6 clone (24V) and replaced my dead one.

It’s pretty safe (in my opinion), that it is your hot end causing the problems. If a printer works fine, then you change the hot end and then it shows problems that where not there before, this is not something you can fix by changing slicer settings. It’s a hardware problem of the hardware you changed. Not the idler tension, not the gears -they worked fine before, why should that have changed? Open the extruder, take out the hot end and check everything is like it should. You wrote it’s a clone, maybe it’s a crappy one. Maybe it’s slightly misaligned, maybe the PTFE is to short or to long or not inserted correctly and held correctly by the collet…

Do you still have the old hot end? Can you salvage parts? Compare them to the new one, are they exactly alike? Especially the PTFE?

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Failed prints after replacing the hotend

So I tried drying the filament, still didn't help, now I am having problems in the X direction and I am fairly certain the nozzle I put on this thing is not the right size or to spec. The globbing and burning is the worst I have ever experienced on any printer and I have gradually turned it down from 215 to 185 to try and fix that but to no avail. The hotend is absolutely covered in melted material so it must be squirting past/over the nozzle and onto the outside of the hotend. It's crashing into these burned globs and then on top of all of that now the X axis is messing up! I have fixed/repaired this thing for 3 weeks now and I don't have any money for parts anymore... This is a 0.6mm "E3d v6" nozzle from a variety pack on Amazon. It's past warranty now and TBH I have had so much trouble with this thing I would just throw it away and never print again but I have to print stuff for work so I am stuck with this POS.

You have a damaged fan-shroud, this is part of your problem. Replace it.

Either you have the incorrect nozzle, one with too short a thread (they are common and sometimes miss sold) or you have fitted your nozzle wrongly.

Pay particular attention to the diagrams at the bottom of this page:

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

Cheerio,

RE: Failed prints after replacing the hotend

Thank you Diem I will do that and actually follow the instructions when I replace the nozzle eventually

RE: Failed prints after replacing the hotend

Diem, how do you figure my fan shroud is damaged? I took it off and it looks fine, not damaged at all. However taking the hotend off I see that the nozzle is not spaced by that 0.5mm which might be the problem, I am soaking it in acetone right now to get all that material off. It appears to be leaking filament from the heat break itself. I am trying to print a new fan shroud from PolyCarb on the mk3s+ at work and now that one is globbing, aye aye aye these finicky things are driving me crazy 🤣