Extrusion issue

I've just finished my build, but can't do the first layer calibration due to under extrusion. That is, all I get is a very thin strand of plastic coming out of the nozzle, about 0.25mm.

- Extrusion starts out normal during the priming phase, but by the time it gets to the oblongs in the calibration, it is very thin 0.25mm

- It's not layer height because I can pass a sheet of paper between nozzle and bed

- I've checked the extruder mechanism, and it seems aligned

- I've cleaned the nozzle

- When I heat the nozzle and just run the extruder, the plastic comes out as I expect

It doesn't extrude enough when I do the first layer calibration, nor when I try to print a test object but will extrude sufficient when that's all I ask it to do.

I'd much appreciate any help on this; I don't know what to do next to track this issue down

Re: Extrusion issue

The lines printed in the live-z calibration are much thinner than the purge strip at the beginning.

Can you post a picture? Maybe one of the whole live-z print and one of the final square at the end, as close as you can get and still have the camera focus.

When someone asks you if you're a god, you say, "YES!"

Re: Extrusion issue

Thanks

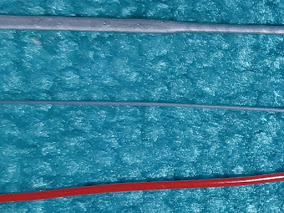

Sorry, hard to get everything clearly in on the shot, I didn't get the final square because it often comes out a blob. (Though this will probably be a Z height issue when it does work its thin lines that don't touch)

BTW: During the Z calibration exercise the corners are sometimes square, sometimes not, again a z height issue that I can fix once I solve the extrusion issue

The top example is from the edge of the bed, before the actual print. (Note the change in width, this happens about halfway along)

The middle example is taken midway through the print

The last example is for reference; it comes from my old printer

BTW: The extruder appears to be working the whole time, and I can't hear any clicking

Many thanks

Re: Extrusion issue

Hi Peter,

the top line is the start line and is intentionally over extruded.

the middle line looks like filament that hasn't been squished aginst the build plate, because the extruder is too high

and the bottom line looks like raw 1,75mm filament

try Jeff Jordan's 'Life adjust My way' https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html#p97199

there are V6.1 files at the bottom of the first page...

try that when adjusting Live Z...

if the filament is individual strands your extruder is too high, too small a negative number for live Z

If the filament has ripples or waves in the surface, then your extruder is too low, , your live Z value is too big and

If you have a lovely smooth layer with the edges of the filament merging with adjacent filaments, you are about right!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Extrusion issue

Thank you for your reply,

The red strand has a diameter of .55mm; it was extruded from another printer. It is not 1.75mm raw filiment. I put it there to show what scale I'm expecting compared to what I'm getting

The middle line, from my new MK3, is far thinner, 0.25mm, than what I expect from a 0.4mm nozzle.

Even if I get the nozzle close to the bed the plastic does not stick; I believe this is because not enough plastic is being extruded, but I can't figure out why.

When I get the extrusion correct, I should then be able to adjust the z height

Re: Extrusion issue

0.25 mm is too thick string so you have to lower the Z level a bit.

The nozzle diameter is 0.4 mm but the string you are trying to create should be 0.2 mm thick and about 0.45 mm wide.

Then forget the other printer, its nozzle may be larger than 0.4 mm or wrong calibrated.

Bear MK3 with Bondtech extruder

Re: Extrusion issue

Thanks heaps!

While its a surprise to learn that a 0.4mm nozzle extrudes a 0.25mm string, it's a great relief to learn that my new MK3 is extruding correctly.

I'll try again to get the z height correct, so that the plastic sticks to the surface, (the original problem).

Again, many, many thanks

Re: Extrusion issue

If it does not help to calibrate the Z level, you have problems with a dirty bed (grease).

Wash the bed with a dish detergent and water. Wipe with paper and do not touch the writing surface with your fingers.

This works much better than other chemicals.

Between the prints, you can then use 99.5% isopropanol for PLA and window cleaner (Windex) for PETG.

Bear MK3 with Bondtech extruder

Re: Extrusion issue

I've had much more success calibrating the x-height. However, I'm still having issues with the print not sticking to the plate as well as it should. My lastest successful print is a calibration cube. This failed twice before I increased the bed temperature to 70 deg. The now successful print exhibited 'elephant foot' so I'm assuming the nozzle is too low.

I will clean the bed with soap and water as you suggest, and then see if I can print without raising the bed temp, and the nozzle at a better height.

Many thanks