Extruder R3 seems too tight in PTFE tube

So just finished the upgrade to MMU2 and Extruder R3 and when I went to do first layer calibration it failed to put down any filament, so figured I must be clogged. So removed the MMU->Extruder orange PTFE tube and opened the idler door and after heating the hot end up hand pushed some prusa silver PLA through with good result (a wad of PLA came out, and it suddenly started flowing so probably had a clog). I tried the calibration again and it failed, so figured to make it simple I would test just the PLA going direct into the top without the MMU involved to try and isolate. I fed the filament in and the bond tech gears were doing their clicking skipping noise, so pulled the filament out prior to it grinding to pieces. Hand pushed the filament down with the idler door open and note that the path through the PTFE tube into the hot end seems very tight (a lot of drag). I did replace the old PTFE tube as per the directions on the extruder upgrade. I can hand push filament through but the bond tech doesn't seem to be able to. Any ideas. I tried a cold pull with eSun cleaning filament, just in case there was schmutz left in there after the upgrade. I did recheck that the PTFE is firmly seated in the bowden adapter in the V6 and that the collet is locked. The chamfered end of the PTFE is facing up and it's not a problem of seating the filament into the PTFE but that there seems to be a ton of drag on the way through.

Re: Extruder R3 seems too tight in PTFE tube

My hole was just a little bit tight on my self-printed part. About a minute with some metal tools took care of my issues.

I'm unclear if editing the model makes sense, it would be easy to make it too loose.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Extruder R3 seems too tight in PTFE tube

Area51 has this really nice jig to make this a lot easier

When upgrading my MK3 to R3 I changed PTFE tubes as well.

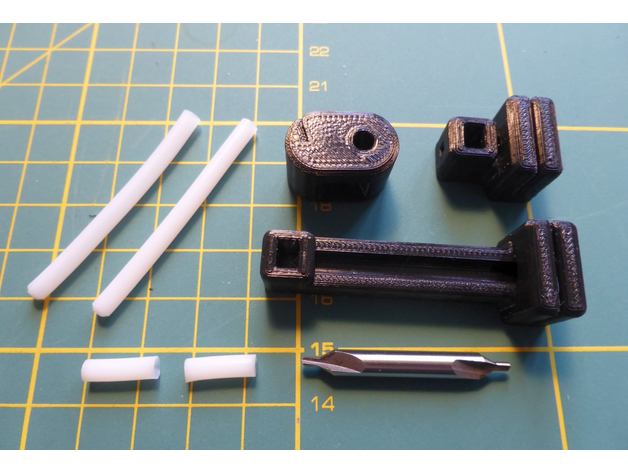

Decided to make a jig for the job:

P1120132 - Thingiverse.jpg

Link to Thingiverse PTFE Tool Jig

Besides the printed parts you will need a hobby knife with 9mm blade and a 60 degree center drill.

BTW your taper (chamfer) looks good 😀